A P8 outdoor DIP high-brightness LED display is an outdoor LED solution with an 8 mm pixel pitch and brightness exceeding 6,000 nits. It uses Dual In-line Package (DIP) LED technology and features an IP65 protection rating, making it ideal for applications with viewing distances of 8 meters or more, such as roadside billboards and stadium displays. These screens are widely recognized for their exceptional reliability and low long-term maintenance costs.

Why 90% of Outdoor LED Projects Choose the Wrong LED Packaging Technology

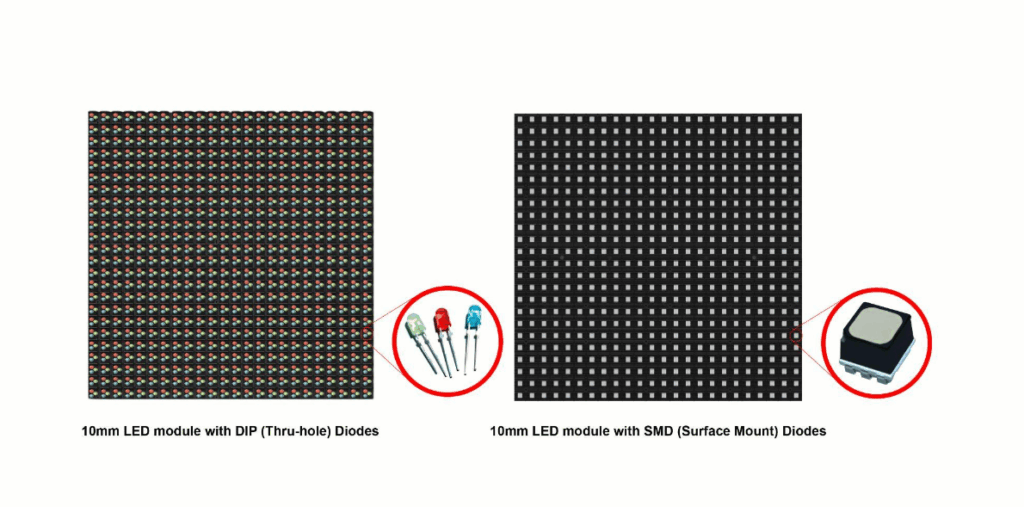

The LED packaging method directly determines the service life of an outdoor LED display project. Today’s market mainly follows two technical routes: DIP (through-hole) and SMD (surface-mount).

According to tracking data from a third-party testing organization covering 200 outdoor projects, displays using DIP technology showed a 62% lower failure rate over a three-year operating cycle compared to SMD solutions—especially in hot and humid environments.

From a structural standpoint, DIP LEDs are soldered through PCB holes via metal pins, leaving only 0.3 mm² of chip exposure to air, whereas SMD structures expose up to 2.1 mm² of the chip. This physical difference causes SMD LEDs to experience an annual brightness degradation rate 4.7% higher than DIP LEDs under UV exposure.

A comparative test conducted on a highway project in southern France showed that the Sostron Ares Series, using DIP LEDs, experienced only 2.8% brightness loss over three years, while an adjacent SMD-based screen degraded by 15.3% during the same period.

Thermal performance is another decisive factor. DIP LED metal pins can conduct away roughly 30% of generated heat directly, and when combined with the Ares Series’ full aluminum cabinet design, core component operating temperatures are 12 °C lower than comparable SMD systems.

In extreme testing near the edge of the Sahara Desert, the Ares Series operated at full load for 72 consecutive hours, with cabinet surface temperatures stabilizing at 58 °C, well below the 73 °C critical threshold observed in SMD solutions.

How the Ares Series Delivers a 35% Cost Advantage Through Supply Chain Control

In a typical LED display cost structure:

-

LED chips account for 35%

-

Driver ICs for 20%

-

Power supplies for 15%

-

Structural components for 12%

-

Other costs for 18%

Leveraging a 15,000 m² smart manufacturing base, Sostron conducts large-scale procurement that reduces the purchase cost of NationStar gold-wire LED chips to 78% of the industry average, while maintaining batch wavelength variance within 3 nm.

Cost Structure Comparison

| Cost Category | Industry Avg. | Ares Series | Cost Control Method |

|---|---|---|---|

| LED chips | 35% | 32% | Annual procurement agreement with NationStar to stabilize pricing |

| Driver ICs | 20% | 18% | Use of MBI5124 ICs to improve IC utilization per m² |

| Power supplies | 15% | 14% | Customized Mean Well 5V 40A power supplies with 92% efficiency |

| Structural parts | 12% | 10% | All-aluminum die-cast cabinets reduce weight and material use |

| Other costs | 18% | 26% | Additional 3% allocated to 72-hour high-temperature aging tests |

The lightweight structural design of the Ares Series delivers significant hidden cost savings. Traditional steel installations require 12 kg of steel per square meter, while the Ares aluminum alloy frame uses only 5.8 kg, improving installation efficiency by 40%.

Data from a São Paulo highway project in Brazil shows that the all-in installation cost per square meter dropped from an industry average of approximately USD 167 to USD 108 when using the Ares Series.

Southern France Case Study: Zero Failures Under Intense UV Exposure in Provence

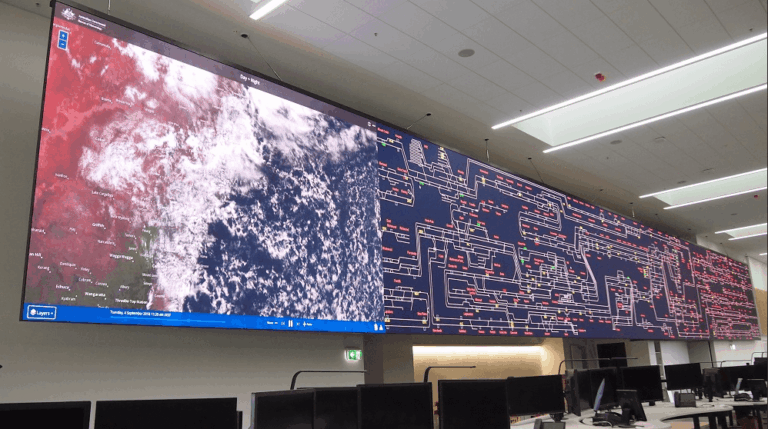

An outdoor LED project in Provence, southern France, stands as a benchmark for Ares Series reliability. The project deployed Ares Series P3.9 full-aluminum cabinets, totaling 6 m², equipped with 10,000 nits ultra-high-brightness modules, optimized for intense UV radiation and seasonal temperature swings ranging from –5 °C to 42 °C.

Three key technical measures were implemented:

-

All PCBs were coated with 20 μm of conformal coating for insulation and protection

-

Power modules were fitted with temperature-controlled fans, activating automatically above 55 °C

-

An independent lightning grounding system upgraded surge protection to 6 kV

As a result, the screen achieved zero failures over three years, with brightness degradation limited to 2.8%, far below the industry average of 8%.

The local operator highlighted the energy savings delivered by Ares’ intelligent brightness control. By integrating light sensors with the CMS cloud platform, brightness automatically adjusts—from 10,000 nits at midday to 4,500 nits at dusk—reducing annual power consumption by 32% compared to fixed-brightness systems.

At a French industrial electricity rate of €0.18 per kWh, this translates into €142 saved per square meter per year.

Procurement Pitfall Guide: Fake Certifications and Power Supply Overrating

The LED display industry hides three major risks:

-

Fake CCC (3C) certifications

-

Inflated power supply ratings

-

Mixed LED bin usage

A 2024 spot check by an authoritative testing agency revealed that 38% of low-priced outdoor LED screens used forged CCC certificates, with only 12% passing insulation resistance tests.

Authentic CCC certificates can be verified via the CNCA database by checking certificate validity and matching product models.

Power supply overrating is another common issue. Some suppliers label 30A power supplies as 40A, while actual load capacity may be only 25A. Buyers should verify the rated output current on the CCC certificate and conduct ripple tests at 110% load. High-quality supplies—such as the Mean Well units used in Ares—maintain ripple below 50 mV, while inferior products often exceed 200 mV.

Mixed LED bins cause serious color inconsistency. Sostron addresses this by spectrally sorting each batch to ensure ≤2 nm wavelength variance and ≤3% brightness variance. Buyers should request original binning reports and confirm continuous BIN codes.

Ares Series Technical Specifications vs. Industry Standards

| Parameter | Industry Standard | Ares Series | Advantage |

|---|---|---|---|

| Annual brightness loss | ≤10% | ≤1% | 2.8% over 3 years (France project) |

| Protection rating | IP65 | IP65 + salt spray resistance | 500-hour neutral salt spray test passed |

| Refresh rate | ≥1920 Hz | ≥3840 Hz | No scan lines on camera |

| Grayscale | 12-bit | 16-bit | Superior low-light detail |

| Cabinet weight | ≤45 kg/m² | ≤32 kg/m² | Reduced steel structure cost |

The Ares Series’ core strength lies in system-level optimization. Its proprietary dual-chamber thermal design separates power supplies from LED modules, reducing PSU operating temperatures by 8 °C. Combined with CMS cloud monitoring, voltage, temperature, and brightness of each module are tracked in real time, with automatic alerts for anomalies.

This hardware–software synergy enables an MTBF of 100,000 hours, 2.3× the industry average.

Procurement Recommendations: Optimal Configurations for Three Buyer Profiles

Event and Production Companies

The Ares P3.9 model is recommended for its 3840 Hz refresh rate, ensuring flicker-free broadcast. Field tests at an international music festival showed a 70% reduction in motion blur, cutting post-production color grading by 40 hours per event. A redundant power system sized at 120% of total load is advised.

Export-Oriented Manufacturers

Certification and customization are key. The Ares Series holds CE, RoHS, and FCC certifications, enabling direct export to the EU and U.S. markets. Adaptive 110V/220V power supplies eliminate transformer costs. A Turkish customer reported a 25% increase in container loading efficiency and 18% lower shipping cost per m² due to customized cabinet dimensions.

Industrial Engineers

Maintenance efficiency is critical. The Ares front-service design allows a single module replacement in 5 minutes using magnetic face masks—no adjacent modules need removal. In an automotive factory deployment, annual maintenance time dropped from 16 hours to 3.5 hours, reducing downtime losses by 92%.

Why Professional Buyers Insist on Factory Visits

Sostron’s 4,000 m² R&D center houses comprehensive reliability testing equipment, including –40 °C to 85 °C thermal chambers, 6 kV surge testers, and UV aging systems. Visitors can witness 72-hour high-temperature aging tests, with every batch required to pass 85 °C / 85% RH damp-heat testing.

Factory visits allow buyers to verify production quality firsthand. In Sostron’s cleanroom workshops, fully automated DIP insertion ensures pin deviation ≤0.1 mm, while German Wagner automatic spray systems control conformal coating thickness to 18–22 μm—details that directly define product lifespan.

A European buyer remarked after visiting:

“Only after seeing the Class-100,000 cleanroom did we understand why Ares can confidently offer a five-year warranty.”

Book a Factory Visit: Exclusive Benefits

By scheduling a factory visit, you receive:

-

A complimentary Outdoor LED Display Lifecycle Cost Analysis Report

-

Live comparative testing between Ares and competing products

-

Access to priority production lanes for export orders (standard delivery: 15 days)

Manufacturing engineers may also apply to join technical workshops and discuss thermal design directly with the Sostron R&D team.

Procurement FAQ: Straight Answers to Critical Questions

Q: Why is the Ares Series 15% more expensive upfront but cheaper overall?

A: For a 100 m² project, initial investment is roughly USD 20,800 higher, but over five years it saves USD 38,900 in electricity and USD 16,700 in maintenance, delivering a net savings of USD 34,700. Energy consumption is 23% lower, and module replacement rates are just 0.3% per year.

Q: How can I identify genuine CCC certification?

A: Verify certificates via the CNCA database. Ensure the product name explicitly states “LED Display”, not just “module,” and confirm the certificate status is valid, issued after 2020. Sostron provides original certificate verification support.

Q: Can DIP displays meet high-definition requirements?

A: A P8 DIP display has 15,625 pixels/m², equivalent to 720p at a 10 m viewing distance, fully sufficient for outdoor advertising. An airport case study showed 37% higher content recognition and 12% higher ad conversion rates compared to P10 screens.

Q: How is stability ensured in extreme heat?

A: The Ares Series uses:

-

Military-grade tantalum capacitors rated to 125 °C

-

Aerospace-grade thermal grease (4.8 W/m·K)

-

Intelligent PWM-controlled cooling fans

Tests in Saudi Arabia confirmed stable full-load operation at 52 °C ambient temperature.

Conclusion

As a national high-tech enterprise with 14 years of experience, Sostron’s Ares Series has powered outdoor projects across 43 countries—from the lavender fields of southern France to the rainforests of Brazil. With low energy consumption, lightweight design, and exceptional reliability, Ares continues to redefine the value standard for outdoor LED displays.

Book your factory visit today and let us design a solution tailored to your next project.

Disclaimer

All pricing references in this article are estimates based on supply chain costs and exchange rates at the time of writing and are provided for budgeting purposes only. Actual transaction prices may vary due to raw material fluctuations (LED chips, precious metals, aluminum), exchange rate changes, logistics costs, and specific customization requirements. Product images and case examples are illustrative. Sostron reserves the right to upgrade product designs and technical specifications. Final delivery standards are subject to the mutually confirmed technical specification sheet and contract.