Table of Contents

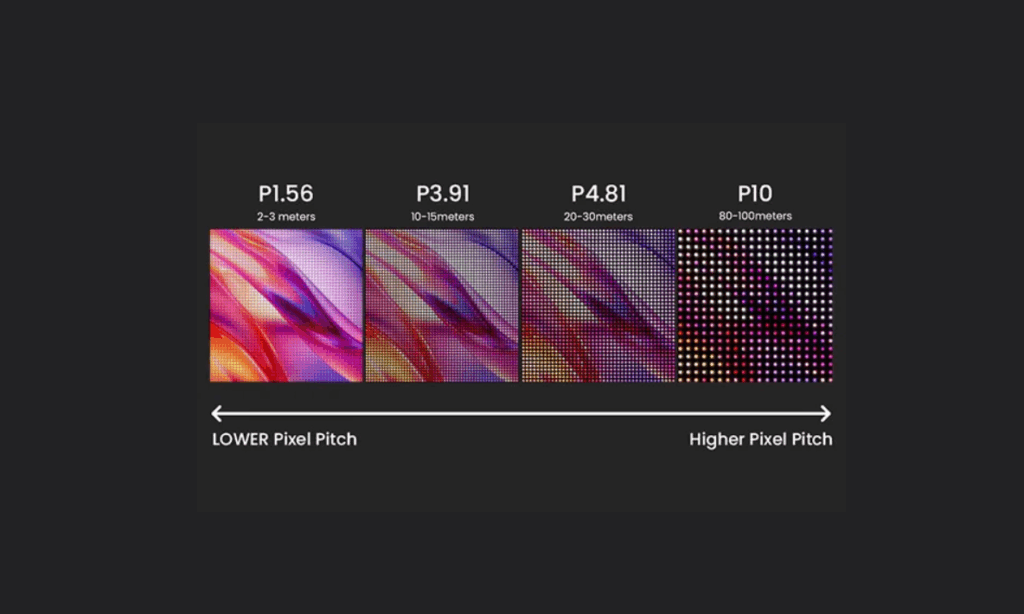

ToggleThe P1.56 LED video wall is a fine-pixel-pitch display solution engineered specifically for close viewing distances between 1.5 and 5 meters. Its core advantage lies in a 1.5625 mm pixel pitch combined with a 600 × 337.5 mm cabinet in a native 16:9 ratio, allowing true 1:1 physical pixel mapping to standard Full HD (1920×1080) or 4K (3840×2160) resolutions—without relying on complex scaling from external video processors.

This architecture strikes a rare balance between retina-level image clarity and project budget discipline, making P1.56 the go-to standard for high-end conference rooms, broadcast studios, and security control centers.

Why Is P1.5625 mm Considered the “Gold Standard” in 2025?

Over the past 14 years, I’ve watched the LED industry race from P3 down to P0.9, often driven more by competition than by real-world needs. As a former supply chain director responsible for nine-figure procurement budgets, I’ll state an uncomfortable truth for production companies and system integrators:

The most expensive option (P0.9 / P1.2) is rarely the most suitable one. The right choice always beats the extreme choice.

The real purchasing driver behind P1.56 is its ability to resolve the tension between “resolution anxiety” and budget constraints.

The Victory of Physical Resolution

Many buyers choose P1.667 or P1.8, only to discover distortion or black borders when displaying standard 1080p presentations or 4K video. P1.5625 mm avoids this entirely due to its precise mathematical alignment:

-

Single cabinet resolution: 384 × 216 pixels

-

5 × 5 cabinets: 1920 × 1080 (Full HD)

-

10 × 10 cabinets: 3840 × 2160 (4K)

For broadcast-grade users demanding zero distortion, P1.56 is effectively the only specification that enables true pixel-to-pixel display without forcing expensive scaling through high-end video processors.

Technical Deep Dive: The “Invisible Parameters” That Define Image Quality and Lifespan

On paper, most spec sheets look identical—3840 Hz, 16-bit, 800 nits. At Sostron’s 4,000 m² R&D center, we break these numbers down into three make-or-break dimensions.

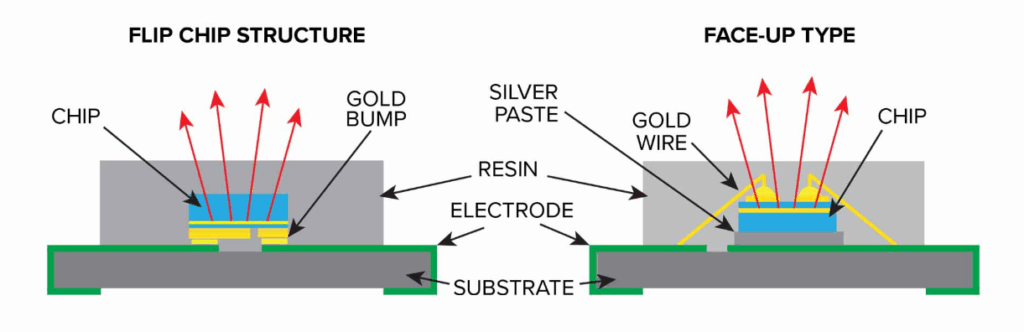

2.1 LED Package & Wire Bonding: Gold Wire vs. Copper Wire

For B2B buyers, the biggest risk isn’t price—it’s the dead pixel rate.

Over 90% of low-cost P1.56 displays on the market use copper-lead LED packages. Copper oxidizes easily in humid environments—even in air-conditioned rooms with condensation—leading to “caterpillar effects” or blind pixels after 6–12 months.

Sostron standard:

In our Reta 2 indoor fixed-install series, we mandate Nationstar gold-wire LEDs or Kinglight premium lines. Gold’s superior ductility and oxidation resistance form the physical foundation for five years of stable, failure-free operation.

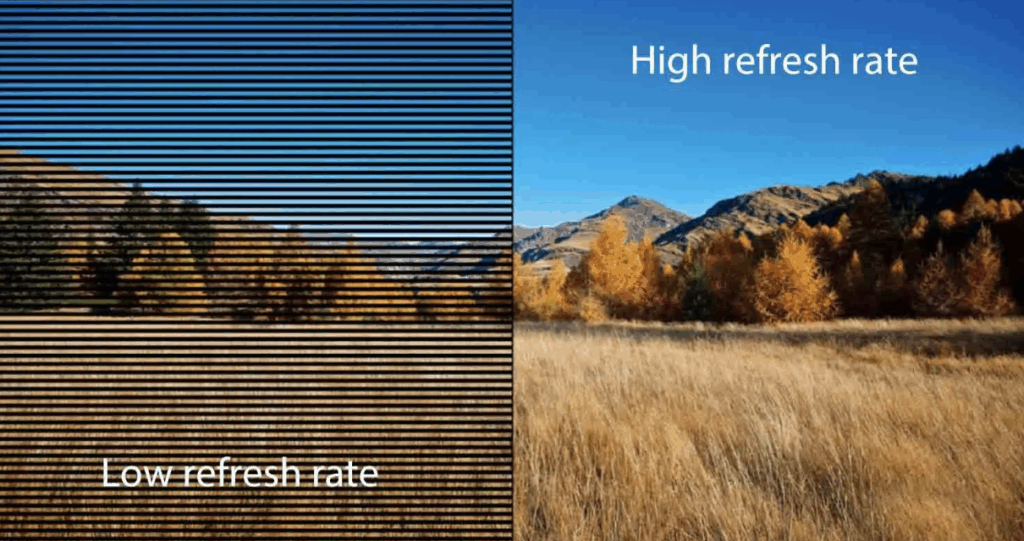

2.2 Driver ICs & Refresh Rate: Saying No to “Inflated Specs”

If your application involves camera capture—broadcast studios, XR stages, or live streaming—this is critical.

Many suppliers force generic PWM driver ICs to claim 3840 Hz refresh rates, resulting in:

-

Low-gray banding: color block artifacts below 30% brightness

-

Scan lines & flicker: black ripples visible on smartphones or professional cameras

Our solution:

We use Macroblock MBI5153 or Chipone ICN2153 high-end drivers, paired with NovaStar receiving cards, ensuring 14–16-bit grayscale performance even at low brightness, completely eliminating moiré and flicker.

Decision Anchor: Should You Choose P1.25 or P1.56?

To support engineering-level decision-making, here’s a practical comparison based on visual experience and total cost:

Table 1: Pixel Pitch Selection Matrix

| Core Metric | P1.25 (Ultra-HD) | P1.56 (Golden Balance) | P1.875 (Economy) |

|---|---|---|---|

| Optimal Viewing Distance | > 1.2 m | > 1.6 m | > 2.0 m |

| Cabinet Resolution | 480 × 270 px | 384 × 216 px | 320 × 180 px |

| Cost Index | High ($$$) | Medium ($$) | Low ($) |

| Maintenance Difficulty | Very High (microscope-level) | High (professional tools) | Moderate |

| Typical Applications | Command centers, boardrooms | Studios, large conference halls | Retail lobbies, hotels |

| Recommended Series | Sostron Reta 2 | Sostron Reta 2 / Storm Plus | Sostron Storm |

Product Spotlight: Sostron Reta 2 Series

For projects where aesthetics matter, Reta 2 is the ideal carrier for P1.56. It features:

-

Full die-cast aluminum construction

-

Ultra-slim 30 mm depth

-

True cable-free design

By eliminating internal ribbon cables, Reta 2 removes one of the most common failure points—loose connections—making it ideal for executive meeting rooms and luxury retail environments.

Supply Chain Reality: Where Your Money Actually Goes

With a 15,000 m² smart manufacturing facility, we understand the real cost of “cheap.” Supply chains aren’t just about assembly—they’re about risk control.

3.1 The Hidden “Binning Risk”

LED production naturally creates variations in wavelength (color) and brightness (BIN codes).

-

Low-cost practice: mixing LED bins from different batches

-

Looks fine on day one

-

After ~3,000 hours, uneven degradation turns the screen into a “patchwork”

-

-

Sostron practice:

-

Single-BIN documentation per project

-

3–5% same-batch spare modules reserved

-

This ensures that even three years later, replacement modules match perfectly in color and brightness.

Real ROI: Buying Cheap vs. Operating Cheap

Many procurement teams focus only on CAPEX, ignoring OPEX.

Table 2: 5-Year Total Cost of Ownership (TCO)

| Cost Component | Generic Assembly Screen | Sostron Custom Solution | Expert Insight |

|---|---|---|---|

| Initial Purchase | $10,000 | $12,500 | Premium materials & patented design |

| Annual Maintenance / Downtime | $4,500 | $500 | Cheap power & poor cooling fail often |

| Energy Cost (5 years) | 100% | 70% | 30% savings via common-cathode ICs |

| 5-Year Total | $14,500 + risk | $13,000 + reputation | Sostron costs less long-term |

Pitfall Guide: Straight Talk for Engineers and Executives

Before signing any contract, watch for these three hidden traps:

-

“Easy maintenance” myths

P1.56 SMD LEDs are microscopic. Anyone claiming “hand replacement on site” is lying.

Solution: vacuum maintenance tools or GOB (Glue-on-Board) protection for impact, moisture, and dust resistance. -

Insufficient power margin

Many suppliers run power supplies at >90% load. Long term, that’s a failure recipe.

Sostron standard: 20% power redundancy, operating at the 70–80% efficiency sweet spot. -

Inadequate aging tests

Industry norm: 24 hours. This misses early component failures.

Our standard: 72-hour aging with video, white balance, and thermal cycling.

Proven in the Field: Mexico Indoor Display Project

In a Mexican indoor P2.5 commercial project, the client faced extreme grid voltage instability. By deploying wide-voltage power supplies and enhanced thermal design, Sostron ensured 24/7 stable operation under unstable conditions.

That same engineering logic is now embedded in our P1.56 designs.

The Sostron Solution: We Don’t Just Sell Screens—We Deliver Certainty

When you choose Sostron, you’re not buying LED modules—you’re buying 14 years of manufacturing certainty.

Table 3: Quality Control Comparison

| Test Item | Industry Standard | Sostron Smart Manufacturing |

|---|---|---|

| Aging Test | 24 hours (power-on only) | 72 hours (video, WB, thermal shock) |

| Moisture Testing | Random sampling | 100% high-pressure spray testing |

| Vibration Test | None | Simulated land & air transport |

| Warranty | 2 years (parts only) | 3–5 years + lifetime technical support |

Frequently Asked Questions (FAQ)

Q: Is P1.56 suitable for XR virtual production?

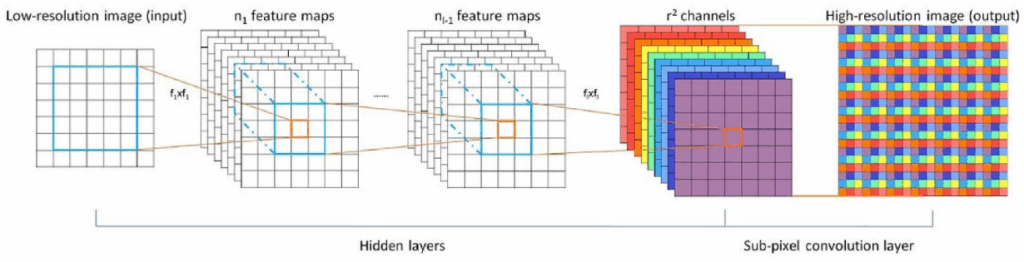

A: Yes—but only with the right configuration. Standard P1.56 is not sufficient. You’ll need Brompton or NovaStar COEX control systems and 7680 Hz-capable driver ICs. For professional XR, we recommend our Hima Series, purpose-built for virtual production.

Q: Why are your prices higher than some Alibaba suppliers?

A: This is about value, not price. Many Alibaba sellers are traders who cannot control LED batches. As a source factory, our pricing includes Grade-A Nationstar gold-wire LEDs, 72-hour aging, and 5% batch-matched spares. We sell insurance against black screens during critical events.

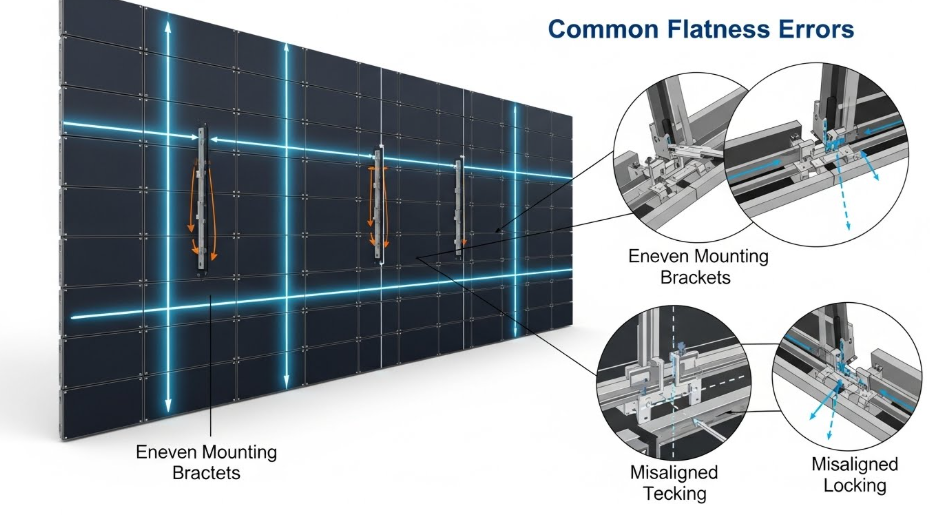

Q: Does P1.56 require special steel structures?

A: Yes—precision matters. A 0.5 mm structural error can cause visible bright or dark seams. Sostron provides die-cast aluminum mounting frames with six-axis (X/Y/Z) micro-adjustment, ensuring seam flatness < 0.1 mm.

Next Step

In the LED industry, photos can be retouched and specs can be exaggerated—but factory production lines don’t lie.

If you’re planning a high-definition video wall project, or you’re simply tired of after-sales nightmares from low-end products:

👉 Request a P1.56 Engineering Quotation

Includes a detailed spare-parts list and logistics cost estimation.

References:

Display Refresh Rate & Flicker Elimination Guidelines

About Dylan Lian

Marketing Strategic Director at Sostron