Table of Contents

ToggleDefinition and Core Value

A 100-inch LED conference display is an indoor visual system with a diagonal ≥ 2.54 meters, typically using COB (Chip-On-Board) or SMD (Surface-Mount Device) packaging technology. It delivers high gray-level performance at lower brightness, seamless splicing, and is suitable for medium to large conference rooms. Compared to traditional projectors, it can reduce long-term operational costs by up to 40%.

Key features include high brightness, rich color saturation, wide viewing angles, and a long lifespan of 50,000 hours with slow degradation. High-density LED pixel modules enable HD display of text, images, and video, while supporting intelligent interaction and multi-device collaboration. The display evolves from a mere “visual terminal” to the “visual soul” of the meeting space.

From a technical standpoint, Sostron, a national-level high-tech enterprise, brings 14 years of industry experience, a 15,000㎡ intelligent manufacturing base, and a 4,000㎡ R&D center, offering proven reliability and scalable production.

By creating modern, digitalized conference environments, facilitating remote collaboration, and enhancing content presentation, these LED displays significantly improve communication efficiency and participant engagement, making them a cornerstone of corporate digital transformation.

Core Technical Parameters and Solution Comparison

Pixel Pitch Selection Guide

Pixel pitch—the distance between adjacent pixels (in millimeters)—is a core determinant of display clarity and cost. Smaller pitches offer higher image quality but increase expenses. For example, P1.8 panels cost about 15% more than P2.5, while delivering only an 8% image quality improvement. Hidden costs should be considered.

Selection should match the room size:

-

30–50㎡: P2.0 (250,000 pixels/㎡, minimum viewing distance 2m)

-

50㎡: P2.5, balancing performance and economy

The Sostron Reta2 series offers both P2.0 and P2.5 models for mainstream conference scenarios.

Quick selection rule:

-

Ultra-fine pitch (P1.8 or below): boardroom 3–5 meters

-

Medium pitch (P1.8–P2.5): medium to large conference rooms 6–10 meters

-

P2.0/P2.5: best cost-performance choice

Packaging Technology Trends

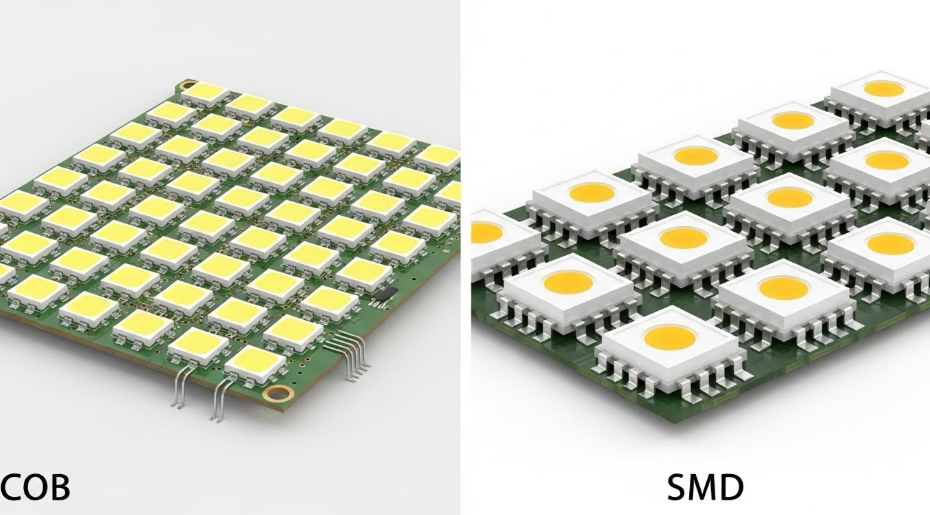

LED packaging technology directly impacts display performance and applicable scenarios. COB technology is emerging as a preferred solution in conference displays due to its low-brightness, high-gray performance. 16-bit gray levels provide smoother color transitions and richer image detail, critical for video conferencing, avoiding distortion or detail loss in low-light settings.

Industry warning: TÜV Rheinland reports that 63% of products claiming 16-bit gray levels fail to meet standards. Buyers should verify chip authenticity and quality. Sostron uses Epistar chips to ensure true 16-bit gray performance and reliable product operation.

COB offers high reliability, superior protective features, narrow pixel pitch, and excellent image quality. It eliminates the “grainy” look typical of standard SMD LEDs, making it widely adopted in professional conference environments.

Commercial Value and Cost Management

Supply Chain Cost Breakdown

From a supply chain perspective, the cost of a 100-inch P2.5 LED conference display requires deep BOM (Bill of Materials) analysis:

-

Core panel modules: ~42%

-

Driver ICs: ~18%

-

LED beads and PCB boards constitute the primary module cost

Chip selection affects cost significantly. Taiwanese Epistar chips are 15–20% more expensive than domestic alternatives like Silan. Power management, thermal design, and other components also account for substantial costs.

Scale production is key to cost efficiency. Sostron’s 15,000㎡ intelligent manufacturing base leverages centralized procurement and automated lines to reduce comprehensive costs by ~12% compared to smaller factories. Cost advantages extend across LED beads, driver ICs, and installation/commissioning (installation accounts for ~15%).

Cost control recommendation: prioritize vendors with scalable production, verify BOM completeness, and avoid hidden post-installation costs. Sostron offers real-time BOM analysis and quotes for precise cost planning.

Long-Term Maintenance Cost Optimization

Preventive maintenance is essential, including quarterly static electricity tests, annual pixel calibration, environmental control (humidity ≤60%, temperature -40℃ to 60℃), and monthly dust removal (without alcohol-based cleaners).

Sostron’s modular thermal redundancy design reduces maintenance frequency by 30%. Nanocoated LED beads show only 3–5% brightness decay over 18 months (vs. 12–15% for standard products), resulting in 5-year maintenance costs around $1,200—significantly below the industry average of $2,500.

Key cost control points:

-

ESD protection: dry areas should meet ≥8kV, reducing dead-pixel rate by 8–12% annually

-

Warranty: prioritize 3-year screen warranty + 48-hour on-site service

-

Operation strategy: avoid 24/7 usage; recommended 8 hours on, 30 minutes off

-

Environmental factors: dust and high humidity accelerate heat dissipation failures and component corrosion

Beware exaggerated “50,000-hour lifespan” claims. Focus on actual brightness decay curves and ESD protection metrics.

Industry Pitfalls and Standards Comparison

Authenticity Verification

LED displays often suffer from inflated specs. TÜV Rheinland’s “LED Display Parameter Verification Standard” shows only 63% of claimed 16-bit gray displays are genuine. Verification should include:

Technical testing:

-

Refresh rate: 240fps camera test; no scanning lines confirm true 3840Hz

-

Gray level: 16-level grayscale test at low brightness; no banding confirms 16-bit

Company credentials: check for national high-tech enterprise status to ensure ongoing R&D capacity.

Component tracing: verify chip authenticity; counterfeit chips cause blurry images, color distortion, and high failure rates. Sostron provides chip traceability reports for verification of model and batch.

Physical resolution check: confirm that “100-inch 4K” products are true 3840×2160 resolution, not just 1920×1080.

Contract and After-Sales Risk Management

For cost transparency, review contracts for:

-

Maintenance coverage

-

LED bead replacement fees

-

Response time guarantees

Prefer vendors offering 3-hour fault response and 48-hour on-site service. Inspect warranty terms and payment arrangements carefully.

Small vendors often lack timely after-sales support and spare parts supply. Visiting factories to verify production scale, quality control, and service processes is recommended.

Choosing brands with on-site installation and remote diagnostics reduces long-term operational costs.

Sostron Solutions and Case Validation

Sostron’s Reta2 series leverages 14 years of LED experience. Features include:

-

COB eutectic soldering

-

Epistar chips with 16-bit gray levels

-

5000:1 high contrast and ≤3% black screen non-uniformity (industry standard SJ/T11141-2025 ≤5%)

-

P2.0 for 30–50㎡, P2.5 for larger rooms

-

Scale production reduces cost ~12% vs. smaller vendors

Technical advantages:

-

Display: 5000:1 contrast + low-bright/high-gray for clear details

-

Reliability: eutectic soldering improves impact resistance

-

Scenario adaptability: P2.0/P2.5 models match room sizes

In a Mexican indoor P2.5 project, Sostron displays ran 6 months without failure, demonstrating stability and durability. Customizable solutions meet diverse conference needs.

[Click here for custom solutions]

FAQ

Why is Sostron ~20% more expensive than small factories?

-

Core components (SMD2121 chips) cost 15% more, but scale production lowers unit cost 12%. Overall effective cost difference ~3%, while brightness uniformity and color consistency improve >20%.

How to match pixel pitch to room size?

-

Viewing distance/1000 rule:

-

<8㎡: P1.2–P1.5

-

15–30㎡: P1.8–P2.5

-

50㎡: P2.5–P3.9

-

-

Example: 20㎡ room with 100-inch display → P2.0 optimal

5-year maintenance cost?

-

LED display: 3–5% of purchase price/year

-

Example P2.0: ~$1,200–$2,000 for LED replacements, power module maintenance, software updates

-

Products with proactive maintenance reduce labor costs 40%

Pros and cons of packaging technologies:

-

SMD: wide viewing angles, good color uniformity; weaker impact resistance, higher cost

-

COB: high integration, IP65, robust; requires full module replacement for repair, higher maintenance cost

-

IMD: combines SMD visual performance and COB reliability; emerging tech

Product lifespan:

-

LED life: 50% brightness decay ~100,000 hours

-

Daily 8 hours, 260 days/year → ~48 years

-

Power supplies/driver ICs: 5–8 years; modular replacement recommended

Procurement tip: contracts should specify core component brand/model, brightness decay guarantee (e.g., ≥90% in 3 years), and after-sales response (≤4 hours, on-site within 24 hours).

Decision-Making Guide

Use a “Technology + Cost + After-Sales” model:

-

Technology: pixel pitch, COB packaging (P2.0 for 30–50㎡, P2.5 for larger)

-

Cost: initial + maintenance

-

After-Sales: clear response times

Visit factories before ordering to verify production capacity and quality control (e.g., Sostron 15,000㎡ base, ISO9001-certified). This ensures informed and scientifically sound purchasing decisions.

Disclaimer

All price references are estimates based on current supply chain costs and exchange rates, for budgeting purposes only. Actual prices may vary due to raw material fluctuations (LED chips, precious metals, aluminum), exchange rates, logistics, and customization requirements. Images and cases are for reference; Sostron reserves the right to upgrade product appearance and technical specifications. Final delivery standards shall follow mutually confirmed technical specifications and contracts.

References:

VESA (Video Electronics Standards Association)

Reliability and “true 16‑bit grayscale” validation

About Dylan Lian

Marketing Strategic Director at Sostron