As LED technology engineers, we frequently encounter various types of LEDs in the field of LED development. Among them, Surface Mounted Device (SMD) and Glass Organic Board (GOB) are two common types of LEDs. Although they are both LEDs, there are significant differences in design, application, and performance.

This article will analyze the top 10 differences between SMD and GOB LEDs from the perspective of professional LED technology engineers.

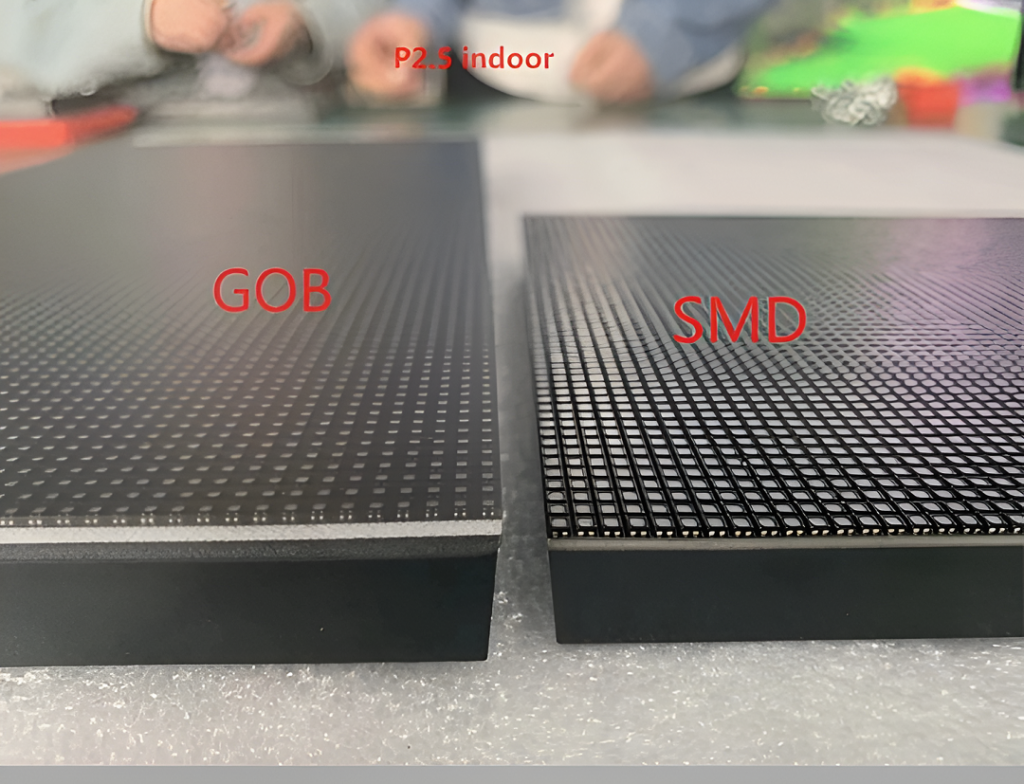

1. Package Structure:

– SMD LEDs use surface mount technology, with LED chips soldered onto a PCB board, resulting in a smaller package size. Take you 5 minutes to learn about SMD LED.

– GOB LEDs are packaged with glass substrates, having larger dimensions and higher thickness, but also being more robust and durable.

2. Chip Layout:

– SMD LEDs are typically arranged in dense arrays on PCB boards, suitable for applications requiring high brightness and uniform illumination.

– GOB LEDs consist of single larger LED chips, suitable for applications requiring higher power and longer-distance projection. Take you to understand LED chips: technology, application and development.

3. Thermal Performance:

– Due to SMD LEDs being packaged on smaller PCB boards, their thermal performance is relatively poorer, requiring additional heat dissipation designs to ensure stable long-term operation.

– GOB LEDs with glass substrates have excellent thermal performance, effectively dissipating heat to the external environment, hence suitable for high-power applications.

4. Optical Performance:

– SMD LEDs have smaller light scattering angles, suitable for applications requiring concentrated light, such as displays and lighting.

– GOB LEDs typically have wider light scattering angles, suitable for applications requiring wide-area illumination, such as outdoor and landscape lighting.

5. Application Scenarios:

– SMD LEDs are commonly used in indoor lighting, electronic product displays, and other scenarios requiring high resolution and brightness.

– GOB LEDs are often used in outdoor billboards, architectural outline lights, and other scenarios requiring long-distance projection and high power output. What is the difference between indoor LED display and outdoor LED display?

6. Manufacturing Cost:

– The manufacturing cost of SMD LEDs is relatively lower, suitable for mass production and cost-sensitive applications.

– The manufacturing cost of GOB LEDs is higher, but in certain high-end applications, their performance and reliability advantages may offset this cost difference.

7. Reliability:

– Due to the lower complexity of SMD LED packaging structure, they generally have higher reliability and longer service life.

– GOB LEDs, with glass substrate packaging, have higher impact resistance and weather resistance, suitable for long-term use in harsh environments.

8. Maintenance and Repair:

– Due to the smaller package structure of SMD LEDs, they are easier to maintain and replace.

– GOB LEDs have larger package structures, requiring more effort and cost for maintenance and replacement.

9. Power Consumption and Efficiency:

– SMD LEDs typically have lower power consumption and higher efficiency, suitable for energy-saving applications.

– GOB LEDs, due to their larger package structure, may have higher power consumption, but can also achieve higher luminous efficiency.

10. Technological Trends:

– With technological advancements, SMD LEDs still have further development opportunities in size reduction, performance improvement, and cost reduction. What is the difference between SMD LED display and COB LED display?

– GOB LEDs have higher potential for development in high-power, high-brightness, and special applications, especially in outdoor lighting and automotive lighting fields.

Choosing SMD or GOB Packaging Technology?

The choice between SMD and GOB packaging technology depends on the specific application scenario. Here are some factors to consider:

– Thermal Requirements: If the project requires high thermal performance, such as stable long-term operation or high-power output, GOB LEDs may have better thermal performance due to their glass substrate packaging.

– Cost Consideration: SMD LEDs usually have lower manufacturing costs, suitable for cost-sensitive projects. While GOB LEDs may be more suitable for high-end projects due to their higher manufacturing costs, especially when their special performance advantages are needed. Here are the commercial LED display price ranges.

– Maintenance and Repair: If the project requires convenience in maintenance and repair, such as frequent LED replacement or high reliability requirements, SMD LEDs may be more suitable due to their smaller package structure, which makes maintenance and replacement easier.

– Application Scenarios: If your project requires high brightness and uniform illumination, such as indoor lighting or displays, SMD LEDs may be the better choice. While if your project requires long-distance projection and high power output, such as outdoor billboards or architectural outline lights, GOB LEDs may be more suitable. Here are examples of outdoor billboards.

Here are some specific application scenario recommendations:

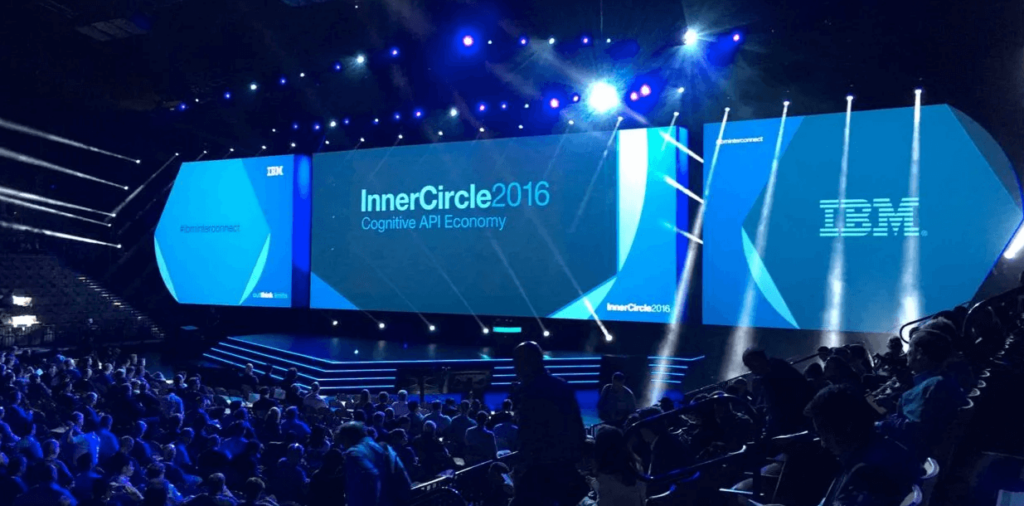

– Indoor Displays: SMD packaging technology is typically chosen due to its low cost and good repairability.

– Outdoor Displays: GOB packaging technology is typically chosen due to its high protection and good thermal performance.

– Small Pixel Pitch Displays: SMD packaging technology is typically chosen for achieving higher pixel density.

– Rental Displays: GOB packaging technology is typically chosen as it can withstand frequent transportation and disassembly.

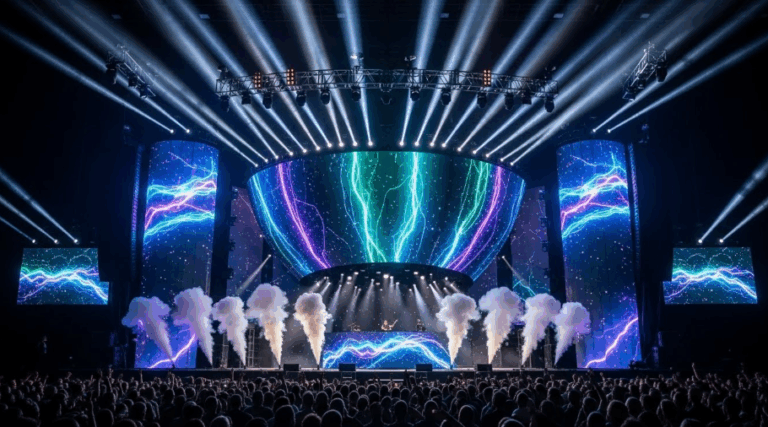

– Stage Displays: GOB packaging technology is typically chosen for its high brightness and contrast.

In conclusion, SMD LEDs and GOB LEDs have distinct differences in packaging structure, application scenarios, performance characteristics, and manufacturing costs. As LED technology engineers, it’s important to consider specific application requirements and performance criteria when selecting LED types to achieve the best performance and cost-effectiveness.