Table of Contents

ToggleThe price of P2.5 indoor LED modules is primarily driven by four key variables: LED package type (gold wire vs. copper wire), driver IC refresh rate (1920Hz vs. 3840Hz), PCB layer count, and batch consistency. In 2025, the factory unit price for a standard P2.5 module ranges between $XX – $XX, while the total cost for a complete display—including the control system and die-cast aluminum cabinet—varies depending on configuration. Buyers should not focus solely on the quoted price; the dead-pixel rate and color degradation after 14,000 hours of operation are far more critical metrics.

The “Black Box” Behind Pricing: Why P2.5 Quotes Vary So Much

As a display industry engineer with 20 years of hands-on experience, the question I hear most often is: “Why is Company A’s P2.5 module 40% cheaper than Company B’s?” In the LED industry, a low price often signals material downgrades rather than operational efficiency.

1. LED Package: Gold Wire vs. Copper Wire

This is the largest cost differentiator for P2.5 modules.

-

Gold Wire: Excellent conductivity, thermal stability, and oxidation resistance. Gold wire modules maintain a dead-pixel rate below 0.0001%, even under high-heat conditions.

-

Copper Wire: Costs only half as much as gold wire, but is highly prone to oxidation. In coastal or humid regions, copper wire modules can see an exponential rise in dead pixels after 12-18 months of use.

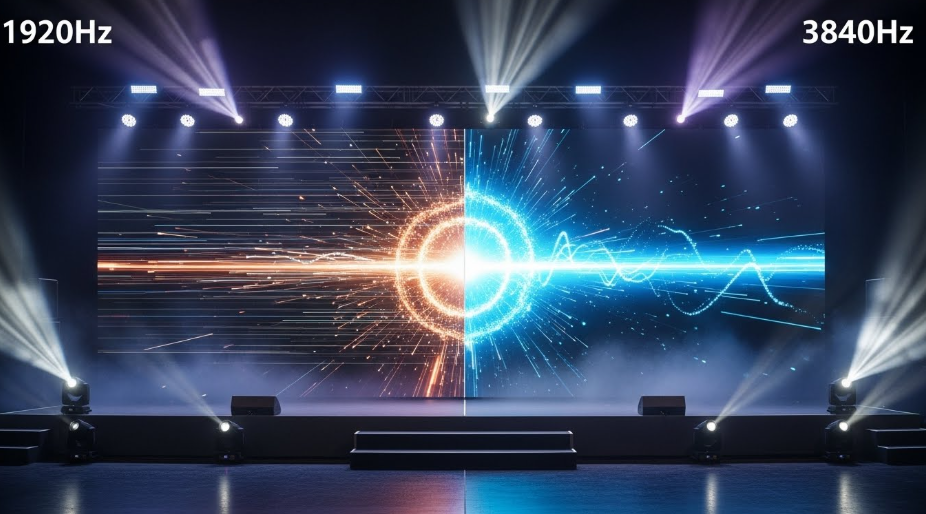

2. Driver IC and Refresh Rate: The “Visual Accounting”

For entertainment or performance venues, low refresh rates are a critical risk.

-

1920Hz: Appears fine to the naked eye, but when recorded with a phone or professional camera, noticeable black bars (scan lines) appear.

-

3840Hz / 7680Hz: High-end chips like ICN2153 or MBI5124 are used. This ensures superior grayscale performance, keeping images smooth and detailed even at low brightness levels.

3. PCB Material: The Hidden Support

Low-cost modules often use 1.0mm single- or double-layer PCBs, while Sostron’s standard is 1.6mm 4-layer FR4. Thicker boards prevent physical deformation caused by heat, ensuring the assembled display looks like a seamless “mirror” rather than a “corrugated surface.”

| Configuration Dimension | Economy (Retail) | Professional (Rental/Studio) | Flagship (Sostron Reta 2) |

|---|---|---|---|

| Package Material | Copper Wire | Gold Wire | Tier 1 Gold Wire |

| Refresh Rate | 1920Hz | 3840Hz | 3840Hz – 7680Hz |

| Driver IC | ICN2037 / Generic | ICN2038S / MBI5124 | ICN2153 / High-end Custom |

| PCB Thickness | 1.0mm – 1.2mm | 1.6mm | 1.6mm (4-layer) |

| Flatness Tolerance | <0.5mm | <0.2mm | <0.1mm (CNC Die-cast) |

| Expected Lifespan | 3 – 5 years | 5 – 8 years | 8 – 10 years |

Hidden Supply Chain Costs: Saving Now vs. Losing Later

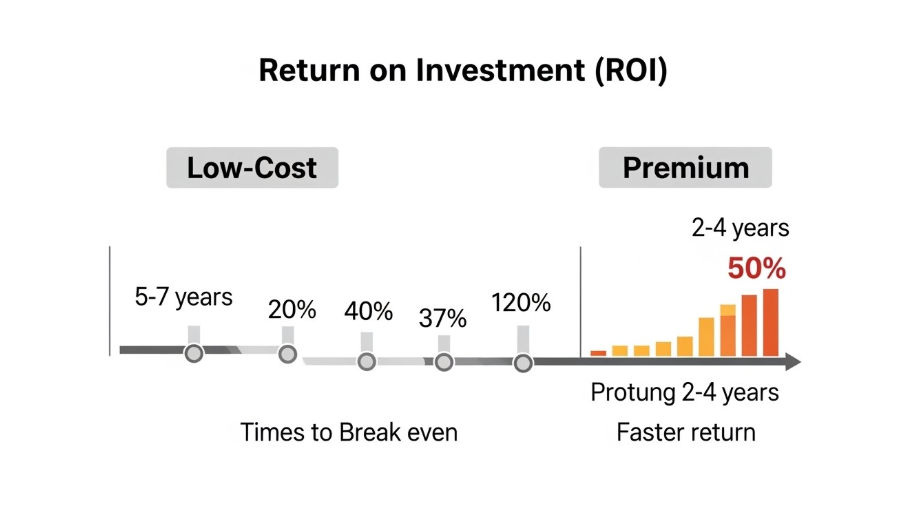

For factory owners and engineers in manufacturing, Total Cost of Ownership (TCO) is more insightful than the purchase price alone.

1. Batch Consistency Issues

LEDs are semiconductors, and LEDs from different batches have color temperature variations. Splitting purchases across batches can result in visible color mismatches. Sostron’s 15,000㎡ smart factory ensures large orders are supplied under a single BIN number, keeping full-screen color consistency nearly perfect.

2. Energy Consumption

Traditional P2.5 modules often use common-anode power, converting significant energy into heat. Our energy-efficient series uses precise voltage distribution to reduce power consumption by 30%-50%.

Example: A 100㎡ P2.5 indoor display running 12 hours per day can save $2,500 – $4,000 annually using our energy-saving solution.

| Cost Item | Low-cost Version | Sostron Premium Version | Difference Analysis |

|---|---|---|---|

| Initial Purchase | $10,000 | $14,000 | Premium costs 40% more |

| 3-Year Maintenance | $3,500 (frequent module replacements) | $300 (minimal service) | Low-cost has high after-sales costs |

| 3-Year Electricity | $12,000 | $7,500 | Energy-efficient chips save 38% |

| Brand/Image Loss | Significant (color shift/dead pixels) | None | Intangible benefit |

| Total Expenditure | $25,500 | $21,800 | Premium actually saves $3,700 |

Buyer’s Guide: Spotting Supplier “Buzzwords”

When evaluating suppliers, be sure to ask these three sharp questions:

-

“Can you provide PCB copper thickness documentation for this batch?”

-

If vague, the supplier likely uses thin boards.

-

-

“How do you handle dead-pixel compensation?”

-

Reputable factories like Sostron provide 2%-5% spare modules, all from the same production batch.

-

-

“Is the cabinet made of iron or die-cast aluminum?”

-

For high-density P2.5 displays, iron cabinets have poor heat dissipation and precision, often resulting in black lines over time. Engineering teams should insist on 51mm-thick die-cast aluminum cabinets, like Sostron’s Storm Plus series.

-

Sostron’s Turnkey Solutions: From Mexico to Malaysia

We provide more than modules; we deliver tailored turnkey solutions:

-

High-end Retail/Luxury Stores: Reta 2 series, just 30mm thick, cableless design. Minimal installation time and zero cable failure are key reasons clients, such as our Mexico P2.5 project, choose Sostron.

-

Retail & Exhibitions: sPoster smart poster display, supports cloud app control and plug-and-play setup, ideal for rapid deployment and synchronized multi-unit setups.

FAQ: Common P2.5 LED Module Questions

Q1: Why does my P2.5 display ripple when filmed?

A: The refresh rate is insufficient. Specify a 3840Hz high-refresh driver IC at purchase. This is especially critical for live-stage productions.

Q2: Can indoor P2.5 modules be adapted for outdoor use?

A: Absolutely not. Indoor modules typically have 600-800 nits brightness, insufficient for sunlight, and lack IP65 protection. Exposure to rain or humidity will damage the driver IC instantly. For outdoor use, see our ARES 2 energy-efficient outdoor series.

Q3: How does 14 years of experience and national high-tech certification benefit buyers?

A: It ensures reliability throughout contract fulfillment. The LED industry evolves rapidly; choosing a company with a 15,000㎡ base guarantees that your 5-year warranty is valid and traceable.

Conclusion: Value Before Price

P2.5 indoor LED module pricing is more than a number; it reflects your brand image, operating costs, and maintenance burden. At Sostron, we don’t just sell displays—we reduce your communication and trust costs.

💡 Ready to elevate your visual experience?

[Click here to get the latest P2.5 wholesale price list]

Disclaimer

The market reference prices mentioned in this article are estimates based on supply chain costs and exchange rates at the time of writing and are provided for budgeting purposes only. Actual transaction prices may vary due to fluctuations in raw material costs (such as LED chips, precious metals, and aluminum), changes in exchange rates, logistics expenses, and your specific customization requirements (including non-standard designs or special mounting structures).

The product images and case examples shown are for illustrative purposes only. Sostron reserves the right to upgrade or modify product appearance and technical specifications as part of ongoing product development. Final delivery standards shall be subject to the technical specifications and contractual terms mutually confirmed by both parties.

References:

About Dylan Lian

Marketing Strategic Director at Sostron