Table of Contents

-

Supply Chain Reality: Why 90% of Failures Come from What You Can’t See

-

Technical Deep Dive: Opening the “Black Box”

-

Business Value Analysis: Why “Cheap” Ends Up Being Expensive

-

Pitfall Avoidance Guide: How Experts Spot the Real Thing

-

FAQ: Straight Answers for Procurement Managers

-

The Sostron Solution: More Than Just Modules

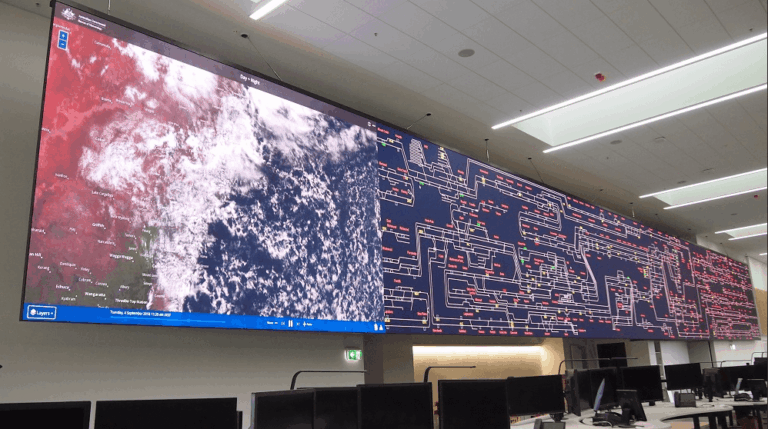

Introduction: Why P6 Is the Gold Standard—And Also the Most Abused

The P6 Outdoor SMD Waterproof LED Module is widely recognized as the gold standard for outdoor digital billboards. Designed for an optimal viewing distance of 6 to 60 meters, it typically uses SMD3535 LED packaging, requires brightness above 5,500 nits to combat direct sunlight, and must meet IP65 front-side waterproofing standards.

On paper, everything looks simple.

In reality, P6 modules that look identical can be priced anywhere from $15 to $35 per module. The difference isn’t branding or luck—it’s the Bill of Materials (BOM). That BOM determines whether your screen will operate reliably for five years, or turn into a patchwork of dead pixels after six months.

1. Supply Chain Reality: Why 90% of Failures Come from What You Can’t See

After 20 years in the LED display industry, I’ve seen the same mistake repeated by rental companies and international buyers alike:

they obsess over price per square meter, while ignoring Total Cost of Ownership (TCO).

A quotation that reads:

“P6 Outdoor, Nationstar LEDs, 1920Hz”

does not mean you’ve won.

Specifications can be exaggerated. Physics cannot.

Outdoor environments are unforgiving—heat, humidity, salt air (coastal cities), and UV exposure relentlessly attack your screen.

The Typical Failure Timeline of a Low-Cost P6 Module

-

Month 1: Everything works perfectly.

-

Month 3: Subtle color shift appears (white balance drift), usually caused by yellowing of low-grade encapsulation glue.

-

Month 6: After the first heavy rain, “caterpillar effects” appear (row scanning shorts). Dead pixel rate exceeds 0.03%.

-

Month 12: Module warping causes light leakage at seams, forcing expensive high-altitude maintenance.

To avoid this, you must evaluate three core technical indicators like an expert.

2. Technical Deep Dive: Opening the “Black Box”

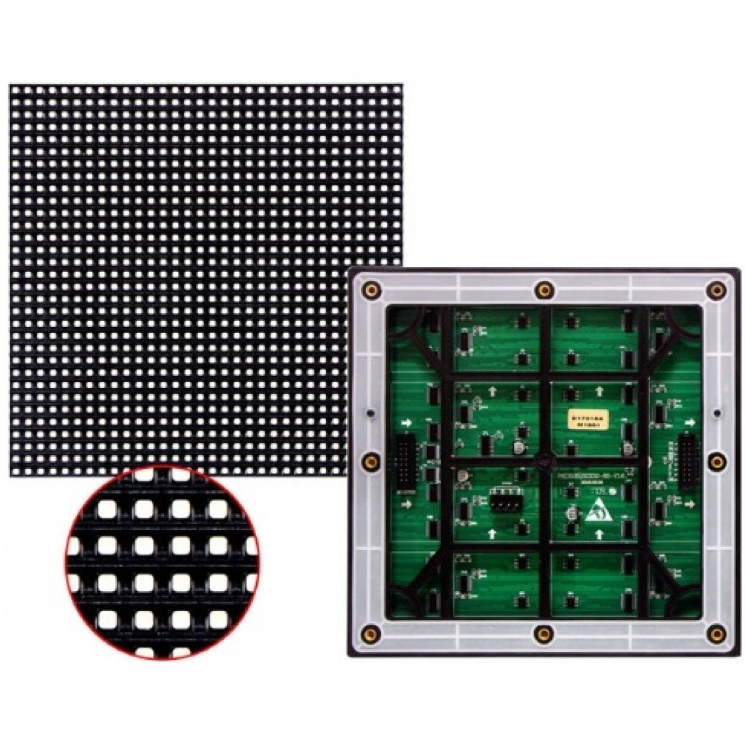

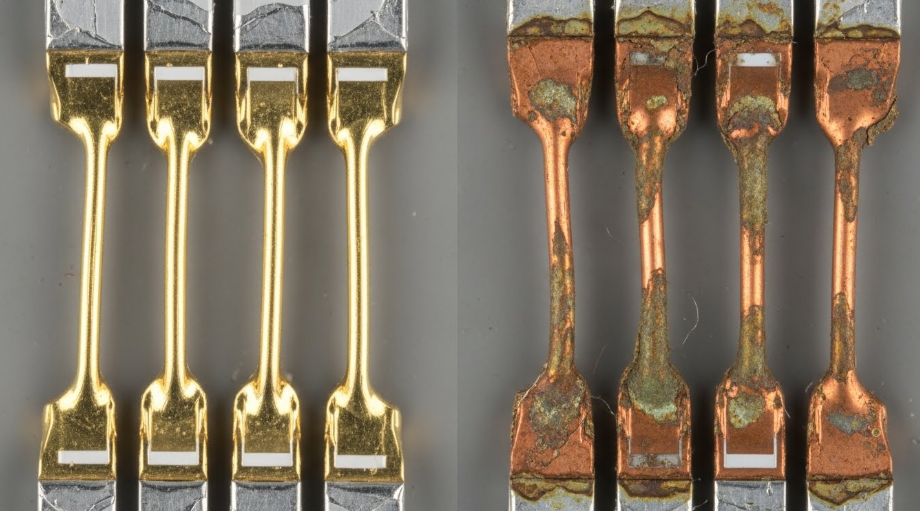

2.1 LED Packaging: Gold Wire vs. Copper Wire

(Where 40–50% of the Cost Difference Hides)

Market Reality:

Many suppliers claim to use Nationstar LEDs. What they don’t say is that Nationstar offers multiple grades. To reduce costs, many factories use copper wire bonding, or even iron lead frames.

Sostron Standard:

For core products like the Ares Fixed Outdoor Series, we insist on 99.99% pure gold wire bonding.

The Physics:

Copper has far less ductility than gold. Under daily thermal expansion and contraction, copper wires fracture easily. Worse still, in high-humidity or salt-air environments—such as Dubai, Singapore, or coastal Brazil—copper oxidizes within 6–12 months, inevitably leading to dead LEDs.

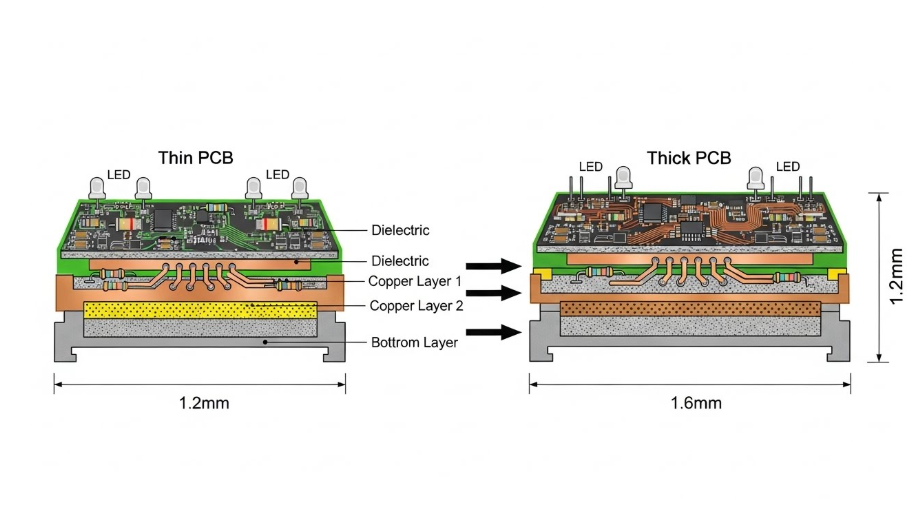

2.2 PCB Board Thickness: Why 1.6mm Matters

A P6 module has a pixel density of 27,777 dots/m², meaning high driving current and serious heat generation.

Hidden Cost-Cutting:

Low-priced modules often use 1.0mm or 1.2mm PCBs—thin enough to flex by hand.

The Consequences:

At internal temperatures approaching 60°C, thin PCBs warp. This causes:

-

Uneven screen surfaces (a “mosaic” effect)

-

Internal copper trace fractures inside the PCB layers

Sostron Solution:

All modules use 1.6mm, four-layer, military-grade PCBs, tested through 1,000 hours of thermal shock cycling in our 4,000 m² R&D center.

Think of it like a building foundation: if it’s thin, collapse is only a matter of time.

2.3 Driver ICs: Refresh Rate vs. Energy Efficiency

Ever see black scan lines when filming an LED screen with your phone? That’s low refresh rate at work.

-

Standard ICs (FM6124, etc.):

-

1920Hz

-

Looks fine to the naked eye, but flickers badly on camera or during sports broadcasts

-

-

High-End ICs (MBI5124 / ICN2038S):

-

3840Hz

-

Ultra-smooth visuals

-

Dynamic energy-saving algorithms

-

For our 10,000-nit Ares series, this reduces power consumption by 20–30%.

Market Generic vs. Sostron Military-Grade Standard

| Core Component | Generic Market Module | Sostron P6 Premium Module | Risk Profile |

|---|---|---|---|

| LED Packaging | Copper wire / iron frame / low-grade epoxy | Gold wire / copper frame / UV-resistant resin | 10× dead pixel rate after 1 year; yellowing causes color shift |

| PCB Process | 1.0–1.2mm, 2-layer | 1.6mm, 4-layer ENIG | Warping and internal trace breakage |

| Potting Process | Manual / semi-auto (air bubbles) | Fully automated vacuum potting | Moisture ingress → PCB corrosion |

| Brightness Decay | >15% at 3,000 hours | <5% at 3,000 hours | Insufficient brightness after 2 years |

3. Business Value Analysis: Why “Cheap” Ends Up Being Expensive

For B2B buyers managing landmark projects—whether Brazilian highways or downtown Cairo—initial CAPEX is only the tip of the iceberg.

The real killer is OPEX.

3.1 The Energy Cost Math

Outdoor P6 screens are power-hungry. Low-quality modules suffer from:

-

Poor power conversion efficiency (~80%)

-

No intelligent energy-saving algorithms

Case Study: 100 m² P6 Outdoor LED Screen, 14 hours/day

-

Generic Screen:

-

400W/m²

-

Annual consumption: 204,400 kWh

-

-

Sostron Ares Series:

-

280W/m² (common-cathode energy-saving tech)

-

Annual consumption: 143,080 kWh

-

At an average industrial electricity rate of $0.15/kWh:

👉 Annual savings: $9,198

👉 Three years of savings can pay for an entire new screen.

3.2 The Maintenance Cost Black Hole

In a southern France outdoor installation (Ares Series), the client stated:

“The screen is mounted 10 meters high. Each repair requires a lift truck and road permits—costing over $1,600 per visit.”

If a cheap P6 module fails quarterly, annual maintenance alone exceeds the initial price difference.

Sostron’s IP65 dual-side potting and 14-year record with zero major failures aren’t selling modules—they’re selling peace of mind.

3-Year Total Cost of Ownership (TCO) – 100 m² P6 Case

| Cost Item | Low-Cost Competitor | Sostron Ares Series | Difference |

|---|---|---|---|

| Initial Purchase | $60,000 | $72,000 | +$12,000 |

| 3-Year Power Cost | $92,000 | $64,400 | –$27,600 |

| Maintenance & Spares | $15,000 | $1,000 | –$14,000 |

| Total 3-Year TCO | $167,000 | $137,400 | Sostron saves $29,600 |

4. Pitfall Avoidance Guide: How Experts Inspect the Truth

With 14 years of manufacturing experience, we welcome informed customers. Here’s how to inspect modules like a pro:

Macro Camera Test

Use your phone’s 5× zoom or macro lens to photograph inside the LED.

-

What to look for:

-

Clear gold wire bonding

-

Transparent LED chips

-

Poor LEDs show rough frames or air bubbles

-

The Smell Test

Smell the back of the module.

-

Red flag:

-

Strong chemical odor = recycled plastic or low-grade coating

-

-

Sostron:

-

Eco-friendly PC + fiberglass housing, flame-retardant, odor-free

-

Weight Test

Place two modules on a scale.

-

Result:

-

Sostron P6 modules are typically 10–15% heavier due to thicker PCBs, full potting, and solid heat sinks

-

5. FAQ: Straight Answers for Procurement Managers

Q: Should I choose P6 or P8 for outdoor projects?

A: It depends on viewing distance.

-

6–20 meters (shopping malls, pedestrian streets): P6 is mandatory

-

50 meters and beyond (highway billboards): P8 or even P10 offers better ROI

Q: Why is your lead time 10 days while others promise 3?

A: Three-day delivery usually means old inventory.

Sostron produces to order, ensuring all modules in one screen come from the same LED bin, guaranteeing color and brightness consistency. Every module undergoes 72 hours of continuous aging tests before shipment.

Q: How do you protect modules during sea freight?

A: Export orders use double-layer flight cases or reinforced wooden crates, with each module individually packed in anti-static bags and shock-absorbing foam.

6. The Sostron Solution: More Than Just Modules

Sostron is not just a module supplier—we operate a 15,000 m² intelligent manufacturing base and are a national high-tech enterprise.

For high-standard outdoor applications, we recommend the Ares Fixed Outdoor Series:

-

All-aluminum cabinets:

-

40% better heat dissipation than steel

-

Operates at 50°C ambient temperature without air conditioning

-

-

Ultra-high brightness:

-

Optional 10,000 nits, built for desert sunlight

-

-

Dual redundancy:

-

Backup power and signal paths—no black screens

-

Beyond hardware, we provide a cloud-based CMS control system, allowing customers in Brazil and Egypt to update content and monitor screen health 1,000 km away—without leaving the office.

Don’t let today’s “savings” become tomorrow’s incident.

👉 Click here to book a live video tour of the Sostron factory

Disclaimer

All market reference prices mentioned in this article are estimates based on supply chain costs and exchange rates at the time of writing and are for budgeting purposes only. Actual transaction prices may vary due to fluctuations in raw material costs (such as LED chips, precious metals, and aluminum), exchange rates, logistics expenses, and specific customization requirements (including irregular shapes or special mounting structures).

Product images and case studies shown are for illustrative purposes only. Sostron reserves the right to upgrade product appearance and technical specifications. Final delivery standards shall be subject to the mutually confirmed technical specifications and contractual agreements.

References: