Table of Contents

ToggleTable of Contents

-

The “Achilles’ Heel” of 3D Visual Assets: Why Maintenance Costs Are Higher than Standard Displays

-

Core Technology Insights: How Driver ICs, Thermal Management, and 3D Depth Affect Long-Term Costs

-

Supply Chain Secrets: A 5-Year TCO (Total Cost of Ownership) Analysis

-

B2B Buyer’s Guide: How to Spot Maintenance “Black Holes”

-

FAQ: Tough Questions About 3D LED Maintenance

-

Sostron Solutions: From a 15,000㎡ Smart Manufacturing Base to Extreme Energy Efficiency

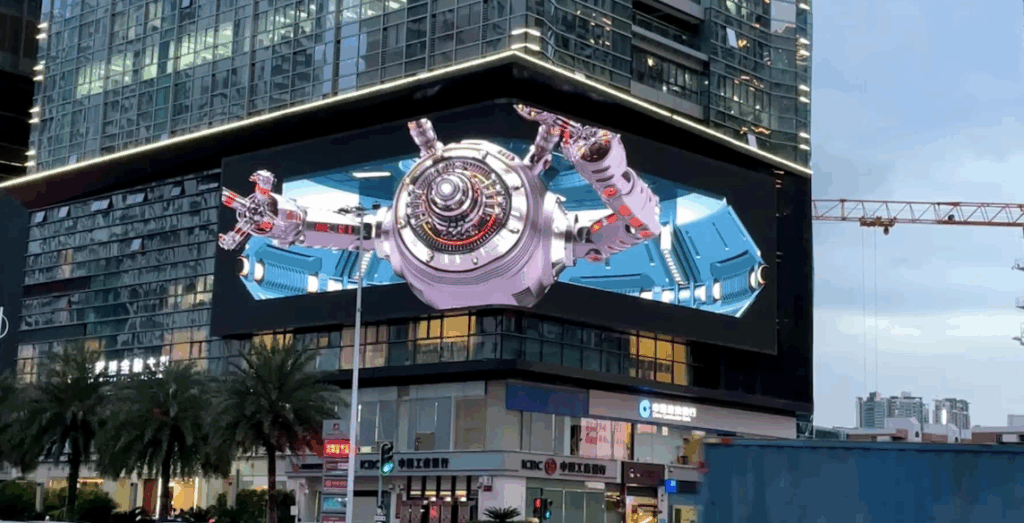

Large 3D LED walls (glasses-free 3D displays) incur maintenance costs that extend beyond simple repair expenses. They include energy consumption, hardware degradation and repair, calibration services, and lost business opportunities due to downtime. Typically, the annual maintenance budget for an industrial-grade 3D LED system should be set at 3%–8% of the initial investment. Poor initial selection can push this figure over 15% by the third year, directly cutting into advertising revenue.

1. The “Achilles’ Heel” of 3D Visual Assets: Why Maintenance Costs Are Higher than Standard Screens

As a supply chain director with 20 years of experience, I can confirm: a 3D screen is not just a display—it’s a precision optical instrument.

For standard flat panels, a few dead pixels are often negligible. But 3D screens rely on human binocular vision. A single module with color shift or physical misalignment can instantly collapse the 3D effect into a blurry flat image.

-

The Cost of Physical Gaps: 3D walls often feature L-shaped or curved corners. Even a 0.1mm structural gap can create visual breaks at the corner, and restructuring is far more costly than simply replacing modules.

-

Content Adaptation Costs: 3D video sources must align perfectly with the hardware. Brightness loss due to aging requires re-tuning the player’s gamma curves. This kind of “hardware-software coordinated maintenance” is something traditional advertising firms cannot handle alone.

2. Core Technology Insights: Driver ICs, Thermal Management, and 3D Depth

Reducing long-term maintenance starts with the hardware logic itself. The ARES 2 Series can cut operational costs by 50%, primarily by addressing the hidden culprit: thermal degradation.

| Technical Parameter | Low-Tier Solution | Sostron Industrial Solution (ARES 2) | Maintenance Impact |

|---|---|---|---|

| Driver Architecture | Common Anode | Common Cathode | Reduces heat by 30%, extends IC lifespan, lowers dead-pixel rate |

| Refresh Rate | 1920Hz–3840Hz | Up to 7680Hz | High refresh rate reduces driver chip load, minimizing long-term brightness decay |

| Cabinet Material | Basic steel / profile | Full aluminum (high thermal conductivity) | Doubles heat dissipation, prevents electronic migration failures from high temperatures |

| Calibration Technology | Factory one-time | Full-lifecycle point-by-point | Maintains 3D depth even after 5 years of use |

3. Supply Chain Secrets: 5-Year TCO Structure

For factory owners and procurement managers, unit price is key. For supply chain directors, TCO (Total Cost of Ownership) reveals the real picture.

For a 100㎡ outdoor 3D project, the ARES series’ high-brightness, energy-efficient design (up to 10,000 nits) is not just about combating sunlight—it also enables low-power operation to slow hardware fatigue.

| Cost Item | Low-Cost Option (USD) | Sostron High-End Solution (USD) | Expert Notes |

|---|---|---|---|

| Initial Purchase | $80,000 | $110,000 | High-quality screens cost 37% more upfront |

| 5-Year Electricity | $120,000 | $60,000 | Sostron energy-saving tech saves $60,000 |

| Spare Parts / Replacements | $25,000 | $5,000 | Low-tier ICs start failing massively after 2 years under high heat |

| Downtime Loss | $40,000 | $2,000 | Ad downtime from maintenance |

| Total TCO (5 Years) | $265,000 | $177,000 | Nearly $90,000 saved with high-quality screens |

Curious how much you could save on electricity for your project? [Click here for a precise quote.]

4. B2B Buyer’s Guide: How to Spot Maintenance “Black Holes”

Based on 14 years in the field, here are three key industry insights to filter out 90% of after-sales headaches during procurement:

-

Same-Batch LEDs Required: Always ensure suppliers reserve 3–5% of same-batch LEDs as spares. 3D screens cannot tolerate “patching”—even identical specifications from a different batch can break 3D depth due to slight color differences.

-

Avoid “Fake High Refresh”: Many low-end screens claim 3840Hz refresh, but overheat at full brightness. Professional 3D screens (e.g., Sostron Hima or Storm Pro) must maintain full-time high refresh, relying on driver IC PWM capabilities, not simple overclocking.

-

True IP Rating Matters: Some suppliers claim IP65 only on the front. ARES 2 uses double-sided glue encapsulation, crucial for coastal or rainy regions (e.g., our Brazilian highway project) to prevent irreversible PCB corrosion.

5. FAQ: Tough Questions About 3D LED Maintenance

Q: Your screens cost 20% more. When will I break even?

A: TCO analysis shows that electricity savings alone typically offset the premium within 18–24 months. The following 3 years are pure profit.

Q: If a driver IC burns out, do I need to dismantle the whole screen?

A: No. Sostron’s Storm Plus series supports full front maintenance. Modules can be replaced in 30 seconds with magnetic tools—no need to dismantle the structure.

Q: What if an overseas project fails? Will you send engineers?

A: Our CMS cloud control system provides real-time alerts. Most issues are resolved remotely. For hardware replacement, our 14 years of global supply chain experience ensures spares arrive on-site via expedited logistics.

6. Sostron Solutions: From a 15,000㎡ Smart Manufacturing Base to Extreme Energy Efficiency

As a national high-tech enterprise, Sostron offers not just screens, but a full low-maintenance asset solution.

-

R&D Strength: A 4,000㎡ research center focuses on thermal simulation, ensuring every Carbon Pro rental screen dissipates heat efficiently—even without fans—during tours.

-

Manufacturing Assurance: 15,000㎡ smart factory enforces 72-hour full-brightness aging tests, keeping pixel outage rates far below industry standards of 0.01%.

-

Classic Case: At a Chilean music festival, our Carbon Family series withstood frequent installation wear and tear and passed 4K camera inspections thanks to 7680Hz high refresh rate.

Conclusion: Predictable ROI Through Sostron

Large 3D LED walls are a balance between visual impact and operational cost. By choosing suppliers with common-cathode energy-saving technology, full-aluminum heat dissipation, and long-term calibration capabilities, you can transform high maintenance costs into stable profits.

Next Steps: Planning a landmark 3D advertising project? [Schedule a visit to our 15,000㎡ smart manufacturing base] or [get a customized 5-year ROI cost analysis report]. Let data guide your investment decisions.

References:

LED Component Interface Standards

About Dylan Lian

Marketing Strategic Director at Sostron