Table of Contents

-

What Is a Custom 3D LED Display?

-

Before You Buy: The Engineering Truth Behind Naked-Eye 3D

-

The “Seamless” Myth: Why 90° Corner Precision & Refresh Rate Decide Success

-

The Economics of 3D: Why Common Cathode Technology Saves Real Money

-

Supply Chain Risk Control: How to Spot “Ghost Factories” vs. True Manufacturers

-

FAQ: Pricing, Glasses, Maintenance, and Content

-

Conclusion: Call to Action

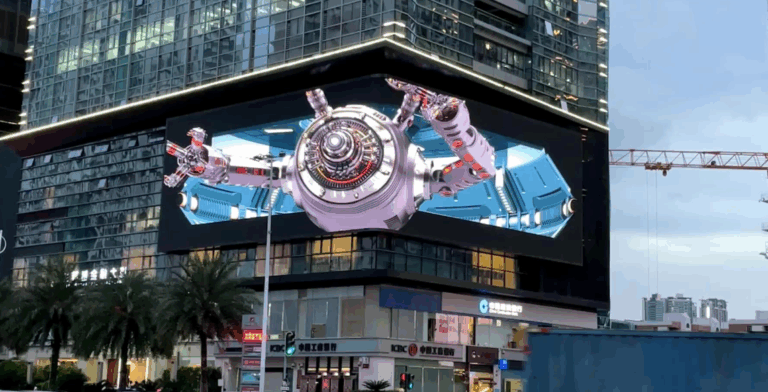

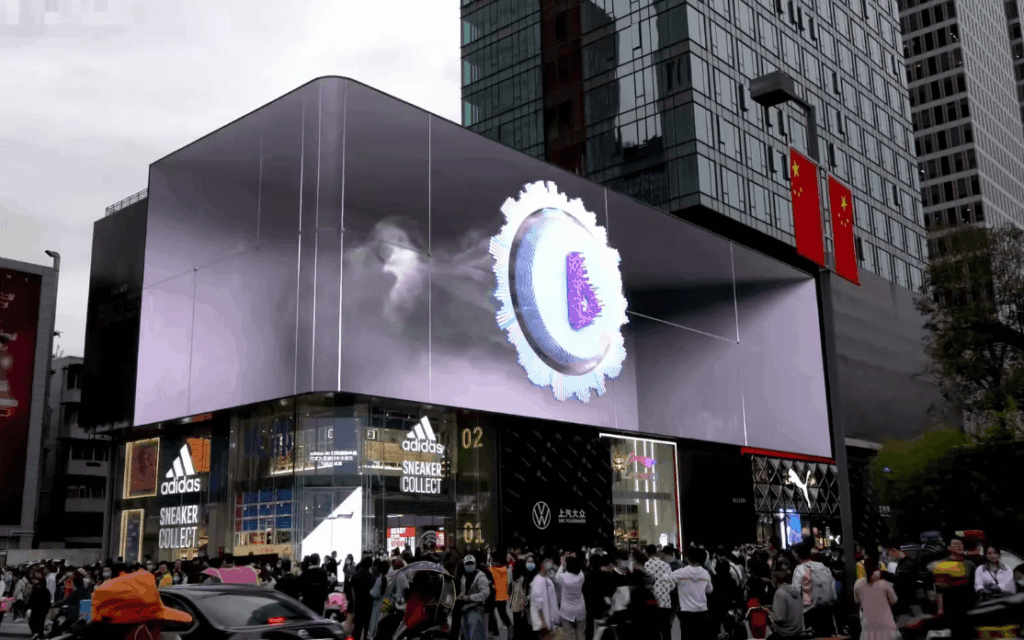

What Is a Custom 3D LED Display?

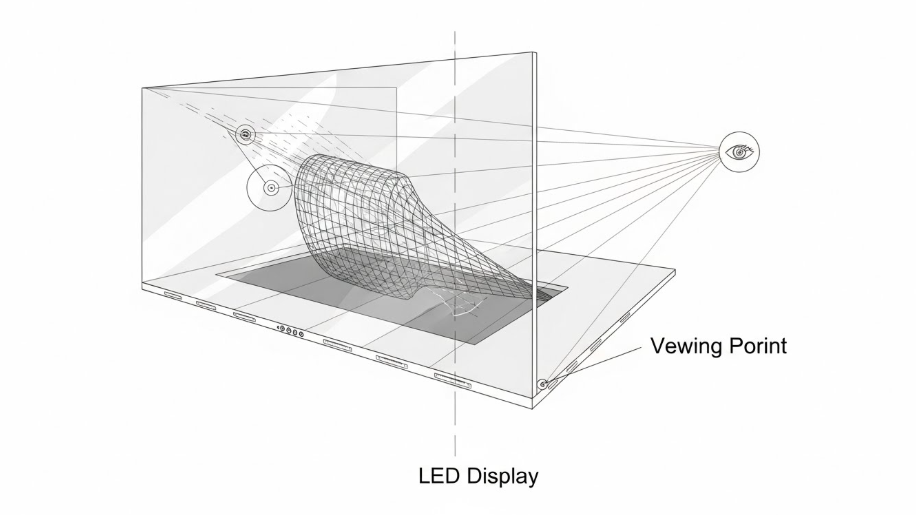

A Custom 3D LED Display uses anamorphic illusion technology combined with true 90° seamless corner modules to create a strong sense of depth from a fixed viewing point—without requiring 3D glasses.

Unlike standard flat LED screens, top-tier manufacturers such as Sostron rely on:

-

Profiled PCB cutting with micron-level accuracy

-

Common Cathode energy-saving architecture

This ensures perfect alignment between physical pixels and the video’s perspective point, while reducing Total Cost of Ownership (TCO) for 24/7 outdoor operation by over 40%.

Before You Buy: The Engineering Truth Behind Naked-Eye 3D Billboards

Don’t be fooled by demo videos of spaceships and lions leaping off the screen.

After 20 years in the supply chain, here’s the hard truth:

Most failed 3D projects don’t die because of content—they die because of hardware precision.

Many event companies and real estate developers believe that buying a bright screen and hiring an animation studio is enough. That assumption is expensive and wrong.

Naked-eye 3D relies on binocular parallax to trick the brain. This means the physical corner of the screen must be nearly “invisible.”

If you force standard flat panels with tolerances over 1 mm into a corner, viewers won’t see a lion jumping out—they’ll see a black seam that instantly destroys immersion.

At Sostron’s 15,000 m² intelligent manufacturing base, we’re not just assembling screens.

We’re building precision optical instruments.

Below are the technical realities most traders won’t tell you.

The “Seamless” Lie: Why Hardware Precision Matters More Than Content

Micron-Level Battle at a 90° Corner

Over 90% of so-called “seamless corners” on the market are just crude cut-and-join solutions.

Low-end approach:

-

Cutting standard cabinets at an angle

-

Forcing panels together

-

Filling gaps with sealant

What happens next?

-

Thermal expansion causes sealant cracking

-

Black seams turn into bright lines

-

The 3D effect collapses completely

Sostron’s approach:

-

CNC-machined die-cast aluminum cabinets

-

Custom chamfered PCB design

-

Reconstructed pixel pitch continuity across the corner

Our standard tolerance is < 0.1 mm.

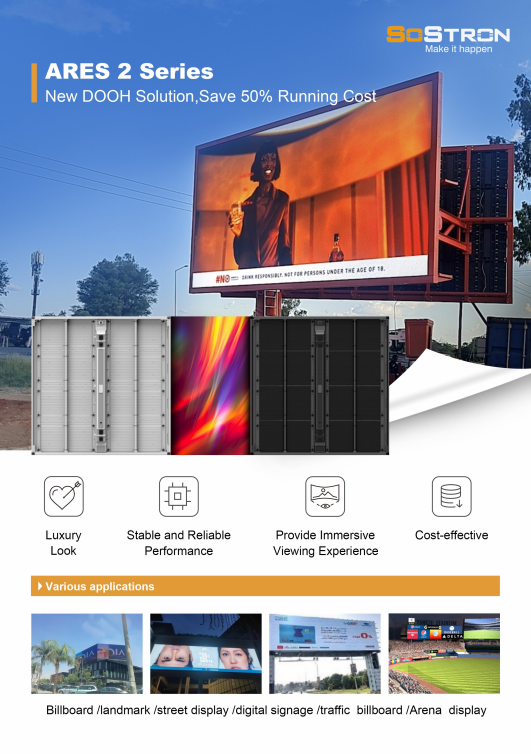

For high-end products like the ARES 2 Series, we even redesign the edge LED layout, ensuring no dark zones—even from side angles.

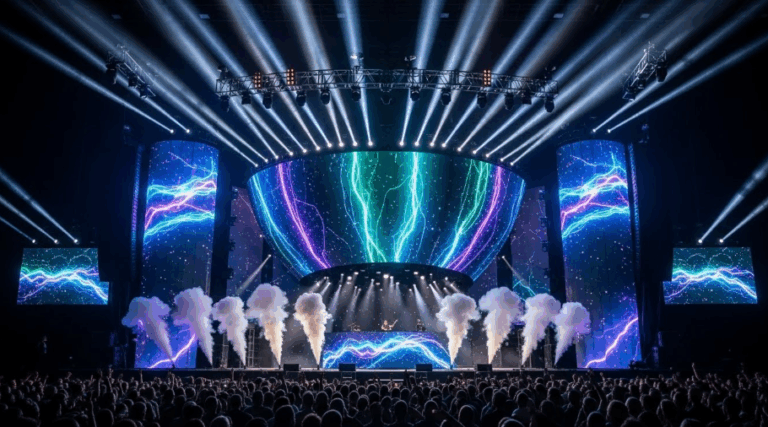

Refresh Rate & the “Secondary Exposure” Disaster

The real commercial value of naked-eye 3D lies in social media amplification (TikTok, Instagram, Reels).

A screen with 1920Hz refresh rate may look fine to the naked eye—but once filmed by a smartphone, it produces scan lines and moiré patterns.

For viral campaigns, that’s fatal.

Technical minimums:

-

3840Hz – absolute baseline

-

7680Hz – recommended for premium landmarks & XR stages

Grayscale depth matters too

3D relies heavily on shadows to create depth.

If the driver IC is below 14-bit, you’ll see color banding, flattening the 3D illusion.

Spec & Scenario Matching Guide

Smaller pixel pitch isn’t always better.

Using P2.5 outdoors for long-distance viewing is simply burning budget.

| Scenario | Recommended Pitch | Brightness (Nits) | Recommended Sostron Series | Key Reason |

|---|---|---|---|---|

| Urban landmarks / intersections | P5 / P6 / P8 | 6,000–10,000 | ARES 2 Series | All-aluminum cooling, 24/7 stability |

| Shopping malls / flagship stores | P2.5 / P3 | 800–1,500 | Reta 2 / Storm Pro | Fanless, silent, smooth close-up viewing |

| Glass façades / auto dealerships | P3.9 / P10 | 5,000+ | Transparent Crystal | 60% transparency, daylight preserved |

Real-World Case: Cairo, Egypt

For a highway project in Cairo, facing extreme heat and sandstorms, Sostron deployed a massive outdoor display using the ARES all-aluminum structure.

Instead of standard steel cabinets, the result was:

-

Higher contrast

-

Exceptional weather resistance

-

A true nighttime landmark—not light pollution

The Economics of 3D: ROI & TCO Breakdown

Most decision-makers focus on FOB price.

As a supply chain director, I’ll be blunt:

Electricity and maintenance—not hardware—kill your profit.

Power Consumption: The Hidden Cost Trap

A 300 m² outdoor 3D screen using Common Anode power is like driving a truck with the accelerator floored all day.

All RGB chips receive the same high voltage.

Excess voltage becomes heat.

Sostron’s Solution: Common Cathode Technology

The ARES 2 Series uses dual-channel precision power delivery:

-

Red LEDs: 2.8V

-

Blue/Green LEDs: 3.8V

Result:

-

30–50% energy savings

-

Surface temperature reduced by ~15°C

-

No need for massive air-conditioning systems

Lifespan & Color Shift

Heat is the enemy of LEDs.

In high temperatures, blue chips degrade faster, causing yellowing within a year.

For 3D displays that rely on color contrast, this equals failure.

Sostron’s low-temperature operation ensures color consistency for 5+ years.

5-Year Total Cost of Ownership (300 m² P6 Outdoor Screen)

Assumptions:

-

14 hours/day operation

-

Electricity: $0.15/kWh

| Cost Item | Standard Common Anode | Sostron ARES 2 (Common Cathode) | 5-Year Savings |

|---|---|---|---|

| Initial hardware | Lower upfront | +15% upfront | — |

| Electricity | ~$200,000 | ~$120,000 | $80,000 saved |

| Cooling systems | Large AC required | None | $15,000 saved |

| Maintenance | High | Low | $10,000 saved |

| Total 5-Year Cost | Highest | Lowest | Sostron wins |

💡 Expert Insight:

Electricity savings alone typically recover the price difference within 2 years.

Supply Chain Vetting: Factory or Middleman?

In Shenzhen, thousands claim to be “LED manufacturers.”

Many are just office-based traders.

For complex 3D projects, choosing a trader is a recipe for disaster—they don’t control tolerances or understand structural mechanics.

The “Ghost Factory” Trap

True custom 3D displays require structural engineers.

Sostron provides:

-

Wind load calculations

-

Steel structure stress analysis

-

Project-specific engineering drawings before production

Typical traders provide:

-

Generic CAD files

-

Installation surprises

-

Delays and rework on-site

Sostron Manufacturing Standards

At our 15,000 m² facility, every 3D module undergoes:

-

72-hour high-temperature aging

-

100% inspection (not sampling)

Dead pixel rate before shipment: < 3 per million.

Industry Standard vs. Sostron

| Feature | Industry Average | Sostron Standard |

|---|---|---|

| Module flatness | ±0.5 mm | ±0.1 mm (CNC) |

| Waterproofing | IP65 (sealant-based) | IP65/IP66 (structural + potting) |

| Spare parts | 1% random batch | 3% same-bin, same-batch |

| After-sales | 48–72 hrs | 24/7 engineer direct access |

FAQ – The Questions Executives Actually Ask

Q1: How much does a custom naked-eye 3D display cost?

A: There’s no single price. Depending on pixel pitch, brightness, and energy configuration, expect $800–$3,000 per m².

ARES 2 may cost more upfront, but TCO is significantly lower.

Q2: Do viewers need special glasses?

A: No. This is naked-eye 3D, achieved through hardware geometry and anamorphic content.

Q3: What if a module fails?

A: 3D displays are usually installed high. Front maintenance is mandatory.

Sostron’s patented quick-lock system allows module replacement from the front in 10 seconds—no rear access required.

Q4: Does Sostron provide 3D content?

A: We provide pixel-to-content mapping templates to ensure correct perspective.

We also collaborate with top global content studios for full turnkey solutions.

Conclusion: Don’t Let Cheap Hardware Ruin Your Landmark

Investing in naked-eye 3D is really an investment in a city-scale sculpture.

Saving 10% upfront by choosing poor cooling, loose tolerances, and visible seams only gets you:

-

Heat

-

Black lines

-

A very expensive piece of electronic waste

Sostron doesn’t just sell screens.

We deliver 14 years of proven industrial-grade precision, energy efficiency, and reliability.

From ARES 2’s extreme energy savings to our 15,000 m² manufacturing guarantee, we’re ready to turn your concept into reality.

👉 Next Steps

Don’t quote blindly.

Schedule a factory video tour to see our CNC processes firsthand, or contact our engineers for a free project-specific TCO analysis.

Disclaimer

The market reference prices mentioned in this article are estimates based on supply chain costs and exchange rates at the time of writing and are provided for budgeting purposes only. Actual transaction prices may vary due to fluctuations in raw material costs (such as LED chips, precious metals, and aluminum), changes in exchange rates, logistics expenses, and your specific customization requirements (including non-standard designs or special mounting structures).

The product images and case examples shown are for illustrative purposes only. Sostron reserves the right to upgrade or modify product appearance and technical specifications as part of ongoing product development. Final delivery standards shall be subject to the technical specifications and contractual terms mutually confirmed by both parties.

References: