Table of Contents

ToggleExecutive Summary

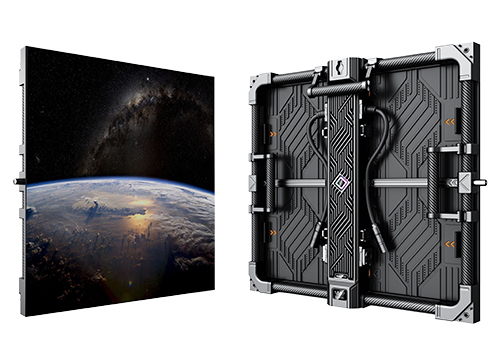

The 500×500 die-cast aluminum rental cabinet has become the backbone of modern live events and temporary display installations. Manufactured from one-piece A380 die-cast aluminum, it delivers an ideal balance of ultra-lightweight design (typically under 8 kg / 17.6 lbs) and military-grade structural strength.

Compared with traditional sheet-metal cabinets, true die-cast aluminum enables genuine front serviceability, micron-level flatness, and fast curved assembly. This makes it the only viable option for touring shows and premium rental applications in today’s high-end event market.

Industry Reality: Why “Low-Cost” Rental Screens Quietly Destroy Your Profits

If you’re a procurement manager at a production company—or an overseas buyer sourcing LED displays—you’ve probably noticed something puzzling:

Why do cheaper cabinets often lead to higher total project costs?

After 14 years in the LED industry, I’ve seen countless cases where saving a few hundred dollars upfront resulted in massive long-term losses. At Sostron’s 15,000 m² intelligent manufacturing base, solving these problems is part of our daily work.

The Three Invisible Profit Killers in the Rental Market

1. The Logistics Cost Black Hole

The biggest expense in rental LED isn’t buying—it’s shipping.

Cabinets weighing over 10 kg (22 lbs) and occupying excessive volume can eat up 30% of your gross margin in freight costs alone.

2. The Labor Setup Trap

Low-precision cabinets require four technicians and three hours just to level and align.

With true one-person handling and fast-lock systems, labor costs drop immediately—and dramatically.

3. The After-Sales Repair Nightmare

Rainstorms during outdoor shows or deformation from transport vibrations can lead to catastrophic failures. These “basic” issues don’t just cost money—they destroy your reputation.

Sostron Insight:

The 500×500 cabinet was engineered specifically to eliminate these three profit drains.

Core Technology Breakdown: Quality Is Decided by “One Piece of Aluminum”

Don’t be fooled by the words “die-cast aluminum” on a spec sheet. The details determine the lifespan of your product.

Material Truth: Virgin Aluminum vs. Recycled Aluminum

Many low-priced cabinets use remelted scrap aluminum. While technically “aluminum,” it contains impurities that reduce tensile strength. Over time, corners crack and flatness deteriorates.

Sostron Standard:

We use A380 virgin aluminum ingots—the same logic used in automotive-grade structural components. The result: zero deformation in drop tests and 20% better heat dissipation.

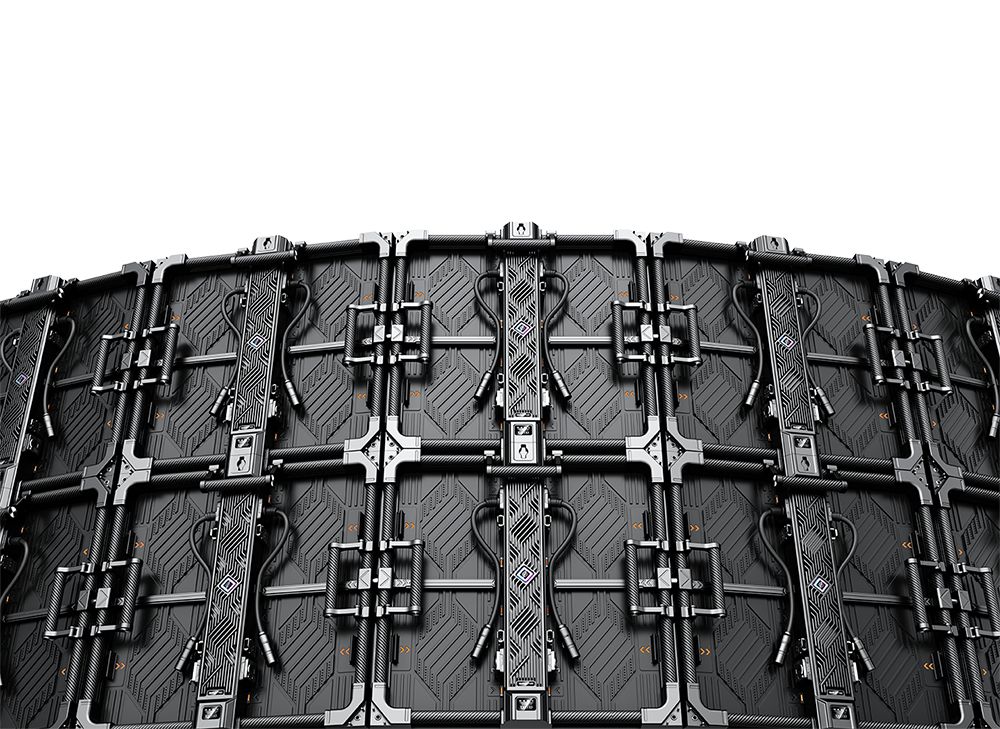

The Physics of a “Rigid” Connection System

What do rental screens fear most?

The dreaded “water ripple” effect—a visibly unstable image caused by cabinet movement.

Technical Explanation:

This happens when cabinet connections lack rigidity. Sostron’s patented Hard Connection System, with four-point positioning, controls inter-cabinet gaps to under 0.1 mm, eliminating physical movement and visual distortion.

Thermal Design: The Line Between Reliability and Failure

LED lifespan is directly tied to operating temperature. Some cabinets save material by thinning the rear shell—bad news for heat management.

Data Speaks:

Sostron cabinets feature large-area heat-dissipation fins and a fully enclosed structure, keeping internal temperatures below 45°C (113°F). Whether under São Paulo’s sun or Shenzhen’s humidity, performance remains stable.

Data Anchor: Sostron 500×500 Selection Guide

To help you match the right product to the right project, here’s a quick-reference matrix covering indoor, outdoor, and creative applications.

Table 1: Sostron 500×500 All-Scenario Application Matrix

1. Setup Project Data

e.g., 1.25, 2.5, 3.9, 4.8

| Series | Pixel Pitch | Cabinet Weight | Service Mode | Applications | Key Advantages |

|---|---|---|---|---|---|

| Hima Indoor Lightweight | P2.6–P3.9 | 5.8 kg | Front / Rear | Studios, launches | Ultra-light, one-hand carry, space-saving |

| Carbon Outdoor Reinforced | P3.9–P4.8 | 5.0 kg | Front service | Outdoor stages, concerts | IP65, rainproof, dustproof, UV-resistant |

| sPad pro2 Curved Series | P2.9–P3.9 | 7.5 kg | Front service | Creative shapes, columns | ±15° angle adjustment, seamless curves |

Business Value: ROI Analysis of High-End Cabinets

Many buyers focus on unit price and ignore Total Cost of Ownership (TCO). Let’s run the numbers over five years, using a 100 m² LED wall as an example.

Table 2: Five-Year Cost Comparison (100 m²)

| Cost Item | Low-End Cabinets | Sostron Die-Cast | Analysis |

|---|---|---|---|

| Initial Purchase | ~$69,500 | ~$90,000 | Sostron +$20,500 |

| Logistics (5 yrs) | High | Low | Save ~$11,000 |

| Installation Labor | High | Low | Save ~$14,000 |

| Maintenance | Very high | Very low (<0.2% failure) | Save ~$17,000 |

| Total 5-Year Cost | $104,000+ | ~$83,000 | Save $21,000+ |

Conclusion:

With Sostron, you’re not buying a metal box—you’re buying a cost-optimized rental supply chain.

Buyer’s Guide: How to Spot “Fake” Die-Cast Aluminum

In B2B procurement, how do you avoid products that look good on paper but fail in reality?

1. Surface Finish Check

-

Real die-cast: smooth, metallic sheen, no pores

-

Fake/low-grade: rough surface, visible burrs or mold lines

2. Sound Test (On-Site)

Tap the cabinet edge with metal.

-

Crisp sound = high-density die-cast aluminum

-

Dull sound = recycled aluminum or welded sheet metal

3. Flatness Verification

Ask for flatness tolerance data.

-

Sostron standard: <0.05 mm

If the supplier avoids the question, consistency is likely manual—and unreliable.

Real-World Performance: Proven Under Extreme Conditions

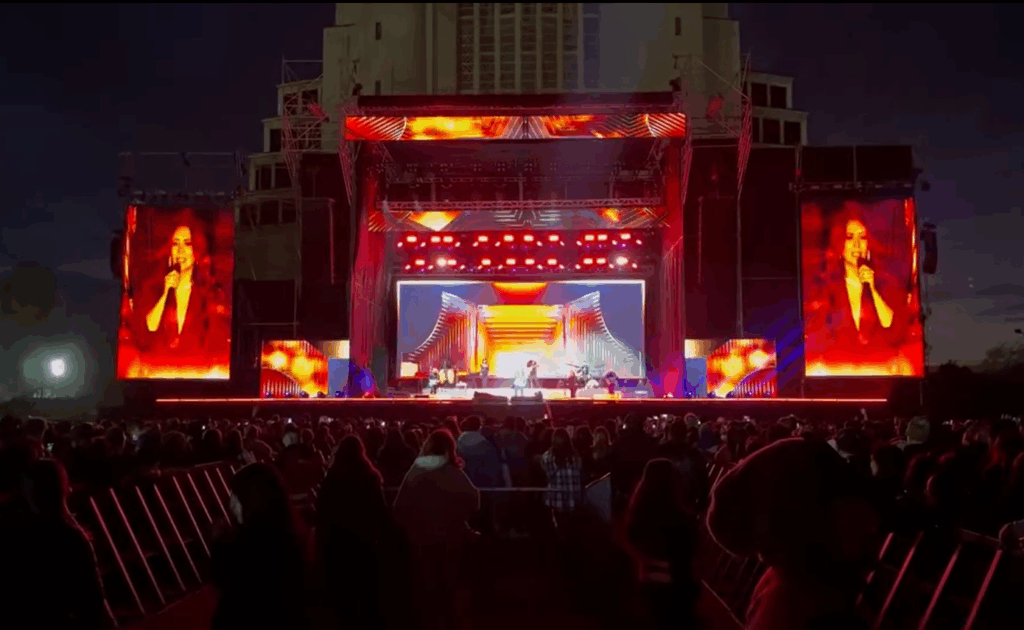

Case 1: Chile Music Festival (Outdoor Rental)

Challenge:

High winds, sand, frequent assembly and disassembly.

Solution:

P4.8 outdoor rental screens using the 500×500 Carbon Series.

Result:

Lightweight cabinets simplified touring logistics. Over three weeks of continuous shows—temperature swings, dust storms, zero failures.

The 3840 Hz refresh rate delivered flicker-free performance for professional cameras.

FAQs (People Also Ask)

Q1: 500×500 or 500×1000—which should I choose?

A: For creative shapes, curves, or weight-sensitive hanging installations, 500×500 offers maximum flexibility. For large flat backdrops where speed matters most, 500×1000 works well. For premium events, Sostron recommends 500×500 due to its higher tolerance and adaptability.

Q2: What IP rating does it have? Can it be used in rain?

A: The outdoor Carbon Series is rated IP65—fully dustproof and resistant to water jets. With proper power-box protection, light rain is not an issue.

Q3: What’s the price range? Is there a minimum order?

A: Pricing depends on pixel pitch and configuration. As a direct manufacturer, we support small trial orders with no MOQ, and offer scalable discounts for volume purchases.

Q4: Warranty and after-sales support?

A: We offer a 3-year full warranty (industry average is 2 years). Each cabinet is tracked via our CRM system. Non-human damage is replaced free during warranty; lifetime technical support follows at material cost only.

The Sostron Solution: Backed by a 15,000 m² Smart Factory

Why partner with Sostron?

-

National High-Tech Enterprise

A 4,000 m² R&D center with salt spray, vibration, and thermal testing labs. -

Flexible Supply Chain

Standard stock with 72-hour fast dispatch, plus full OEM/ODM support—your logo, your standard. -

Global Compliance & Service

Certified with CE, RoHS, FCC, serving clients worldwide.

Conclusion & Call to Action

In the LED rental business, one rule never changes:

Save a little upfront, lose a lot later.

Choosing a premium 500×500 die-cast aluminum rental cabinet means choosing lower costs, higher efficiency, and minimal risk.

Sostron’s 15,000 m² manufacturing base is always open for inspection.

[Get an Accurate Quote]

Submit your size, pixel pitch, and quantity to receive direct factory pricing—no middlemen, no guesswork.

[Book a Factory Visit]

See 14 years of engineering experience in action. We’ll be waiting for you in Shenzhen—ready to explore what’s next together.

Disclaimer:

The market reference prices mentioned in this article are estimates based on supply chain costs and exchange rates at the time of writing and are provided for budgeting purposes only. Actual transaction prices may vary due to fluctuations in raw material costs (such as LED chips, precious metals, and aluminum), changes in exchange rates, logistics expenses, and your specific customization requirements (including non-standard designs or special mounting structures).

The product images and case examples shown are for illustrative purposes only. Sostron reserves the right to upgrade or modify product appearance and technical specifications as part of ongoing product development. Final delivery standards shall be subject to the technical specifications and contractual terms mutually confirmed by both parties.

References:

North American Die Casting Association (NADCA) – Aluminum Alloy A380

IEC 60529 – Ingress Protection Ratings

About Dylan Lian

Marketing Strategic Director at Sostron