Table of Contents

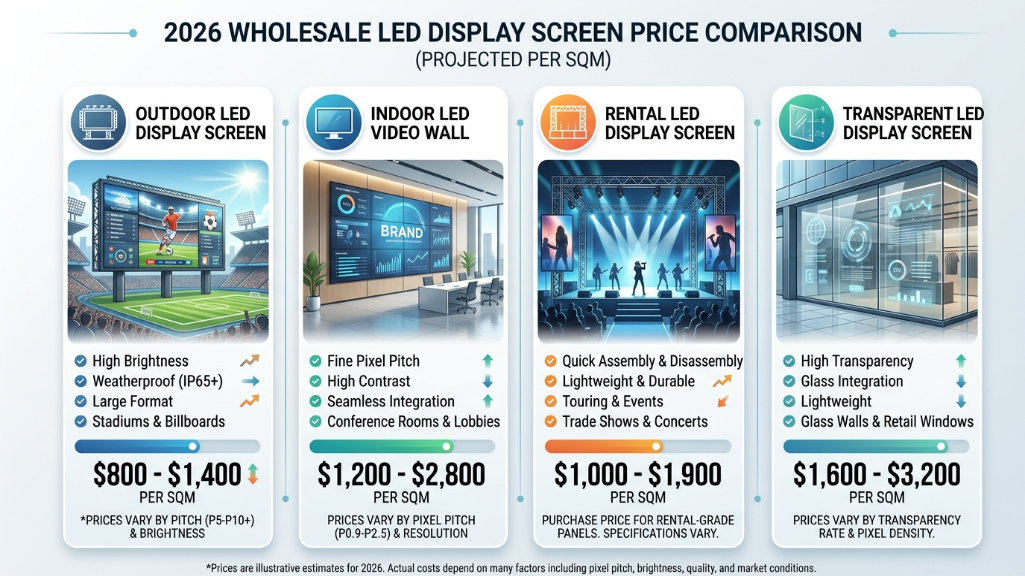

ToggleIn the global market of 2026, the benchmark wholesale price for LED display panels typically ranges from $400/m² to $2,500/m². This price span is primarily influenced by pixel pitch, packaging technology (such as MIP or COB), and weatherproof rating.

For bulk procurement, a factory-direct model usually offers a 15%–25% price advantage over trading intermediaries, along with deeper customization and engineering support.

2026 LED Display Pricing Matrix: What You Need to Know

For performance production buyers, export factory owners, and manufacturing engineers, understanding what truly drives pricing is critical. In 2026, fluctuations in raw material supply chains and the widespread adoption of energy-saving technologies have made pricing structures more transparent—yet more complex.

Below is a reference guide to mainstream wholesale price ranges in today’s market:

| Product Category | Recommended Applications | Pixel Pitch (mm) | 2026 Wholesale Guide Price (USD/m²) | Core Technical Advantages |

|---|---|---|---|---|

| Outdoor Energy-Saving Fixed Installation (Ares 2) | 3D landmark displays, highway billboards | P3.1 – P10 | $650 – $1,200 | Common cathode energy-saving, reduces power consumption by 50% |

| High-End Rental (Carbon Pro) | Touring concerts, product launches | P1.9 – P3.9 | $1,200 – $2,500 | Carbon fiber cabinet, ultra-lightweight at 5KG |

| Indoor Commercial Display (Reta 2) | Conference rooms, luxury retail stores | P1.2 – P1.8 | $800 – $1,800 | 30mm ultra-thin, cable-free design |

| Transparent Display (Crystal) | Glass curtain walls, storefront windows | Based on transparency | $900 – $1,500 | Up to 60% transparency, preserves natural light |

Editor’s Note: Based on our 14 years of global project experience, we’ve observed that 80% of buyers focus only on unit price during the first year. By year three, many realize that maintenance costs for low-quality panels can reach three times the original purchase price.

Why “Cheapest” Is the Most Expensive Choice in 2026

Procurement teams are often under pressure to maximize visual impact within strict budgets. However, as observed in projects ranging from music festivals in Chile to highway installations in Africa, ultra-low-cost panels often come with hidden liabilities:

High Power Consumption

Traditional LED panels can become financially unsustainable amid rising electricity costs in 2026.

Frequent On-Site Maintenance

Low-cost driver ICs frequently cause dead pixels and the notorious “caterpillar effect.”

Compliance Gaps

Displays lacking national high-tech enterprise certification and IP65 double-sided potting protection are extremely vulnerable in harsh weather conditions.

Sostron’s Professional Credentials

As a nationally recognized high-tech enterprise, Sostron operates a 15,000㎡ intelligent manufacturing base and a 4,000㎡ R&D center.

We deliver more than just screens. Through 72-hour rigorous aging tests and our proprietary Ares 2 common cathode energy-saving technology, we help export business owners and engineers maintain wholesale pricing advantages while reducing long-term operating costs by up to 50%.

5 Critical Factors That Dictate Your Wholesale Quote

Pixel Pitch & Resolution (The P-Value Logic)

In LED technology, when pixel pitch is reduced by half, the number of LEDs increases fourfold.

According to 2026 industry data, P2.5 remains the “value champion” of the wholesale market. However, demand for P1.2 in premium conference environments is growing at an annual rate of 35%. Provide you with P2.5 LED screen price and purchasing guide.

The “Heart” of Your Screen: Driver IC & Chip Material

Significant price differences often originate from internal components that buyers rarely see.

-

Gold wire packaging costs approximately 15% more than copper wire, but improves high-temperature stability by 40%.

-

Driver ICs supporting 7680Hz high refresh rates are essential for performance production companies to eliminate camera flicker.

Why Sostron’s Factory-Direct Model Saves You 15%–25%

Within the LED supply chain, each additional distributor layer typically adds 10%–15% to the final cost.

Leveraging its 15,000㎡ manufacturing facility, Sostron eliminates this markup structure.

Economies of Scale in Production

With over 2,000 global projects handled annually, Sostron utilizes fully automated SMT lines to achieve exceptional yield rates.

Material loss is controlled within 0.3%, which directly translates into more competitive wholesale pricing.

R&D-Driven Value: The Ares 2 Example

Our 4,000㎡ R&D center is not just a lab—it’s a cost optimization engine.

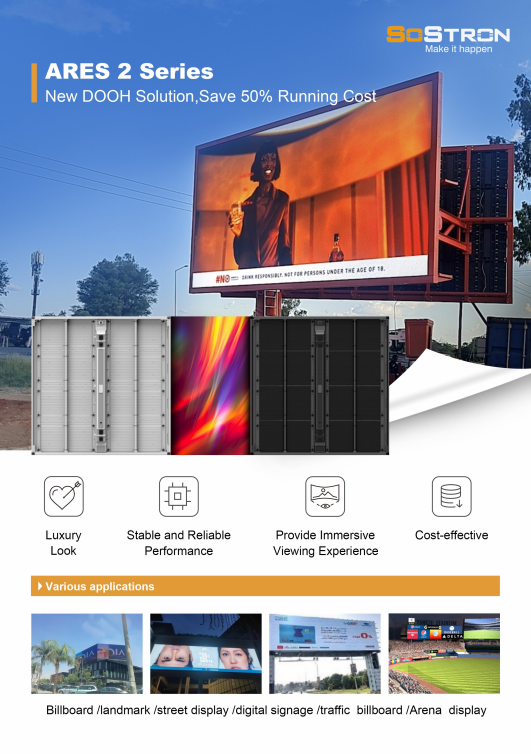

ARES 2 Series (Flagship Energy-Saving Outdoor Solution)

Featuring proprietary common cathode technology, the initial wholesale price is approximately 10% higher than standard displays. However, it reduces operating electricity costs by 50%.

Case Reference:

In an outdoor project in southern France, a client deployed P3.9 Ares Series panels. Given the region’s hot summers and high electricity rates, the display’s superior heat dissipation and low power consumption offset the initial price difference in just 14 months through energy savings alone.

Hidden Costs Most Wholesalers Don’t Tell You

As an experienced editor, I must emphasize:

Panel Price ≠ Landed Price.

An honest wholesale quotation should address the following four dimensions:

Logistics & Duties

Global freight volatility remains in 2026. The Carbon Pro Series, built with carbon fiber cabinets weighing only 5KG per unit, is 40% lighter than traditional die-cast aluminum cabinets—saving approximately 30% in cross-border shipping costs.

Control System & CMS

Many low-cost suppliers exclude sending boxes. Sostron provides integrated hardware-software cloud CMS solutions with fault warning capabilities, reducing on-site troubleshooting labor by 80%.

Installation Structure

Outdoor projects (such as our Brazilian highway installation) require reinforced steel structures. The Storm Pro series adopts a standardized 960x960mm cabinet design with high compatibility, reducing installation time by 25%.

Spare Parts

We provide 3%–5% of total order value in core spare components (modules, power supplies, ICs), ensuring your project never stalls over a single failed LED.

Featured Solutions: Which Series Matches Your Budget?

| Core Need | Recommended Product | Key Edge | Target Audience |

|---|---|---|---|

| Extreme Weight Reduction & Touring | Carbon Pro | Fast-lock design, supports creative configurations | Performance production buyers |

| Long-Term Advertising ROI | ARES 2 Series | IP65 double-sided potting, extended lifespan | Manufacturing engineers |

| Refined Commercial Spaces | Reta 2 | 30mm ultra-thin wall-mount design enhances premium brand image | Export traders / Retail owners |

FAQ: Professional Insights for Bulk Buyers

Q1: Why choose Common Cathode technology in 2026?

Common cathode technology precisely distributes voltage to red, green, and blue LEDs, minimizing heat waste.

This extends panel lifespan and prevents color shift caused by overheating. It is currently the preferred solution for large-scale outdoor wholesale projects.

Q2: Is smaller pixel pitch always better?

Not necessarily. While P1.2 delivers stunning image quality, its unit price can be several times higher than P2.5.

Our recommendation: determine based on optimal viewing distance.

Formula:

Minimum Viewing Distance (m) ≈ Pixel Pitch (mm) × 1

If viewers are 5 meters away, a P5 display delivers significantly better cost performance than P1.2.

Q3: How do you ensure color consistency for bulk orders?

Sostron strictly follows a Single Batch Loading strategy.

For each order, all LEDs come from the same bin classification and undergo 72-hour factory calibration, eliminating the risk of “patchwork screens.”

Conclusion: Start Your Professional Sourcing with Sostron

In the 2026 LED market, getting a quote is easy. Receiving a scientifically engineered display solution is not.

Sostron’s 14 years of industry experience demonstrate that successful projects begin with respect for technical details—not blind pursuit of the lowest price.

If you are preparing for a touring production, commercial real estate LED installation, or industrial-grade display solution, we welcome you to connect with our engineering team.

References:

IHS Markit LED display market forecast

International Electrotechnical Commission (IEC)

About Dylan Lian

Marketing Strategic Director at Sostron