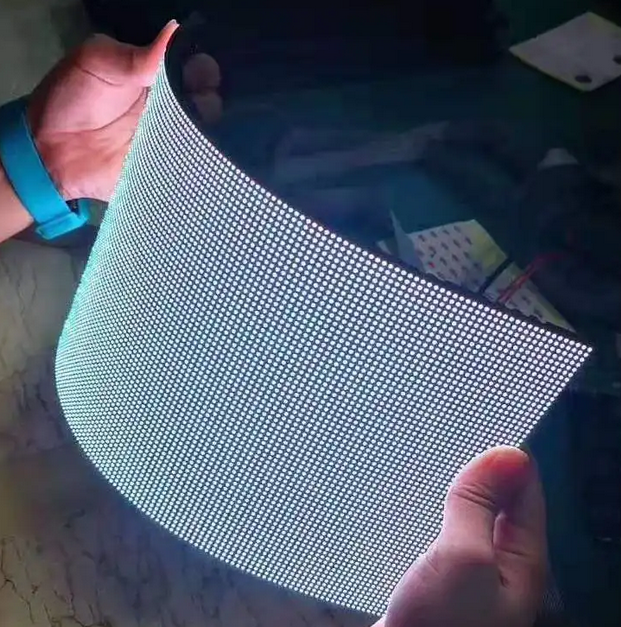

1. Thermal design

LED will heat up when it works, and too high temperature will affect the decay speed and stability of LED, so the heat dissipation design of PCB board and ventilation and heat dissipation design of box will affect the performance of LED.

2. Mixed lamp

LEDs with the same color and different brightness levels need to be mixed or inserted according to the light insertion diagram designed according to the discrete law to ensure the consistency of the brightness of each color on the whole screen. If problems occur in this process, the local brightness of the large screen will be inconsistent, which directly affects the display effect of the LED large screen.

3. Current value is too high

The nominal current of LED is 20mA, and it is generally recommended that its maximum current should not exceed 80% of the nominal value. Especially for large screens with small point spacing, due to poor heat dissipation conditions, the current value should also be reduced. According to experience, due to the inconsistent attenuation speed of red, green and blue LEDs, the current values of blue and green LEDs are purposely reduced to maintain the consistency of white balance after long use of the large screen.

4. Driver circuit design

The layout of the driver IC on the large screen module will also affect the brightness of the LED. Because the drive IC output current is transmitted too far on the PCB, the transmission path voltage drop will be too large, affecting the normal operating voltage of the LED and causing its brightness to decrease. This is why we often find that the LED brightness around the large screen module is lower than that in the middle. Therefore, to ensure the consistency of the brightness of the large screen, it is necessary to design the driver circuit layout.

5. Control the verticality of the lamp

For in-line LED, there should be enough process technology to ensure that the LED is perpendicular to the PCB when passing through the furnace. Any deviation will affect the brightness consistency of the LED already set, and there will be color patches with inconsistent brightness.

6. False welding control

When the LED is not lit on the LED large screen, more than 50% of the probability is caused by various types of faulty soldering, such as LED pin faulty soldering, IC pin faulty soldering, row pin and row bus faulty soldering. These problems need to be solved by strictly improving the process and strengthening the quality inspection. Vibration test before delivery is also a good inspection method.

7. Wave soldering temperature and time exceeded

The temperature and furnace passing time of wave front welding must be strictly controlled. It is recommended that the preheating temperature should be 100 ℃± 5 ℃, and the maximum temperature should not exceed 120 ℃. The preheating temperature should rise steadily. The welding temperature should be 245 ℃± 5 ℃, and the welding time should not exceed 3 seconds. After furnace passing, do not vibrate or impact the LED until it returns to normal temperature. The temperature parameters of the wave soldering machine should be detected regularly, which is determined by the characteristics of the LED. Overheating or fluctuating temperature will directly damage the LED or cause potential quality problems, especially for small size round and oval LEDs, such as 3mm.

8. Antistatic

The LED large screen assembly plant shall have good anti-static measures. Special anti-static ground, anti-static floor, anti-static soldering iron, anti-static platform mat, anti-static ring, anti-static clothing, humidity control, equipment grounding (especially foot cutting machine), etc. are basic requirements, and should be tested regularly with an electrostatic meter.