Table of Contents

-

Principles: Internal Structure, Signal Flow, and Thermal Design Logic

-

Key Parameters and Tolerance Control

-

Design Considerations: Structure, Tolerance, Thermal, Waterproofing, Power, and Electrical Safety

-

Manufacturing Process and Quality Control

-

Application Variations and Failure Modes (FMEA)

-

Supply Chain and Procurement Recommendations

-

Conclusion

1. Principles: Internal Structure, Signal Flow, and Thermal Design Logic

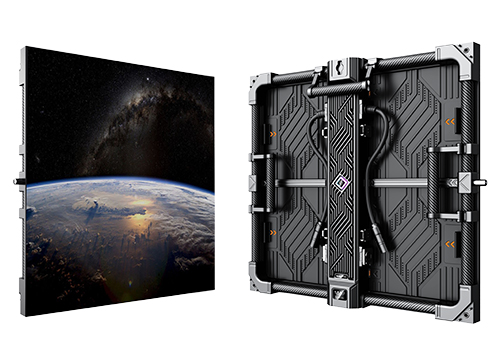

The LED display cabinet is the mechanical, electrical, and thermal backbone of a display system. Its design must satisfy modularity, high precision, durability, and long-term reliability.

a. Structural Breakdown and Design Logic

Cabinet Materials

Mainstream materials include die-cast aluminum alloy and magnesium alloy.

Die-Cast Aluminum

The optimal choice for rental screens and fine-pixel-pitch indoor displays due to its rigidity, lightweight characteristics, and excellent thermal conductivity. Structural reinforcement ribs must be carefully designed to reduce torsion and long-term deformation.

Extruded Profiles

More cost-effective and commonly used in large traditional outdoor fixed installations.

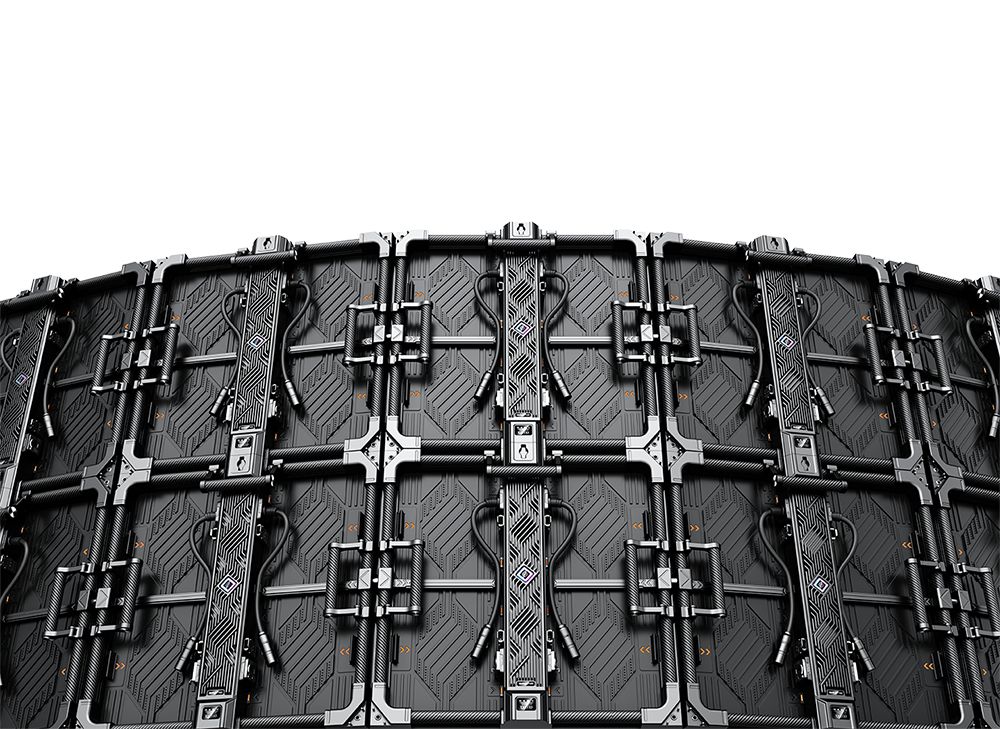

Positioning System

A combination of dowel pins and fast locks:

-

Dowel Pins → Control XY-plane flatness and alignment

-

Fast Locks → Eliminate gaps and ensure rigid mechanical mating

Tolerance Objective:

Cabinet-to-cabinet splicing tolerance must be controlled within ±0.1 mm or even lower to maintain seamless visual alignment.

b. Signal Chain and Power Distribution

Data Transmission

Uses high-speed flat ribbon cables or custom wiring harnesses.

Critical Considerations:

-

Maintain signal integrity (SI) through impedance-matched routing

-

Avoid long parallel signal traces

-

Ensure continuous ground return paths to suppress EMI/RFI

Redundancy

Signal and power ports (typically HUB boards) should support redundancy or loop-through options to enable hot backup.

Power Distribution

-

Low-voltage, high-current systems (5V/12V)

-

Copper busbars or large copper pours are essential to minimize losses:

P=I2RP = I^2RP=I2R

Voltage Uniformity

Multi-point power injection is recommended to ensure even voltage across the PCB.

c. Thermal Design Logic

LED performance and lifetime are directly tied to junction temperature (Tj). Thermal design is a central factor in system reliability.

Primary Heat Sources:

-

LED chips

-

Driver ICs

Thermal Path

-

LED junction

-

LED package

-

Encapsulation material

-

PCB copper layer

-

Cabinet backplate or baseplate

Conduction + Convection

-

Conduction removes heat from PCB to cabinet

-

Convection removes heat from the cabinet into surrounding air

Key Thermal Elements

Cabinet Backplate

Should have high-density heat-sink fins to maximize surface area.

Die-cast aluminum’s thermal conductivity (150–200 W/m·K) is essential.

Thermal Interface Materials (TIM)

Thermal pads or grease between PCB and cabinet must have extremely low thermal resistance:

Rth<0.5 K/WR_{th} < 0.5\, \text{K/W}Rth<0.5K/W

Cooling Systems

-

Fanless design → common for indoor and rental screens

-

Forced-air cooling → used for large high-brightness outdoor screens

2. Key Parameters and Tolerance Control

a. Engineering Parameter Table

| Category | Parameter | Unit | Indoor Fine-Pitch | Rental/Outdoor High Brightness | Standard/Target |

|---|---|---|---|---|---|

| Structural | Splicing Flatness Tolerance | mm | ≤ ±0.05 | ≤ ±0.1 | ISO 2768-m |

| Diagonal Error | mm | ≤ 0.2 | ≤ 0.3 | GD&T | |

| Thermal | Cabinet Temp Rise (ΔT) | K | ≤ 15 | ≤ 25 | Surface temp ≤ 55°C |

| TIM Thermal Resistance | K/W | ≤ 0.4 | ≤ 0.5 | Ultra-low Rth | |

| Electrical | Voltage Ripple | mVp-p | ≤ 50 | ≤ 100 | Avoid IC interference |

| Power Density | W/m² | 300–600 | 600–1000+ | Drives thermal strategy | |

| Protection | IP Rating | — | IP30 | IP65–IP67 | IEC 60529 |

3. Design Considerations: Structure, Tolerance, Thermal, Waterproofing, Power, Electrical

a. Structural & Tolerance Design

Modularity & Maintainability

Fine-pitch displays often use magnetic modules requiring extremely high consistency between:

-

Magnetic force

-

Guiding slots

-

PCB connectors

Tolerance Stack-Up Analysis

Accumulative tolerances from:

Module frame → PCB → Cabinet skeleton → Pins → Locks

must remain below the final target splicing tolerance.

Material Rigidity

Young’s modulus and yield strength must support hanging, stacking, and long-term loads without plastic deformation.

b. Thermal and Waterproofing Design

Outdoor Waterproofing

Sealing system uses:

-

Elastomer gaskets

-

Groove structures

Compression ratio must be precisely calculated:

Too low → leakage

Too high → cabinet deformation & accelerated aging

Breather Valves

A critical component for outdoor displays:

-

Releases humid air and balances pressure

-

Prevents condensation

-

Blocks external water ingress

c. Power & Electrical Safety

EMC/EMI

Shielding:

The cabinet should act as a Faraday cage. Shielded cables are required, with proper grounding.

Filtering:

Power entry requires EMI filters (common-mode and differential-mode chokes).

Grounding:

Single-point grounding + supplemental grounding.

Ground resistance < 4 Ω.

4. Manufacturing Process and Quality Control

a. SMT Key Steps

Solder Paste Printing

Laser-cut stencils with optimized thickness ensure proper solder volume and coplanarity.

Reflow Profile

Must be tuned for LED package temperature limits to prevent:

-

Gold wire oxidation

-

Package deformation

X-Ray Inspection

Necessary for BGA/QFN driver ICs and small-pitch LED packages.

b. Assembly Process

Cabinet Calibration

Before installing modules, empty cabinets must be checked on CMM or precision jigs.

Module Installation

-

Torque-controlled screws to prevent PCB warping

-

Flatness calibration using specialized alignment tools

-

Electrical connection verification for each connector

c. Aging Tests & QC Stages

| QC Stage | Inspection | Tools | Dept |

|---|---|---|---|

| IQC | Die-cast tolerances | CMM, gauges | Structure/QC |

| LED binning | Spectrometers | Electronics | |

| IPQC | SMT checks | X-ray, AOI | Process/QC |

| Torque verification | Torque wrench | Assembly | |

| FQC | White balance, brightness, chromaticity | Color analyzers | Electronics |

| Cabinet splicing accuracy | Alignment tools | Structural | |

| Aging | 48–72h high/low-temp cycles | Test chambers | QC |

| OQC | IP testing | Rain simulation, vacuum tests | QC |

5. Application Variations & Failure Modes (FMEA)

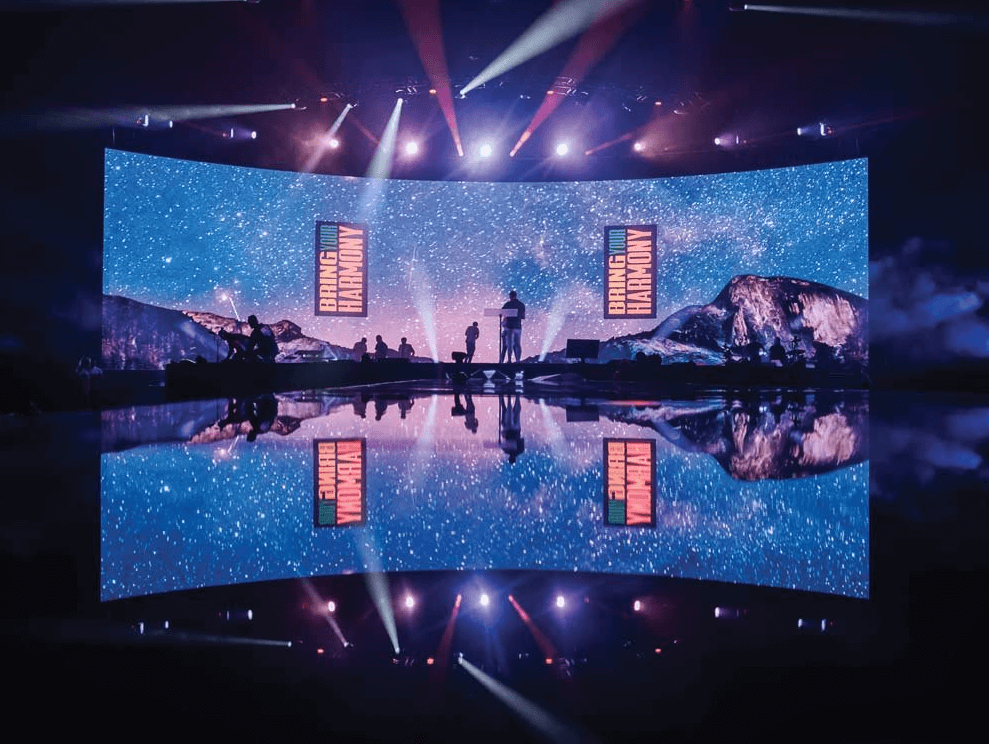

a. Application Variations

| Scenario | Environment | Core Requirements |

|---|---|---|

| Middle East / Desert | High heat, sand | 200%+ thermal margin; IP67; anti-corrosion coating |

| Coastal / High Humidity | Salt mist | Conformal coating; anti-corrosion; IP65 power connectors |

| Stadiums | Vibration, wind load | High rigidity; redundant signal/power; >8000 nits |

| Shopping Malls / XR | Controlled indoor | Fine pitch (<±0.05 mm tolerance); fanless; low light/low noise |

b. FMEA

| Failure Mode | Cause | Effect | Prevention |

|---|---|---|---|

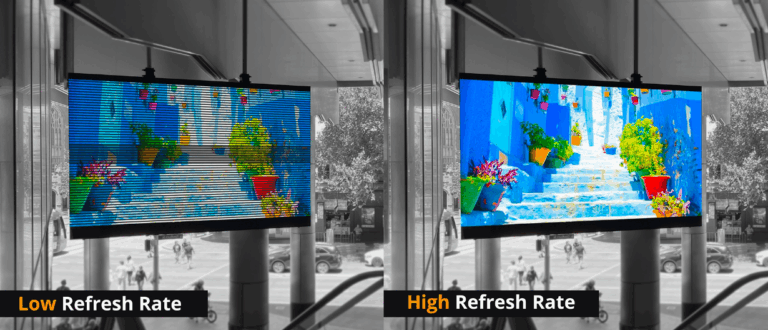

| “Caterpillar” artifacts / bright/dark lines | Impedance mismatch; ground loop break | Distorted image, vertical/horizontal lines | PCB impedance control; shielded cables; high-quality connectors |

| Splicing black/bright lines | Cabinet tolerance out of spec; module stress | Visible seams | Strict die-cast tolerance control; uniform torque; CMM calibration |

| LED pixel dropout | Heat cycling, solder fatigue | Dead pixels | Optimized reflow; strict aging |

| Water ingress | Gasket failure | Short circuits | Correct gasket compression; valve design |

| Color shift | LED binning inconsistency | Patchy colors | Strict LED bin control |

6. Supply Chain & Procurement Recommendations

-

Choose suppliers with CMM-verified die-cast processes

-

Require LED binning reports (color wavelength, brightness)

-

Confirm availability of EMC-certified power supplies

-

Ensure full documentation: BOM, stack-up drawings, tolerance table

-

Verify aging test reports before shipment

7. Conclusion

The LED cabinet is far from a simple mechanical enclosure—it is a tightly integrated structural, electrical, and thermal system. High-precision tolerance control, thermal-path optimization, robust waterproofing, and rigorous quality processes are the foundation of long-term reliability. As pixel pitch continues shrinking and application environments diversify, cabinet engineering becomes even more critical to overall display performance.

References: