Table of Contents

ToggleExecutive Summary

-

Why immersive experiences depend on custom-shaped LED design

-

Flexible modules vs. die-cast aluminum vs. carbon-fiber structures

-

Application scenarios and physical limits of irregular LED displays

-

Hidden supply-chain costs and long-term value analysis

-

Three “unwritten rules” of non-standard LED customization, revealed by experts

-

In-depth answers on pricing, maintenance, and thermal management

-

The Sostron advantage: how 14 years of experience powers world-class stages

Quick Overview

Custom-shaped stage LED displays break away from conventional rectangular formats by using flexible LED modules, die-cast aluminum cabinets, and non-standard splicing techniques to create cylindrical, curved, spherical, ribbon-like, and other creative structures.

At the core of this technology is the integration of P1.9–P3.9 high-density pixel pitch with advanced 3D visual algorithms. Supported by precision manufacturing in a 160,000 sq. ft. (15,000 m²) smart production facility, these systems solve key challenges such as heat dissipation, surface flatness, and signal synchronization in non-standard structures. As a result, custom-shaped LED displays have become a primary visual asset for boosting the premium value of stage and performance projects.

The Evolution of Stage Aesthetics: Why “Custom Shapes” Are the Only Way Forward

In today’s live entertainment and exhibition markets, standard rectangular LED walls have been reduced to mere backgrounds. Custom-shaped LED displays, by contrast, are the visual centerpiece.

Spatial Integration

Custom-shaped displays blend seamlessly with architectural elements such as concert hall columns or theater domes, eliminating the visual disconnect between digital equipment and physical space.

Immersive Experience

When paired with glasses-free 3D content, curved display surfaces provide a wider field of view than flat screens, creating a true “wrap-around” visual effect.

A Real Pain Point for Rental Companies

Curves assembled from traditional rental cabinets often show visible gaps or black lines. These flaws are immediately exposed during close-up filming, directly harming production quality and brand reputation.

Deep Technical Breakdown: How Is “Seamless” Custom Splicing Achieved?

Custom-shaped LED displays are not about cutting cabinets into odd shapes. They require a fundamental redesign of materials science and signal engineering.

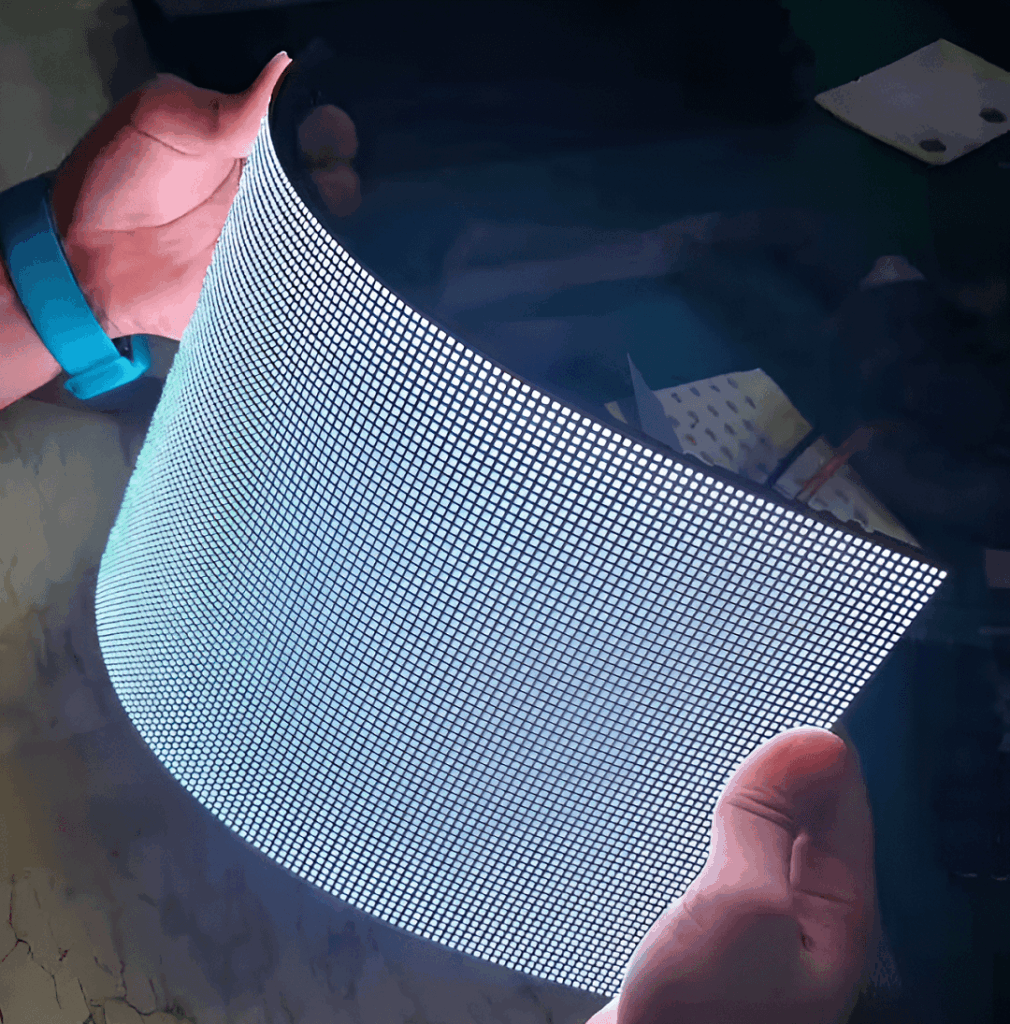

Flexible LED Modules and the True 360° Physical Limit

True custom shaping relies on silicone-based flexible LED modules. Unlike rigid PCBs, flexible PCBs must maintain circuit integrity during bending.

Through copper-layer optimization, Sostron’s R&D team has achieved cylindrical displays with a minimum diameter of just 200 mm, without compromising signal stability or image quality.

Signal Redundancy and Distributed Processing

Because custom-shaped displays use non-linear pixel mapping, standard controllers often cause image distortion. Sostron applies advanced pixel-mapping and distributed processing technology to ensure that every pixel is rendered at a precise 1:1 ratio—whether on spherical, curved, or ribbon-style structures.

Table 1: In-Depth Comparison of Mainstream Custom-Shaped LED Technologies

| Dimension | Flexible Module Solution | Curved Die-Cast Cabinets (e.g., Hima Series) | Carbon-Fiber Lightweight Solution (Carbon Series) |

|---|---|---|---|

| Physical Form | 360° free bending, spheres, S-curves | Adjustable from −15° to +15° | Large suspended structures, rapid assembly |

| Installation | Magnetic mounting / custom steel frames | Quick-lock cabinet system | Modular hanging system |

| Protection Rating | Indoor IP30 | IP65 (indoor & outdoor) | IP65 (high-intensity rental use) |

| Ideal Applications | Creative showrooms, indoor columns | Music festivals, circular backdrops | Large tours, arenas, overhead rigs |

| Core Advantage | Maximum flexibility | Balance of stability and speed | Ultra-lightweight design reduces motor load |

Commercial Value and Hidden Supply-Chain Costs

Many B2B buyers focus on unit price while overlooking total cost of ownership (TCO).

The Maintenance Trap of Non-Standard Components

Some manufacturers complete a custom project without a spare-parts system. Two years later, when a module fails, clients discover the original PCB batch is no longer available.

With 14 years of experience, Sostron assigns a unique project ID to every custom display, ensuring spare-part consistency for at least five years.

Power Consumption and Thermal Management

Custom-shaped displays are often installed in decorative structures with poor airflow. Sostron’s ColdLED technology separates the driver IC from the LED chip, reducing operating temperature by 27°F (15°C) and extending lifespan by approximately 30%.

Table 2: ROI Comparison — Standard LED vs. Sostron Custom-Shaped LED

| Metric | Standard LED Display | Sostron Custom-Shaped LED | Business Impact |

|---|---|---|---|

| Initial Audience Attraction | Average | Very strong (organic social traffic) | Typically 3× longer dwell time |

| Annual Maintenance Cost | ~10% (structural stress) | ~3% (precision die-cast design) | Lower long-term operating costs |

| Energy Efficiency | Standard | ~30% lower consumption (Ares / Reta2 architecture) | Ideal for large fixed installations |

How to Avoid Costly Mistakes

Before signing any contract, experienced professionals recommend checking the following three points:

-

Reject Plastic Back Covers

Custom modules must use high-grade silicone or aluminum. Plastic warps under thermal expansion and contraction, causing visible surface distortion. -

Demand Full Pre-Assembly Proof

Request full-scale pre-assembly videos from the manufacturer’s production facility. Without factory pre-assembly, on-site installation success is essentially zero. -

High Refresh Rate at Low Brightness

Stage filming hates artifacts. Require a refresh rate ≥ 3840 Hz. At 20% brightness in dark scenes, grayscale performance should remain smooth—this is the true test of professional-grade displays.

FAQ: Straight Answers to Tough Questions

Q: How much more expensive are custom-shaped LED displays?

A: Module costs are typically 30–50% higher than standard panels. The real difference lies in custom steel structures and signal-mapping calibration. For high-quality projects, this premium is often recovered within 12 months through higher rental or advertising revenue.

Q: Is maintenance more difficult?

A: No. Sostron solutions such as the Reta2 Series support full front access service. Using a vacuum tool, one technician can replace a module in about 10 seconds.

Q: How is heat managed in complex structures?

A: Sostron uses a proprietary aluminum thermal framework combined with a cloud-based CMS warning system to monitor temperature and current in real time at the module level.

The Sostron Solution: From CAD Design to Final Power-On

We don’t just sell LED screens—we deliver a complete execution system.

-

43,000 sq. ft. (4,000 m²) R&D Center

Solves structural engineering challenges and provides full 1:1 construction drawings. -

Ares & Carbon Series Platforms

Proven hardware foundations for different environments. In a Chilean music festival project, Carbon Series carbon-fiber displays achieved zero-failure delivery under strong winds and high-altitude suspended installation. -

National High-Tech Enterprise Certification

Backed by 14 years of engineering expertise, every project is reviewed by senior specialists.

Want your stage to stand out—not blend in?

Get the 2025 Custom-Shaped LED Display Price List or schedule a visit to Sostron’s 160,000 sq. ft. smart manufacturing facility to test our high-refresh display performance in person.

Classic engineering principles still matter—but smart innovation is what wins the spotlight.

References:

IES RP-49 – IES Light Measurement Standards

About Dylan Lian

Marketing Strategic Director at Sostron