Table of Contents

ToggleDefinition & Core Advantages: Why Must Cylinder Displays Be Flexible?

A Flexible LED Cylinder Display is a fully seamless 360° visual system built with flexible PCB circuitry and magnet-mounted LED modules. Unlike traditional hard-panel cylinder screens that rely on angled segmentation, flexible designs achieve a true physical curve—with a minimum bending radius as small as 150 mm—eliminating visible creases, seams, and black lines entirely.

For production companies, system integrators, and export-focused manufacturers, the rationale behind choosing flexible solutions is straightforward:

-

True Physical Seamlessness

Traditional hard-panel cylinders still show visible edges beyond 2 meters. Flexible modules at P2.0–P2.5 pixel pitch achieve visually imperceptible transitions—even at close viewing distances. -

Front-Service Efficiency

100% magnetic front maintenance allows single-module replacement in under 15 seconds. In shopping mall columns or touring stage setups, this feature is not a luxury—it’s a lifesaver.

In-Depth Technical Breakdown: Engineering Behind Flexible Modules

From an engineer’s perspective, a premium cylinder display isn’t just about bending—it’s about electrical stability under continuous curvature.

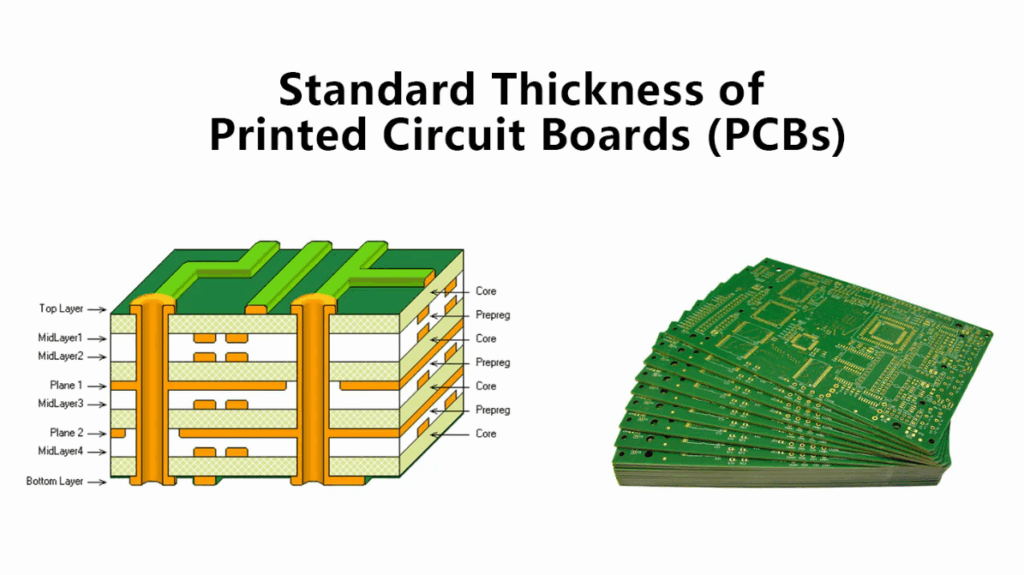

PCB Layer Constraints

Because flexible modules remain under long-term tensile and compressive stress, Sostron uses 4-layer high-TG flexible PCBs as standard.

-

Market Comparison

Many low-cost solutions rely on 2-layer PCBs. Under prolonged heat cycles, these boards are prone to solder joint fatigue and cracking, resulting in large-scale dead pixels. -

Verified Performance

Sostron modules withstand over 10,000 bending cycles, ensuring circuit integrity even under frequent assembly and disassembly in rental applications.

Driver ICs & Refresh Rates (XR & Broadcast Applications)

To meet professional production requirements, Sostron typically deploys MBI5153 or higher-grade driver ICs.

-

Key Specification

Refresh Rate: ≥ 3840Hz up to 7680Hz -

Why It Matters

Only 7680Hz refresh ensures zero scan lines or moiré artifacts under 1/32 scan when captured by high-speed broadcast cameras—a non-negotiable requirement for XR studios, auto shows, and premium live events.

Commercial Value & Cost Structure: Choosing the Right Solution

As a buyer, you must be clear whether you’re purchasing a decorative asset or a revenue-generating production tool.

Table 1: Flexible LED Cylinder Display Comparison by Pixel Pitch

| Parameter | P1.875 (Flagship) | P2.5 (Best Value) | P4 (Long-View) |

|---|---|---|---|

| Optimal Viewing Distance | 1.8–10 m | 2.5–15 m | 4–25 m |

| Minimum Cylinder Diameter | 300 mm | 480 mm | 760 mm |

| Module Size | 240×120 mm | 320×160 mm | 320×160 mm |

| Typical Applications | Luxury retail, corporate showrooms | Mall columns, performance venues | Airports, large public spaces |

| ROI Profile | Maximum brand premium | Fast payback, low maintenance | Lowest upfront investment |

Cost Composition Insight

In a typical cylinder display budget:

-

LED modules: 60%

-

Custom steel structure: 20%

-

Control systems & labor: 20%

Never cut corners on structural steel. A misalignment of just 1 mm can amplify visible seams dramatically once the display is assembled.

Supply Chain Insights: Identifying “Invisible Downgrades”

With over 20 years in the LED industry, certain hidden shortcuts deserve to be exposed:

-

LED Chip Substitution

Even when labeled “copper wire LEDs,” Nationstar LEDs exhibit ~40% lower luminance decay compared to off-brand alternatives. Inferior LEDs often show color banding and uneven brightness within one year. -

Power Supply Headroom

Many suppliers size power supplies at only 80% peak load. Sostron maintains 20% power redundancy, reducing thermal stress and cutting failure rates by up to 3×, even during full-white summer operation. -

Magnet Density

Cylinder displays rely entirely on magnetic fixation. Cost-driven designs reduce magnet count, leading to surface bulging or long-term slippage.

Sostron standard: 16–20 high-strength magnets per module for absolute flatness.

Sostron Solutions: SPad Pro2 & Chile Music Festival Case

Flagship Product: SPad Pro2 Series

Designed for both creative rentals and permanent installations, SPad Pro2 represents Sostron’s top-tier flexible platform.

-

Supports S-curves, concave, convex, and full cylinders

-

7680Hz refresh rate for flawless on-camera performance

-

Rental-optimized quick-lock system, improving installation speed by 50%

Case Study: Large-Scale Music Festival in Chile

-

Configuration: Carbon Family carbon-fiber cabinets combined with flexible SPad modules

-

Challenges: Outdoor conditions, IP65 protection required, ultra-lightweight suspension limits

-

Results:

Carbon-fiber cabinets weighing only 5 kg per unit, combined with curved module edges, delivered an immersive 3D visual experience for 50,000+ attendees.

A 3840Hz refresh rate ensured pristine broadcast footage.

Call to Action

Not sure which pixel pitch fits your project?

[Get Full Product Price List] | [Schedule a Tour of Sostron’s 15,000㎡ Manufacturing Facility]

Buyer’s Pitfall Guide: 5 Questions That Expose Weak Suppliers

Ask these questions to instantly assess a manufacturer’s competence:

-

“Is your flexible PCB 2-layer or 4-layer? What’s the TG rating?”

Expected answer: 4-layer, TG170+ -

“How do you eliminate image tearing at the 360° seam?”

(Evaluates sending/receiving card synchronization) -

“Are the module magnets injection-molded or glued?”

(Glue degrades under heat; integrated molding is more reliable) -

“How do you ensure color consistency if I replace modules after two years?”

(Batch reservation and color calibration capability) -

“Are the power supplies certified for export markets (UL, ETL, CE)?”

(Critical for legal and compliance risk control)

FAQ: Common Questions About LED Cylinder Displays

Q1: Does a smaller radius always cost more?

Yes. A smaller radius requires narrower modules and more complex PCB and LED layouts. For pitches below P2.5, a minimum diameter of 400 mm is recommended for optimal visuals.

Q2: How do you calculate resolution for a cylinder display?

Formula:

-

Horizontal pixels = Circumference ÷ Pixel pitch

-

Vertical pixels = Height ÷ Pixel pitch

Example:

1 m diameter, P2.5 → (3141 ÷ 2.5) ≈ 1256 horizontal pixels

Q3: Can cylinder displays be used outdoors?

Yes—but only with ARES-series or flexible modules featuring dual-sided IP65 potting.

Standard indoor flexible modules must never be used outdoors—even with glass protection—due to heat dissipation and UV-induced PCB degradation.

Conclusion: Turning Every Column Into a Profitable Art Piece

Over 14 years, Sostron has witnessed countless projects fail because buyers chased a 15% lower upfront cost, only to face costly reinstallation later. A cylinder display is not just a screen—it’s the visual soul of the space.

From our 15,000㎡ intelligent manufacturing base, every minute produces displays certified to CE, RoHS, FCC, and UL standards. Whether you need the extreme energy efficiency of ARES 2 or the lightweight stage performance of Carbon Pro, our 4,000㎡ R&D center delivers full-chain support—from structural engineering to cloud-based CMS control.

Contact Sostron’s senior engineers today to receive a customized quotation.

Disclaimer

The market reference prices mentioned in this article are estimates based on supply chain costs and exchange rates at the time of writing and are provided for budgeting purposes only. Actual transaction prices may vary due to fluctuations in raw material costs (such as LED chips, precious metals, and aluminum), changes in exchange rates, logistics expenses, and your specific customization requirements (including non-standard designs or special mounting structures).

The product images and case examples shown are for illustrative purposes only. Sostron reserves the right to upgrade or modify product appearance and technical specifications as part of ongoing product development. Final delivery standards shall be subject to the technical specifications and contractual terms mutually confirmed by both parties.

References:

Macroblock MBI5153 LED Driver IC Datasheet

About Dylan Lian

Marketing Strategic Director at Sostron