Table of Contents

-

Structural Principles: Internal Layout, Signal Path, and Thermal Design Logic

-

Key Parameter Comparison Table

-

Design Considerations

-

Manufacturing Process

-

Quality Control (QC)

-

Application Differences by Project Type

-

Failure Mode and Effects Analysis (FMEA)

-

Supply Chain Analysis

-

Procurement Recommendations (Engineering Perspective)

-

Conclusion

Selecting the right LED cabinet structure directly affects heat dissipation, reliability, installation accuracy, and product lifespan. Today’s mainstream LED display cabinets are primarily die-cast aluminum and sheet-metal structures. This article provides a comprehensive, engineering-level comparison across structural design, key parameters, manufacturing processes, quality control, application differences, failure patterns, and supply chain considerations.

1. Structural Principles: Internal Layout, Signal Chain, and Thermal Design Logic

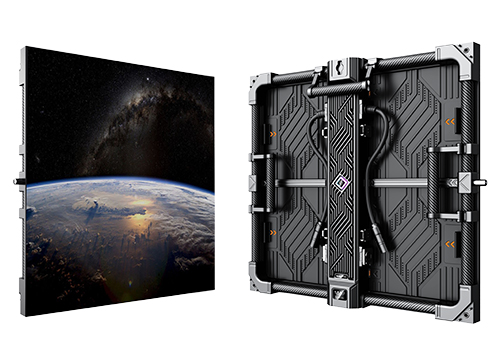

Die-Cast Aluminum Cabinets

Structural Principle:

Manufactured using high-pressure die-casting, the cabinet features strong overall rigidity with the front and side panels formed as a single piece. LED modules are typically secured with M2/M3 screws, and module spacing precisely matches the cabinet structure.

Signal Chain Layout:

Power supplies, receiving cards, and LED modules are arranged according to heat zones to ensure stable signal transmission and power distribution.

Thermal Design Logic:

Aluminum has excellent thermal conductivity (~200 W/m·K). The cabinet itself acts as a heat sink, eliminating the need for forced air cooling. Heat from the LED modules is transferred directly to the cabinet, with fins enhancing convection.

Sheet-Metal Cabinets

Structural Principle:

Constructed using welded or folded steel/aluminum plates. Structural strength is lower, and cabinet flatness depends heavily on welding and bending accuracy.

Signal Chain Layout:

Internal support frames and guide rails help modules slide in for installation, but thermal management relies mainly on air channels rather than conduction.

Thermal Design Logic:

Sheet-metal conductivity varies—steel is low (~50 W/m·K) while aluminum is higher (~200 W/m·K). These designs often require forced air cooling or thermal pads and still fall short of die-cast aluminum in heat dissipation efficiency.

2. Key Parameter Comparison Table

| Parameter | Die-Cast Aluminum Cabinet | Sheet-Metal Cabinet |

|---|---|---|

| Material Thickness | 2.5–4 mm | 1.0–2.0 mm |

| Flatness | ±0.2 mm | ±0.5 mm |

| Weight | Lighter (6–10 kg per cabinet) | Heavier (10–15 kg per cabinet) |

| Heat Dissipation | High (200 W/m·K) | Medium to Low (50–200 W/m·K) |

| Installation Precision | High (±0.2 mm) | Medium (±0.5 mm) |

| IP Rating | Up to IP65/IP66 | Typically IP54–IP65 |

| Module Alignment Repeatability | High | Medium |

| Wind Resistance | Strong | Weaker |

| Manufacturing Cost | Higher | Lower |

3. Design Considerations

Structural Tolerances

-

Die-cast aluminum: Mold accuracy determines flatness; space for thermal expansion (±0.1–0.2 mm) must be reserved.

-

Sheet-metal: Welding and bending tolerances are critical; verticality and flatness must be verified.

Thermal Design

-

Die-cast aluminum: Best suited for passive cooling; air channels or fans can be added when necessary.

-

Sheet-metal: Requires thermal pads, airflow channels, and fan designs to keep continuous-operation temperatures below 55°C.

Waterproofing

-

Die-cast aluminum cabinets typically integrate molded seals for IP65+ outdoor performance.

-

Sheet-metal cabinets need localized waterproof reinforcement, including sealed screw holes and gasketed connectors.

Power & Electrical

-

High-voltage AC (110/220V) and low-voltage DC zones must be separated to avoid thermal stacking.

-

EMC considerations: Die-cast aluminum naturally provides shielding; sheet-metal designs may require extra shielding treatments.

4. Manufacturing Process

SMT Production

-

LED module SMT: automatic placement (0402/0603/2020/2121, etc.), reflow soldering, AOI inspection

-

Driver IC and receiving card assembly and testing

Assembly Process

-

Cabinet inspection

-

Module insertion

-

Cable and connector installation

-

Power supply and controller card installation

-

Module alignment

-

Cabinet locking

Die-cast aluminum cabinets often use tool-less locking mechanisms, while sheet-metal versions rely more on screw fastening.

Aging Tests

-

High-temperature aging (45–60°C, 72 hours)

-

Power-cycle testing (full-screen/half-screen switching)

-

Waterproof and dustproof tests (spray/immersion)

5. Quality Control (QC)

| Stage | Inspection Content |

|---|---|

| IQC | Raw materials: aluminum thickness, surface treatment, steel type |

| IPQC | Cabinet flatness, screw-hole alignment, module fitting accuracy |

| FQC | Brightness, color uniformity, interface functions, power load |

| OQC | Full-screen inspection before shipment: waterproofing, dustproofing, vibration/transport simulation |

6. Application Differences

By Climate

-

Hot regions (Middle East/Africa): Die-cast aluminum preferred due to superior heat dissipation; sheet-metal requires forced cooling.

-

Humid regions (Southeast Asia): Die-cast aluminum provides better waterproofing; sheet-metal needs enhanced sealing.

By Application Scenario

-

Stadiums & large outdoor billboards: Die-cast aluminum for flatness and wind resistance.

-

Shopping malls & conference rooms: Sheet-metal provides adequate precision at lower cost.

-

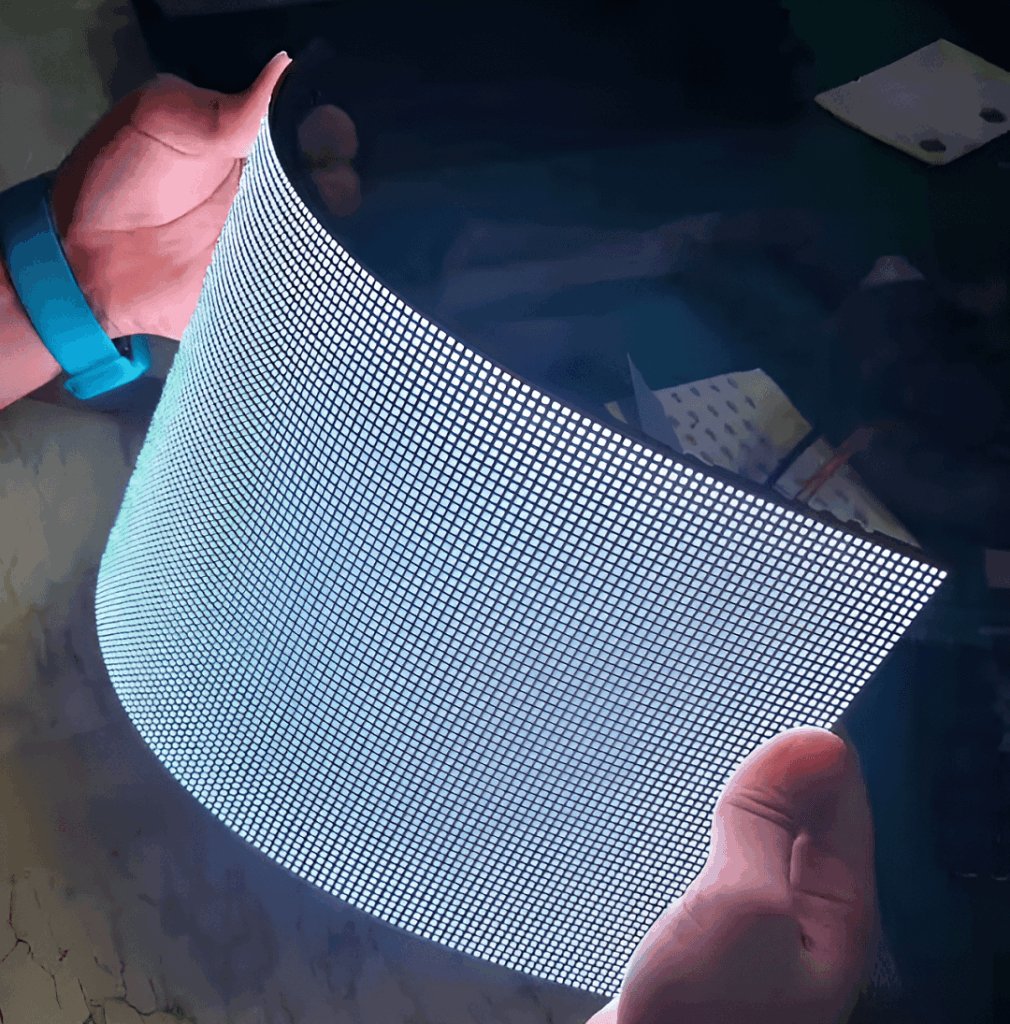

Rental/event screens: Die-cast aluminum is lighter, stronger, and installs quickly—ideal for repeated handling.

7. Failure Mode and Effects Analysis (FMEA)

| Failure Mode | Cause | Prevention |

|---|---|---|

| Module thermal failure | Poor heat conduction | Use die-cast aluminum or add thermal pads |

| Cabinet deformation | Strong wind load or thin sheet-metal | Increase material thickness; add support frames |

| Power failure | Overheating or poor circuit design | Zonal power design; thermal protection |

| Waterproof failure | Unsealed screw holes; aging seals | Use weather-resistant gaskets; waterproof screw treatments |

| Signal loss | Loose connectors; EMI interference | Secure connectors; improve shielding design |

8. Supply Chain Analysis

-

LED Chips: Prefer high-efficiency, low-power brands (Nichia, Cree, Epistar) for brightness and longevity.

-

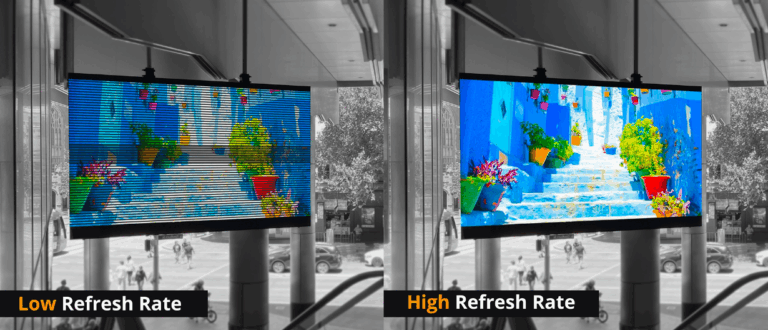

Driver ICs: Key factors include stability, refresh rate, and PWM accuracy.

-

Outdoor: MBI / CHIPONE

-

High-precision displays: TI / Novastar

-

-

Control System: Must balance resolution, refresh rate, and reliability; compatibility between controller and receiving cards is essential.

-

Cabinet Suppliers:

-

Die-cast aluminum: choose suppliers with strong mold-making expertise.

-

Sheet-metal: focus on welding and bending accuracy.

-

9. Procurement Recommendations (Engineering Perspective)

-

For projects requiring high flatness, long outdoor lifespan, or strong thermal performance → Choose die-cast aluminum cabinets.

-

For budget-sensitive projects in controlled indoor environments → Sheet-metal cabinets are sufficient.

-

For rental and mobile applications with frequent transport → Die-cast aluminum is the clear winner.

-

In hot or humid environments, pay close attention to IP rating, thermal capability, and module stability, not just price.

10. Conclusion

Die-cast aluminum and sheet-metal LED cabinets both have strengths and limitations. The right choice depends on structural requirements, thermal management, electrical safety, operating environment, and long-term maintenance considerations.

Die-cast aluminum excels in high-precision, outdoor, and high-strength applications, while sheet-metal offers cost-effective performance for indoor and low-load installations. With proper engineering design, strict quality control, and a well-managed supply chain, the reliability and lifespan of LED displays can be significantly improved.

References: