Catalogue

LED Cube is LED Rubik’s cube screen

LED Cube Overview

LED cube price

LED cube application scenario

How to make LED cubes

LED cube installation structure

Installation steps of LED cube

LED Cube is LED Rubik’s cube screen

The LED cube consists of six LED faces combined into a cube, which can also be special-shaped spliced into a geometric shape, and the minimum gap between the faces is realized.

It is very simple to use. Users simply plug the device into a power source and connect to Wi-Fi via the phone APP. Users can choose pictures and text for editing and production. Flexible display and rich theme templates also allow users to easily create their own unique style. Do you understand the characteristics of LED cubes?

LED Cube Overview

1. The LED cube is composed of ED unit board and square steel structure, and its display effect is better.

2. The unit board is composed of a light emitting diode and a drive circuit plus a drive IC and a plastic kit.

3, the model of the LED cube is basically named after the pixel spacing, which is basically the same as the conventional led display.

4, its module is similar to the conventional LED display, the main models are P2, P2.5, P3, P4 and so on.

LED cube price

The price of LED cubes depends mainly on their quality, size and pixel pitch. In general, the price of LED display is between 1,000 and 10,000 US dollars per square meter.

LED cube application scenario

LED cube because its shape is more unique, can achieve a more fashionable display effect, is mainly used in some science museum, terminal, museum, exhibition hall, hotel, Di bar, stage scene, indoor shopping malls, city squares and so on.

How to make LED cubes

Design and planning: First of all, according to the size and requirements of the LED cube, design and planning. Determine screen size, resolution, display effect and other parameters.

LED module preparation: Select the appropriate LED module, which is usually composed of LED lamp beads, circuit boards, driver chips, etc. Ensure module quality and performance meet requirements.

Splicing and assembly: The LED module is spliced and assembled into the overall structure of the LED cube according to the planned size and arrangement.

Control system: Prepare the control system, including display control card, signal processor, etc. Ensure that the display content and effect of the LED screen can be controlled.

Outer frame and bracket: Make the outer frame and bracket of the LED cube to ensure the stability and security of the screen.

Bead correction: Perform LED bead correction to ensure consistent color and brightness between modules.

Overall debugging: After the completion of assembly, the LED cube is overall debugging and testing to ensure the normal operation of the display effect and function.

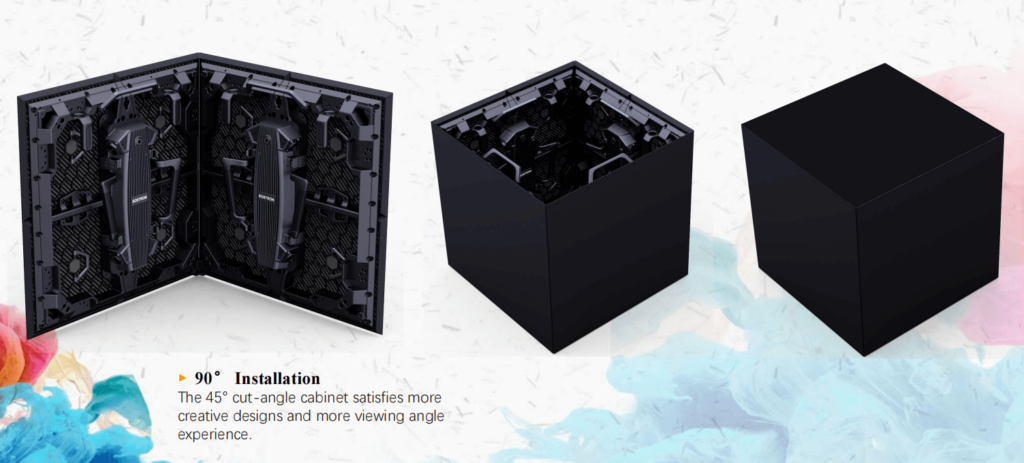

LED cube installation structure

It mainly includes frame, control card, LED display module, power board, wiring, control software, power cord and so on.

LED cube installation steps

Determine the installation location: Before installation, determine the installation location of the LED cube, and evaluate the installation environment to ensure that the installation area is smooth and stable, and meets the relevant safety requirements.

Installation bracket: According to the design and planning, install the bracket of the LED cube. The support can be a lifting, wall fixed or ground support to ensure that the support is stable and reliable.

Connect the power supply: Connect the power cord of the LED cube to the power interface to ensure that the power connection is correct, stable and reliable, and pay attention to waterproof and insulation treatment.

Connect the data line: Connect the data line of the LED cube to the display control card or signal processor to ensure normal data transmission.

Lamp bead correction: LED lamp bead correction to ensure that the display effect is uniform, color and brightness meet the requirements.

Test and debug: test and debug the LED cube, ensure the display effect and function run normally, adjust the parameters and Settings.

Fixed installation: The LED cube is fixed in the installation position, and the bracket and screen are firmly connected together using screws or fixing devices.

Power supply: Connect the power supply of the LED cube to ensure stable power supply.

Adjust brightness and color: According to the actual environment and display requirements, adjust the brightness, color and other parameters of the LED cube to achieve the best display effect.

Final test: After the installation is complete, the final test is performed to ensure that the LED cube is working properly at the installation location.