For outdoor media operators, a low power outdoor LED billboard is not just a green marketing slogan—it is a matter of survival that directly impacts profit margins. While traditional common anode LED screens are quietly eating away up to 30% of your operating profit, a new generation of energy-efficient display technology has become a clear industry dividing line.

If you are actively looking for ways to reduce operational expenditure (OPEX), you are in the right place.

As a national high-tech enterprise with 14 years of manufacturing experience and a 15,000㎡ intelligent manufacturing base, Sostron has worked with hundreds of global event production companies and international trade clients. One pain point consistently stands out:

Customers are far less anxious about the initial purchase price than they are about long-term electricity bills and frequent dead-pixel repairs caused by overheating.

Drawing on measured data from our 4,000㎡ R&D center, this article reveals—right from the manufacturing source—how common cathode technology achieves 40%–50% energy savings, and helps you clearly calculate the real financial return.

Table of Contents

ToggleWhat Is a Low Power Outdoor LED Billboard? (The Technical Core)

Before talking about cost savings, we must first understand the technical logic behind “energy efficiency.”

Most so-called “energy-saving LED screens” on the market ultimately come down to one key question:

Does it use Common Cathode Technology?

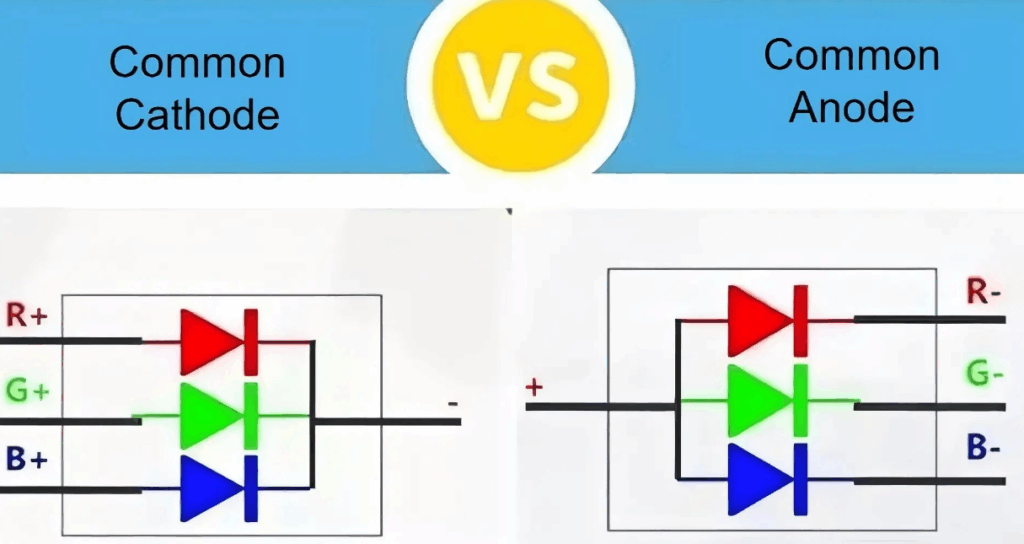

Traditional Common Anode Power Supply Explained

Most conventional outdoor LED displays use a common anode power supply. This approach is like flood irrigation—regardless of how much voltage red, green, or blue LEDs actually need, the power supply delivers a uniform 3.8V or even higher voltage to all of them.

The result?

Red LED chips, which only require about 2.8V, are forced to absorb excess power. That surplus energy doesn’t disappear—it turns directly into waste heat.

Sostron’s Solution: Precision Power Delivery

Sostron takes a precision drip irrigation approach.

Using our flagship ARES 2 Series as an example, it adopts an advanced common cathode architecture that precisely separates power delivery:

-

2.8V supplied directly to red LED chips

-

3.8V supplied to green and blue LED chips

No excess voltage.

No unnecessary heat generation.

Common Cathode vs. Common Anode: Three Critical Differences

To make the distinction crystal clear, here is a direct comparison:

| Key Metric | Traditional Common Anode Screen | Sostron Common Cathode Energy-Saving Screen | Your Benefit |

|---|---|---|---|

| Power Supply Method | Unified high-voltage supply; excess energy converted to heat | Independent R/G/B precision power delivery | 30%–50% energy savings, significantly lower electricity bills |

| Surface Temperature | Typically > 65°C (requires heavy air conditioning) | Reduced by ~20°C (typically < 45°C) | Saves on HVAC equipment and cooling costs |

| Color Performance | Long-term heat causes wavelength drift and color distortion | Low-temperature operation with stable color temperature | More accurate visuals, higher advertiser satisfaction |

Why “Low Power” Means a Longer Lifespan (Experience & Expertise)

Many procurement managers assume low power consumption is only about saving electricity.

Based on our manufacturing experience, the greatest hidden value of low power consumption is dramatically extending the screen’s service life.

Heat Is the #1 Killer of Electronic Components

For every 10°C increase in internal temperature, the failure rate of electronic components can double.

Thanks to common cathode cold-screen technology, combined with a full aluminum structural heat-dissipation design, the ARES 2 Series maintains stable temperatures without relying on high-speed internal fans.

This directly results in:

-

Slower brightness degradation – LEDs do not dim prematurely due to heat stress

-

Higher system stability – Power supplies and IC chips operate more reliably at lower temperatures

Real-World Case: Extreme Conditions in Southern France

In an outdoor project in southern France, a client installed a 6㎡ Ares Series P3.9 fixed outdoor LED display.

Challenge:

Intense summer sunlight and continuous exposure to high ambient temperatures.

Performance:

Thanks to the Ares Series’ 10,000 nits ultra-high brightness and common cathode energy-saving design, the display remains clearly visible under strong sunlight. Without installing additional heavy cooling systems, it has operated stably for over 3 years, with minimal brightness decay.

Conclusion:

This real-world deployment confirms our lab data—only by solving heat issues can you truly solve lifespan issues.

Real ROI Calculation: Let’s Do the Math (Authoritativeness)

For event company buyers and factory owners, purchasing decisions ultimately come down to the financial statements.

Many customers hesitate when they see that common cathode screens have a slightly higher upfront price.

However, according to financial data from long-term projects, once you calculate TCO (Total Cost of Ownership), the conclusion is very different.

A Realistic Commercial Scenario

Assume you install a 100㎡ outdoor LED billboard, operating 14 hours per day, with electricity priced at $0.20/kWh.

We compare a standard outdoor LED screen with Sostron’s ARES 2 Series (common cathode) over five years:

| Cost Category | Standard Outdoor LED (Common Anode) | Sostron ARES 2 Energy-Saving Screen | 5-Year Difference |

|---|---|---|---|

| Average Power Consumption | ~350 W/㎡ | ~180 W/㎡ | – |

| Daily Energy Use (100㎡) | 490 kWh | 252 kWh | 238 kWh saved per day |

| Annual Electricity Cost | $35,770 | $18,396 | $17,374 saved per year |

| Cooling / HVAC Cost | High-power AC running all day | Basic ventilation or small fans | ~$2,000 saved per year |

| Total 5-Year OPEX | > $188,850 | < $101,980 | > $86,000 saved over 5 years |

Numbers don’t lie.

In just about 1.5 years, electricity savings alone can offset the initial price premium. For the remaining 3.5 years or more, the screen is generating pure profit—not even counting reduced maintenance labor costs due to cooler operation.

Sostron’s Intelligent Manufacturing Advantage: More Than Just Energy Saving (Trust)

Why can Sostron achieve this level of efficiency?

Because low power consumption is not a single parameter—it is a complete system engineering approach.

4,000㎡ R&D Center Temperature Rise Testing

Every product labeled “low power” must pass extreme testing before mass production.

According to our internal lab standards, we simulate 60°C ambient temperatures (Middle East conditions) and ensure PCB surface temperature rise remains within safe limits at full load.

Structural Innovation: Storm Pro Die-Casting Process

Thermal performance is not only about circuitry—it’s also about structure.

Our high-end Storm Pro series replaces traditional steel cabinets with precision die-cast aluminum:

-

Steel cabinets: High heat retention, slow dissipation—like an oven

-

Die-cast aluminum: Excellent thermal conductivity with finned design for rapid heat transfer

This structural innovation allows lower energy consumption at the same brightness compared to competitors.

Deep Customization of Power Supplies and PCBs

As a national high-tech enterprise, Sostron does not use off-the-shelf power supplies.

We co-develop dual-channel output custom power supplies with top-tier manufacturers, specifically designed for our common cathode circuits—achieving over 90% power conversion efficiency.

Buyer’s Guide: Avoiding Pitfalls When Choosing Energy-Saving LED Screens

Many rebranding factories claim “energy saving” by simply lowering brightness. As a professional buyer, always verify the following:

Verify the Power Supply Method

Ask whether it is Common Cathode or Common Anode.

If the supplier cannot clearly explain voltage differences, consider that a red flag.

Request a Temperature Rise Report

Do not rely solely on spec sheets.

Request thermal images after 1 hour of operation. A true energy-saving screen should feel cool to the touch—often below body temperature.

Check the Brightness–Power Balance

Be cautious of screens claiming ultra-low power but only 3,000 nits brightness.

True technology (like the ARES Series) maintains 10,000 nits while reducing power consumption.

Inspect Protection Rating and Manufacturing Quality

Outdoor screens must withstand harsh environments. Confirm IP65/IP66 ratings and inspect potting quality—air bubbles reduce heat dissipation.

FAQ: Common Questions About Low Power LED Billboards

Q1: Does a common cathode energy-saving screen have lower brightness?

A: No. True common cathode technology (such as Sostron’s ARES Series) saves energy by optimizing power delivery—not by reducing brightness. In fact, lower heat improves LED efficiency, making 10,000 nits ultra-high brightness easily achievable.

Q2: If energy-saving screens save so much, why do people still buy common anode screens?

A: Mainly due to initial budget constraints. Common cathode screens require customized driver ICs and power supplies, making upfront costs about 15%–20% higher. However, for projects operating longer than one year, common anode screens are actually more expensive due to higher electricity and maintenance costs.

Q3: Can existing LED screens be upgraded to common cathode technology?

A: Unfortunately, no. Common cathode technology requires fundamental changes to PCB design, driver ICs, and power architecture. If your current screens consume too much power, we recommend gradually replacing them with next-generation solutions such as the Sostron Storm Series or ARES Series modules or complete displays.

Conclusion: Invest in a Green Future, Eliminate Hidden Costs

In an era of volatile energy prices, choosing a low power outdoor LED billboard is no longer optional—it is essential for cost control and efficiency.

From the common cathode innovation of the ARES 2 Series to the structural heat dissipation of Storm Pro, Sostron delivers display solutions that are affordable to buy—and even more affordable to operate.

Don’t let electricity bills eat into your advertising profits.

Ready to optimize your operational costs? Contact Sostron’s engineering team today for a free ROI diagnostic report tailored to your existing project.

References:

LED Technology & Power Consumption

LED Thermal Management & Reliability

About Dylan Lian

Marketing Strategic Director at Sostron