Table of Contents

ToggleTable of Contents

-

What Are Low-Voltage Power Solutions for Fine-Pitch LED Screens?

-

Comparing the Performance of 2.8V, 3.8V, and 5V Power Solutions

-

How Low-Voltage Solutions Achieve “Low Brightness, High Gray” Visuals

-

Long-Term Reliability and Maintenance Costs of Low-Voltage Solutions

-

How to Choose the Right Low-Voltage Power Solution

Fine-pitch LED screens with low-voltage power solutions—such as 2.8V and 3.8V—use precise matching of the actual forward voltage of red, green, and blue LED chips to reduce power consumption and heat generation. Compared to traditional 5V constant-voltage systems, these low-voltage solutions significantly improve energy efficiency, extend screen lifespan, and provide the hardware foundation for ultra-low-power, high-reliability products like Sostron’s Ares series.

What Are Low-Voltage Power Solutions for Fine-Pitch LED Screens?

As the LED display industry pushes fine-pitch technology down to P1.0 and smaller pixel pitches, managing heat dissipation and power consumption in these high-density panels becomes a key measure of a manufacturer’s technical capability.

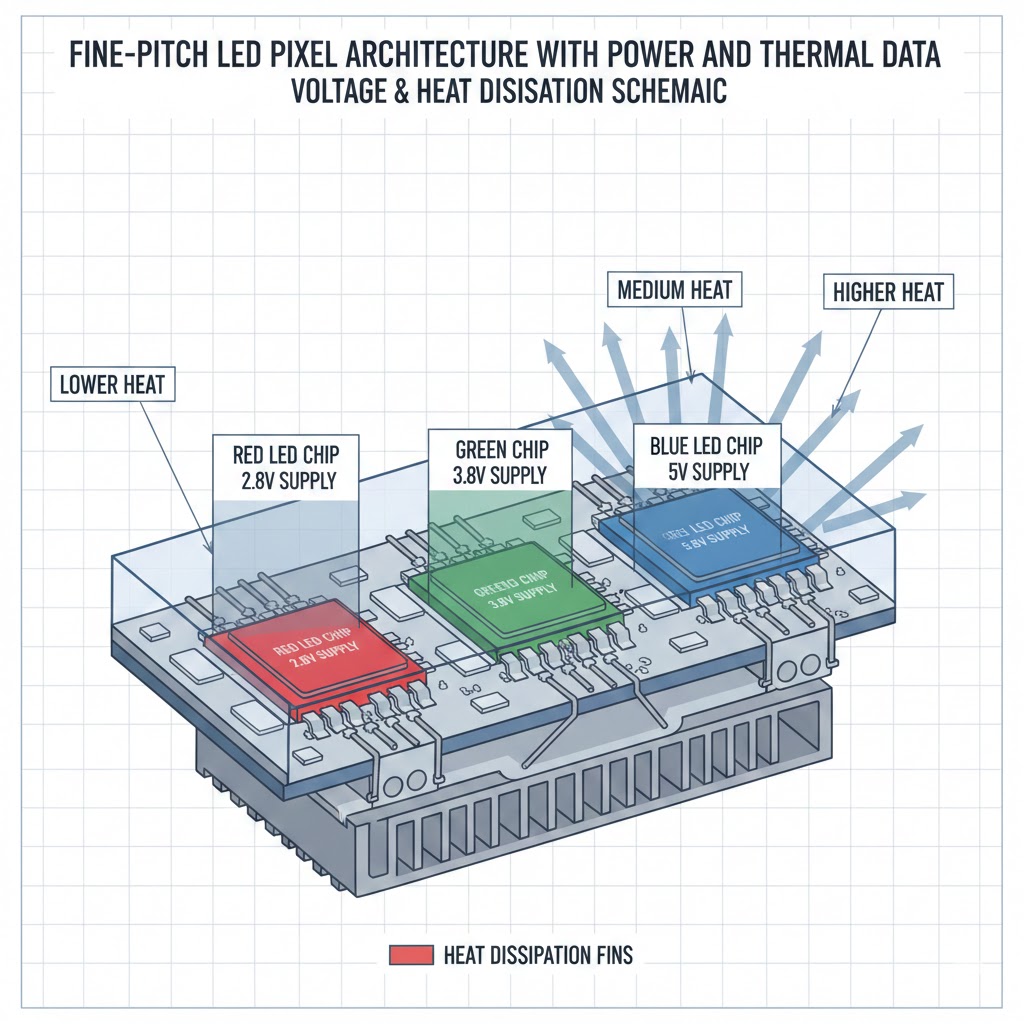

Traditional 5V power solutions have long dominated the market due to simplicity and compatibility. However, the actual forward voltage ($V_f$) of LED chips—approximately 2.0V for red and 3.0V for green/blue—is significantly lower than 5V. The voltage difference ($\Delta V$) is dissipated as heat in the driver circuitry. This not only wastes energy but also increases cabinet temperatures, directly affecting LED lifespan and display stability.

The Technical Evolution from 5V to 2.8V/3.8V

The core of low-voltage power solutions (also called “common-cathode” or “multi-voltage” technology) lies in refined power management. Instead of using a single 5V supply for all RGB chips, red and green/blue chips are supplied separately at voltages closer to their actual forward voltages: 2.8V for red and 3.8V for green/blue.

This precise power management minimizes $\Delta V$, resulting in:

-

Extreme energy savings: Redundant energy is converted to display brightness, theoretically reducing power consumption by 20–40%.

-

Minimal heat generation: Significantly lowers driver and cabinet temperatures, improving product reliability.

Comparing Performance: 2.8V, 3.8V, and 5V Power Solutions

For quick decision-making, here’s a comparison of the main power solutions in the market:

| Power Solution | Driving Voltage | Supply Mode | Typical Power Reduction (vs 5V) | Core Advantages | Potential Challenges |

|---|---|---|---|---|---|

| Traditional 5V | 5.0V | Constant voltage, common-anode | 0% (baseline) | Simple architecture, high compatibility | High heat, high power consumption, color drift |

| Multi-Voltage | 3.8V | Common-anode (channel-separated) | ~20% | Energy savings, lower temperature, clear improvement vs 5V | More complex supply paths, higher design requirements |

| Fine Multi-Voltage | 2.8V / 3.8V | Common-cathode (most refined) | 25–40% | Extreme energy efficiency, ultra-low heat, higher brightness/contrast | Very high requirements for driver chips and power supply, slightly higher cost |

Sostron Insight: For outdoor fixed installations (like the Ares series) or long-running projects, the 2.8V/3.8V common-cathode solution is the optimal choice for ultra-low energy consumption and long-term stable operation. It reflects our commitment to innovation and responsibility—delivering environmentally friendly, reliable products.

How Low-Voltage Solutions Achieve “Low Brightness, High Gray” Visuals

Users often worry that energy savings might compromise image quality. In reality, the opposite is true.

In low-voltage, low-heat environments, thermal drift—one of the main causes of long-term color deviation and brightness unevenness—is effectively suppressed.

Sostron’s Reta series for indoor high-contrast displays uses optimized low-voltage driving to achieve:

-

Stable gray-level performance: Low chip temperatures allow precise current control, ensuring detailed gray-level representation even in low-brightness environments like TV studios or conference centers.

-

Higher contrast: Reduced heat improves module reliability, enabling deeper blacks and more vivid colors for superior visual fidelity.

This technology underpins Sostron’s service to global clients, from high-end events like Qatari royal weddings to premium Japanese watch boutiques, ensuring exceptional visual experiences.

Long-Term Reliability and Maintenance Costs of Low-Voltage Solutions

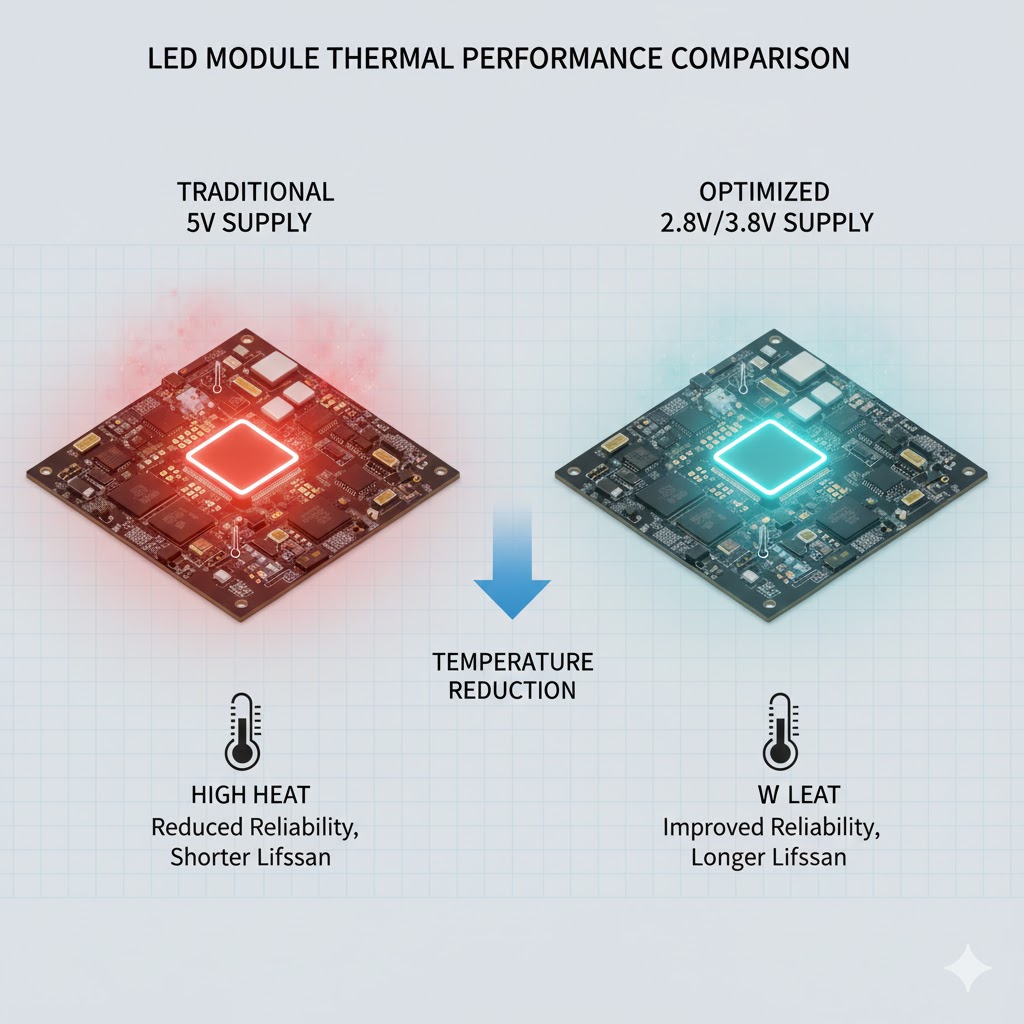

Considering total cost of ownership (TCO), low-voltage solutions provide far greater value than initial cost alone:

-

Reduced cooling and air-conditioning costs: Lower power consumption (≈30%) reduces heat output. In large outdoor projects, such as Cairo’s three-curved-surface display, it significantly cuts costs for auxiliary cooling systems.

-

Extended product lifespan: According to the Arrhenius equation, reducing temperature by 10°C roughly doubles semiconductor lifespan. Low-voltage operation creates a cooler environment, crucial for reliable operation of GOB fine-pitch displays and Ares outdoor fixed installations.

To uphold commitments to customers in over 70 countries, Sostron rigorously tests modules and cabinets with low-voltage designs, including long-term aging, waterproofing, and pressure resistance. Efficiency isn’t just speed—it’s providing turnkey digital media solutions that perform reliably on-site over the long term.

How to Choose the Right Low-Voltage Power Solution

The choice should align with your application needs:

| Application Scenario | Recommended Solution | Sostron Product | Key Reasoning |

|---|---|---|---|

| Outdoor fixed / long-term operation | Fine 2.8V / 3.8V common-cathode | Ares series | Extreme energy savings, minimal heat, optimal long-term reliability, significant operational cost reduction |

| Indoor high-definition / high contrast | Optimized 3.8V common-cathode | Reta² series | Achieves “low brightness, high gray” without compromising image quality, ideal for premium commercial displays |

| Rental / event screens | 5V or 3.8V | Hima rental screens | Prioritizes lightweight, quick setup, balancing efficiency with system compatibility |

Conclusion: Choose a Factory with Technical Expertise

In the fiercely competitive fine-pitch LED market, low-voltage power is no longer optional—it’s a benchmark for high-quality, high-reliability products. Selecting an innovative manufacturer with an experienced R&D team ensures that your low-voltage solution is market-tested and delivers real energy savings.

Sostron brings 14+ years of industry experience and a 15,000㎡ modern production facility, offering customized solutions from hardware and software to CMS systems. We control every driver chip and power path from the source, guaranteeing products that meet the highest global standards.

References:

Analog Devices (or comparable IC vendors) datasheets

About Dylan Lian

Marketing Strategic Director at Sostron