Table of Contents

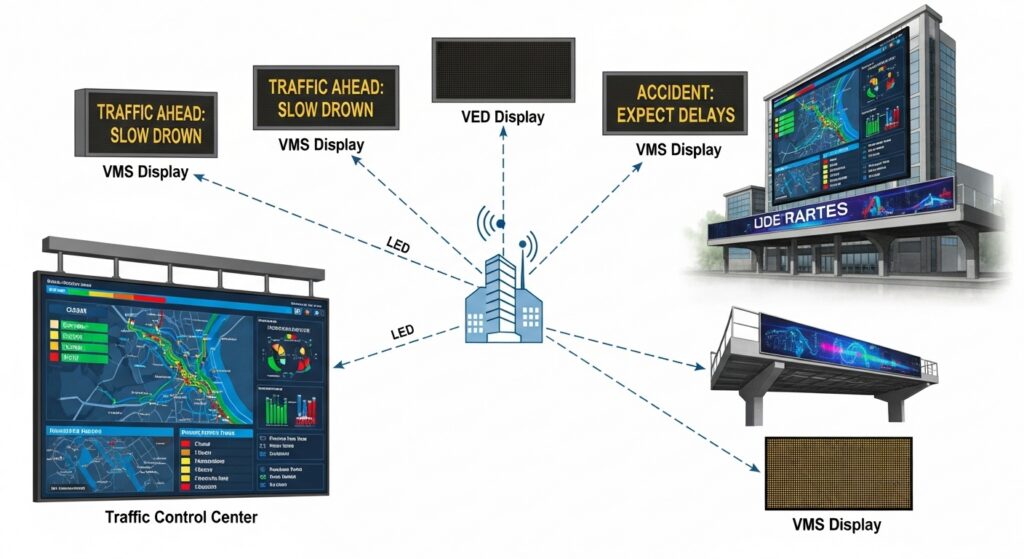

ToggleIn modern smart city systems, traffic guidance LED displays—commonly known as Variable Message Signs (VMS)—are defined as the terminal feedback units of the road’s nervous system.

At their core, these systems integrate real-time traffic data, meteorological sensing, and high-contrast optoelectronic display technologies to keep information transmission latency under 100 milliseconds. This ensures that drivers can still clearly read critical decision-making information from 200 meters away at speeds of up to 120 km/h (75 mph).

For international procurement managers and manufacturing engineers, the purchasing focus has long shifted—from “Does it light up?” to “How long can it run stably under extreme heat and high-salinity conditions?”

According to the latest ITS (Intelligent Transportation Systems) industry white paper, the global average annual failure rate of traffic display equipment caused by environmental corrosion reaches 12.4%.

Backed by 14 years of R&D experience and stress-test data from a 4,000㎡ R&D center, Sostron is committed to reducing this failure rate to below 0.1% through common-cathode energy-saving technology and full-aluminum protective structures.

Why Do 14-Year-Experienced Factories Prioritize “24/7 All-Weather Stability”?

In traffic guidance applications, a single black screen or dead pixel issue doesn’t just cause congestion—it can lead to serious safety incidents.

Based on real-world experience from the Brazil Highway Project (P5 pixel pitch), traffic environments impose exceptionally strict requirements on LED displays.

Survival Rules in Extreme Climates

Traffic VMS are typically installed on highway gantries or fully exposed intersections, enduring long-term exposure to strong UV radiation, high temperatures, and high humidity.

Thermal Management Challenges

Traditional steel cabinets can reach internal temperatures of up to 80°C (176°F) under direct summer sunlight.

Sostron Storm Pro (high-end die-cast outdoor series) adopts a full-aluminum structure, improving heat dissipation efficiency by over 30% compared to industry averages.

Protection Levels

Simply meeting IP65 is not enough.

Sostron’s traffic guidance series uses double-sided potting protection, ensuring that even in tropical rainforests or coastal high-salt environments, circuit boards are protected from electrochemical migration and short circuits.

Quality-Control Closed Loop from a 14-Year Intelligent Manufacturing Base

As a National High-Tech Enterprise, Sostron has established an industry-leading QC process in its 15,000㎡ intelligent manufacturing facility.

Every traffic guidance display must pass:

-

72-hour high-temperature & high-humidity aging tests

-

10,000 simulated vibration cycles (replicating bridge vibration caused by heavy vehicles)

-

Extreme brightness degradation simulations

Performance Standards Comparison

| Performance Metric | Industry Standard | Sostron Traffic Standard | Practical Value |

|---|---|---|---|

| Operating Temperature | -20°C to +50°C | -40°C to +75°C | Covers climates from Siberia to the Sahara |

| Max Brightness | 5,000 nits | Up to 10,000 nits | Maintains L3 contrast under direct sunlight |

| Cabinet Material | Painted steel | Die-cast aluminum / full aluminum | 40% lighter, zero rust risk over 10 years |

| Energy Efficiency | Standard power supply | Common-cathode (50% energy savings) | Significantly reduces electricity costs |

Key Technical Parameters Explained: A Must-Read for Procurement Managers & Engineers

When selecting technical specifications, engineers should look beyond individual LED chip brands and focus on system-level compliance and protocol compatibility.

Brightness vs. Contrast Ratio Balance

For traffic displays, brighter is not always better.

Excessive brightness at night can cause glare and compromise driving safety.

Sostron follows EN12966 (European Road Traffic Sign Standard) and enhances contrast through a specialized mask design.

Technical Highlight:

A matte, non-reflective coating ensures clear readability even at low sun angles, achieving the highest R3 contrast class.

Control Systems & Protocol Compatibility (NTCIP / Modbus / Cloud Alerts)

Modern traffic VMS must combine hardware reliability with intelligent software integration.

-

Remote Diagnostics

Sostron’s CMS supports proactive fault alerts. In African “crossroad” highway projects, operators can remotely monitor power supplies, individual LEDs, and ambient temperature—eliminating routine manual inspections. -

Multi-Protocol Integration

Full support for NTCIP and Modbus, enabling seamless integration with existing traffic control systems, including radar speed detection linkage displays.

ARES 2 Series: Redefining Energy-Efficient Traffic Flagships

For long-term projects with tight budgets but uncompromising quality requirements, the ARES 2 Series adopts flagship-level common-cathode driving technology.

Core Advantage:

By lowering the voltage of red LED chips, heat generation is reduced by 50%.

This not only cuts electricity bills in half but also lowers component operating temperatures—extending MTBF (Mean Time Between Failures) by a full 2 years.

Four Core Application Scenarios: From Highways to the Urban Core

Based on Sostron’s global delivery experience, different scenarios place emphasis on different LED performance priorities.

Highway / Freeway

The most traditional—and most demanding—VMS application.

Technical Focus: Long-distance visibility

Recommended pixel pitches: P10 or P16 high-brightness modules

Sostron Solution:

In the Cairo Highway Project (Egypt), ultra-high-contrast masks ensured sharp text edges with zero ghosting—even under intense Sahara UV exposure.

Urban Intersections & Traffic Guidance

Urban road networks are complex, with high-frequency information updates.

Technical Focus: High refresh rate & dynamic content updates

Sostron Solution:

Integrated with CMS cloud control, displays dynamically adjust direction arrows and congestion alerts based on real-time traffic center data—optimizing road right-of-way allocation.

Tunnel Safety & Emergency Evacuation (Tunnel VMS)

Tunnel environments are confined and exposed to exhaust corrosion and persistent humidity.

Technical Focus: Flame retardancy & moisture resistance

Recommended Product: Storm Series (full aluminum cabinet)

Its all-metal housing enhances heat dissipation and achieves high fire-resistance ratings, allowing displays to operate longer during emergencies and guide safe vehicle evacuation.

Intelligent Parking Guidance

The “last 100 meters” of smart city mobility.

Technical Focus: Slim profile & easy maintenance

Sostron Solution: Storm Plus Indoor Fixed Series

Only 51 mm thick, supports full front maintenance, and installs easily in underground malls or transport hubs to display real-time parking availability.

ROI Analysis: Why Choosing Sostron Is a Smart Financial Decision

For factory owners and procurement managers, initial purchase cost is only the tip of the iceberg—long-term operation and maintenance dominate total expenditure.

Operating Cost Comparison (100㎡ Outdoor Display Example)

| Cost Factor | Traditional LED Solution | Sostron Ares 2 (Common Cathode) | 5-Year Savings / Value |

|---|---|---|---|

| Annual Power Consumption | ~350,000 kWh | ~175,000 kWh | Electricity savings of $80,000+ |

| Cooling & Fan Maintenance | High-power fans required | Fanless silent cooling | Lower failure & cleaning costs |

| Brightness Degradation | 10–15% per year | <5% per year | Extends service life by 2–3 years |

| Inspection Labor | On-site manual checks | CMS cloud alerts | 70% reduction in site visits |

Real-World Validation: Brazil Highway Project

In a P5 highway project near São Paulo, the client initially worried about electricity costs.

Sostron delivered a custom common-cathode solution, and monitoring data showed 48% lower power consumption at the same brightness level.

Result: The client recovered the premium investment within just 18 months—from electricity savings alone.

Expert Insights: 3 Frequently Asked Questions About Traffic VMS

Based on recurring questions from our technical support team:

Q1: Why can’t standard outdoor advertising LED screens be used as traffic displays?

A: The key difference lies in optical performance.

Advertising screens prioritize vivid colors, while traffic displays focus on high contrast and luminance uniformity in mono- or dual-color modes.

Additionally, traffic displays must support specific communication protocols such as NTCIP to integrate with government ITS platforms—capabilities standard advertising screens lack.

Q2: How do you address salt corrosion in coastal cities?

A: Enclosure protection alone is insufficient.

Sostron applies a triple-protection strategy:

-

Conformal coating

-

Fully sealed aluminum cabinets

-

Gold-plated connectors

In southern France coastal projects, Ares Series displays have operated for 5 years with zero internal corrosion, thanks to intentionally “over-engineered” protection standards.

Q3: How is fast repair handled if pixels fail on a highway display?

A: Storm Pro and Ares 2 support dual front & rear maintenance.

For gantry-mounted screens, technicians can quickly replace modules or power supplies from the rear—without dismantling the cabinet.

Combined with CMS alerts, the system sends notifications before large-scale pixel failures occur, enabling true preventive maintenance.

Conclusion: The Future of Smart Traffic Is Data-Driven Visual Terminals

By 2026, traffic guidance displays are no longer simple electronic signboards—they are physical representations of urban data.

Choosing a supplier with 14 years of expertise, 4,000㎡ R&D capability, and National High-Tech Enterprise certification means you’re not just buying hardware—but a complete system defined by:

-

Long-term stability

-

Extreme environmental adaptability

-

Ultra-low operational and maintenance costs

Next Step

Are you planning a traffic, stage, or commercial display project?

👉 Contact Sostron’s senior engineers.

We’ll provide a free customized technical proposal and quotation, tailored to your installation location, local climate data, and system integration requirements.

References:

NTCIP — National Transportation Communications for ITS Protocol

MUTCD — Manual on Uniform Traffic Control Devices

About Dylan Lian

Marketing Strategic Director at Sostron