At a major concert in Shanghai, a rental LED display suddenly went partially dark. After urgent troubleshooting, the onsite technicians discovered that an internal bonding wire inside one of the LED lamp beads had snapped. A tiny wire—thinner than a third of a human hair—halted an entire live performance and left the rental company with tens of thousands of dollars in repair costs and reputation damage.

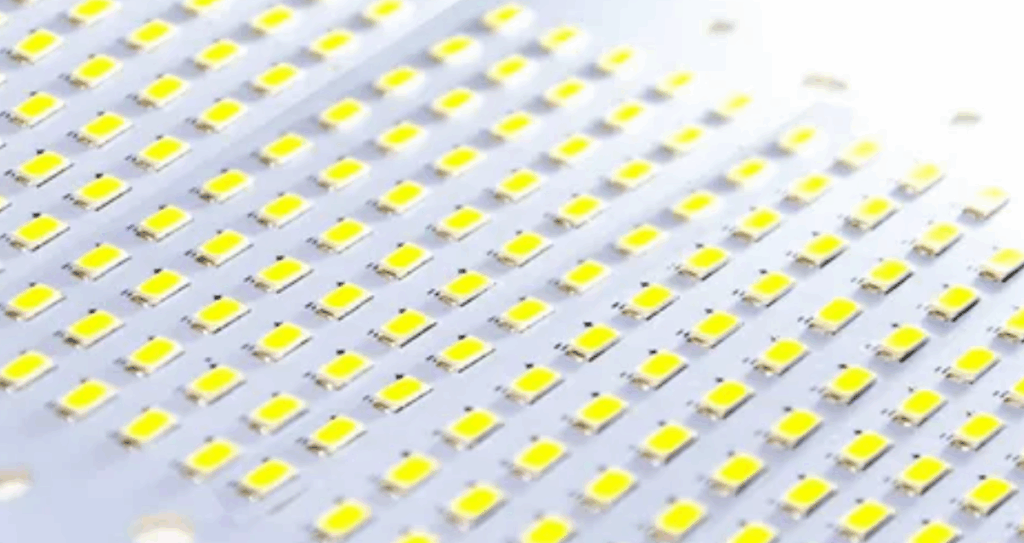

In the LED display industry, lamp beads are the heart of the system, and the choice of bonding wire—gold, silver, or copper—directly defines the reliability and lifespan of the display. As a factory specializing in commercial fixed installations and rental-stage LED solutions, Sostron breaks down the technical characteristics of each bonding wire material to help you make the right selection.

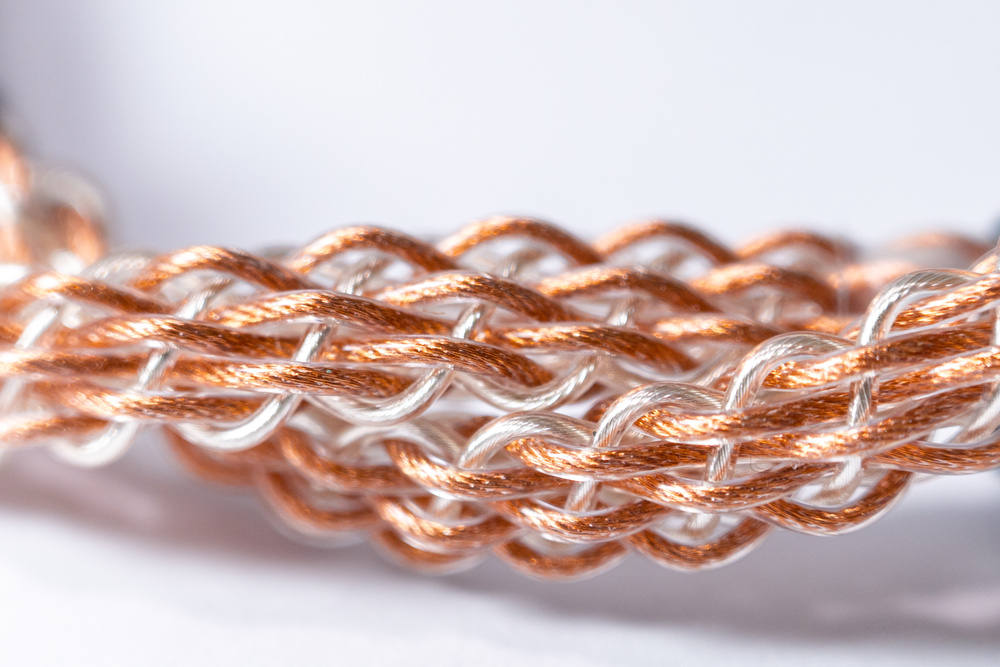

Inside the Micro World of Bonding Wires: What Truly Sets Each Material Apart

Bonding wires inside LED lamp beads measure only 20–30 microns in diameter—about one-third the thickness of a hair—yet they carry current and connect the LED chip to the outside world.

Under high magnification:

-

Gold wire shows a uniform crystalline structure.

-

Silver wire features a protective anti-oxidation coating.

-

Copper wire relies on electroplating to achieve a smooth, stable surface.

Gold wire remains the preferred choice for high-end LED displays thanks to its 98% conductivity and excellent ductility. In a 1,000-cycle thermal stress test (-40°C to 85°C), gold wire shows only a 0.3% breakage rate, thanks to its strong fatigue resistance.

Silver wire offers slightly higher conductivity (99%), but suffers from ion migration in hot and humid environments, which can create uneven brightness over time.

Copper wire, now improved through modern plating technology, reduces material costs by 40% while offering 97% conductivity. However, copper is more sensitive to soldering conditions and requires a narrow temperature window of 220–240°C to avoid weak joints.

Reliability Test Results: From the Lab to Real-World Performance

Sostron subjected all three bonding wire types to 1,000 hours of accelerated aging. In harsh 85°C / 85% RH conditions:

-

Gold wire LED beads: 8% light decay

-

Silver wire LED beads: 12% light decay

-

Copper wire LED beads (optimized): 10% light decay

This means a copper-wire LED screen can still retain over 70% brightness after five years outdoors in high-temperature climates.

During vibration testing—simulating bumpy transport in flight cases (5–500 Hz, 10G):

-

Gold wire LEDs: 99.5% survival

-

Silver wire LEDs: 98.2%

-

Copper wire LEDs: 97.8%

This is why high-end rental screens almost always use gold-wire LEDs—they withstand repeated installation, teardown, and long-distance shipping with far fewer failures.

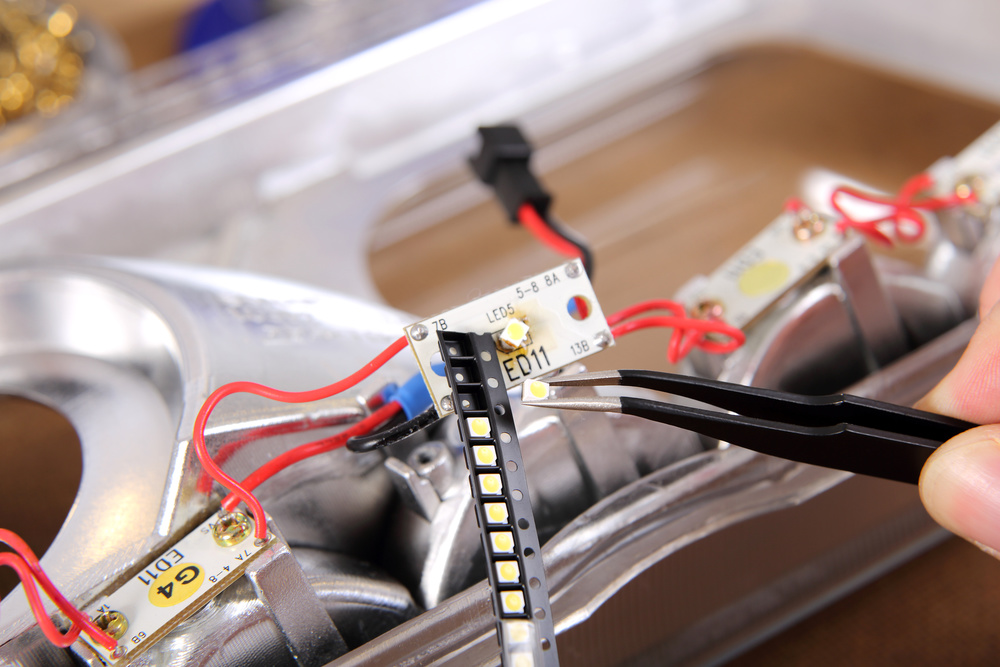

The Soldering Process: The Final Step That Determines Long-Term Reliability

Bonding wire reliability depends heavily on how it is soldered to the LED bracket.

Sostron uses a eutectic soldering process that forms a strong intermetallic bond between the gold wire and the bracket, achieving over 15 grams of pull strength. Traditional solder-paste joints tend to concentrate stress at the wire root, increasing the likelihood of long-term fractures.

Copper wire soldering demands tighter process control. By using nitrogen protection and pulse heating, we improved the soldering yield from 85% to 99.2%. Every lamp bead undergoes pull testing and X-ray inspection to eliminate voids and cracks.

This level of rigor helps explain why our outdoor screens at Canton Tower in Guangzhou continued running flawlessly—even through typhoon weather.

Application-Based Selection Guide: Match Technical Specs to Real Needs

Different installation environments require different bonding wire choices.

Outdoor Fixed Installations

We recommend gold wire LEDs, paired with:

-

IP65 protection

-

UV-resistant masks

-

Operating range of –30°C to 60°C

For a P3.91 outdoor LED display, gold wire can extend usable life to over 8 years, while adding only about 12% to material cost.

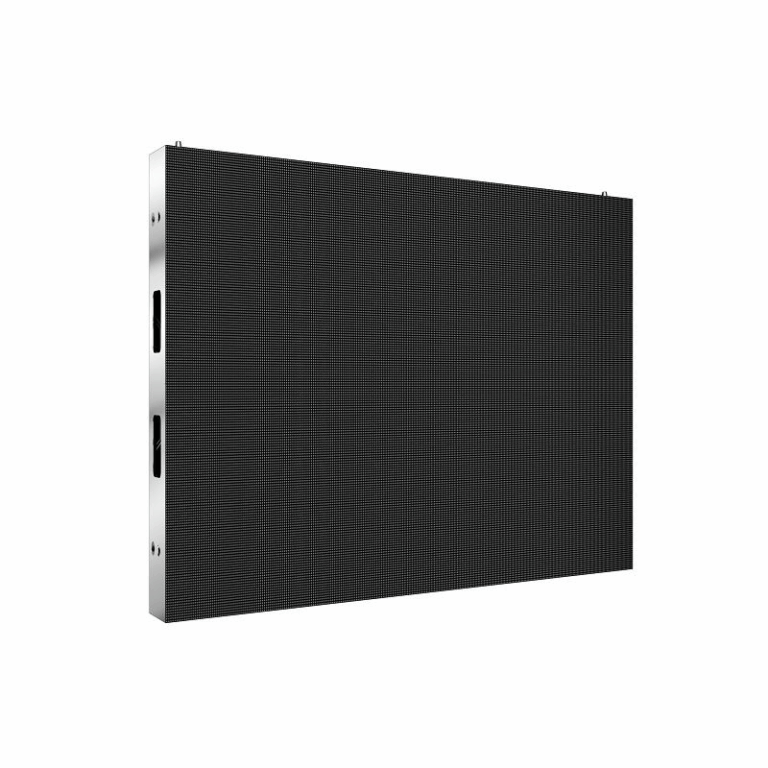

Rental Applications

Here, reliability and cost must be balanced.

Sostron’s rental displays use high-performance copper-wire LEDs, paired with:

-

Fast-lock systems

-

Corner protection

-

3,840 Hz refresh rate

-

Lightweight 7.5 kg modules

At an international auto show, our team installed and calibrated 200 m² of LED screens in just 4 hours—a result of pairing the right LED beads with the right structure.

Comparison Table: Key Metrics at a Glance

| Technical Metric | Gold Wire LED | Silver Wire LED | Copper Wire LED (Optimized) |

|---|---|---|---|

| Conductivity | 98% | 99% | 97% |

| Cost | High | Medium-high | Budget-friendly |

| Soldering Yield | 99.5% | 98.8% | 99.2% |

| 1,000h Light Decay | 8% | 12% | 10% |

| Vibration Resistance | Excellent | Good | Good |

| Recommended Use | Outdoor fixed / High-end rental | Indoor HD displays | Mid-range rental / Indoor fixed |

| Product Series | S-Pro | S-HD | S-Eco |

Engineer’s Tips: Practical Know-How the Industry Rarely Tells You

1. Selecting the Best Value: Use the TCO Formula

Total Cost of Ownership (TCO) = Initial Cost + (Annual Failure Rate × Maintenance Cost × Years of Use)

For a 500 m² indoor P2.5 project, copper wire may be 25% cheaper upfront, but with a 1.2% annual failure rate, gold wire ends up with the lower TCO—especially in major cities where labor is expensive.

2. Heat Dissipation: The Silent Killer of LED Lifespan

Lowering LED operating temperature by 10°C doubles its lifespan.

Recommended formula:

Heat dissipation area (m²) = LED power consumption (W) × 0.005

A 1,000W outdoor screen needs at least 5 m² of effective cooling surface.

Sostron’s wave-shaped heat-sink fins improve cooling efficiency by 40% compared to flat designs, keeping LED junction temperatures below 70°C.

3. Quality Verification: What Certifications You Should Ask For

When evaluating LED lamp beads, request these test reports:

-

Thermal cycling: –40°C to 85°C, 1,000 cycles

-

Humidity: 85°C / 85% RH, 1,000 hours

-

Mechanical shock: 1500G, 0.5 ms

-

Luminous maintenance: 70% @ 50,000 hours

Only products that meet these benchmarks can ensure long-term stability.

Sostron’s Quality Commitment: Full Control from Lab to Installation Site

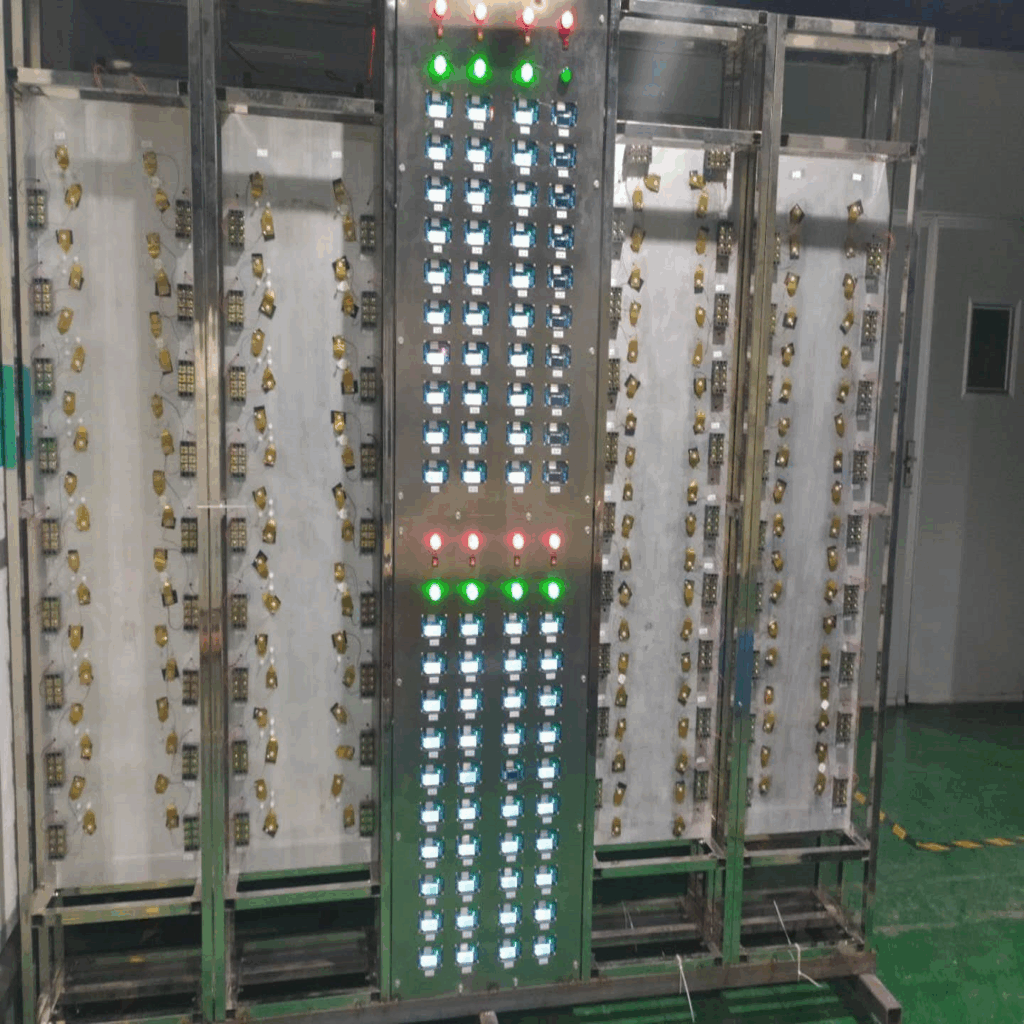

As an original factory, Sostron offers not only LED modules but complete end-to-end solutions. Each batch of LEDs undergoes 72-hour high-temperature aging to eliminate early failures.

During the 2023 Hangzhou Asian Games, our backup modules, power supplies, and receiving cards helped resolve emergency issues during the opening ceremony—keeping the event’s giant LED systems running flawlessly.

Our products carry CE, RoHS, ETL, and FCC certifications, ensuring compliance with environmental and EMC standards worldwide. With spare-parts centers in Germany, the U.S., and Singapore, we guarantee 24-hour response for customer support.

Final Word: Choosing Lamp Beads Is Not Only a Technical Decision—It’s a Business Decision

Gold wire offers maximum reliability.

Silver wire delivers strong performance for indoor HD applications.

Copper wire provides the best cost efficiency—when paired with a controlled production process.

With 15 years of industry experience, Sostron is ready to help you strike the ideal balance between performance and budget.

Contact us today for a free LED screen selection consultation and complete CAD drawings for your project.

Let’s build a breathtaking visual experience together.

References: