Table of Contents

ToggleTable of Contents

A. What is GOB?

B. What is COB?

C. 7 Differences Between GOB and COB

D. Choosing Between COB and GOB Packaging Technology

With the development of LED display technology, GOB and COB packaging technologies have gradually been applied in the LED display field to enhance the protection and display performance of screens. This article provides a detailed analysis of GOB and COB in LED displays and explores the differences between them.

A. What is GOB?

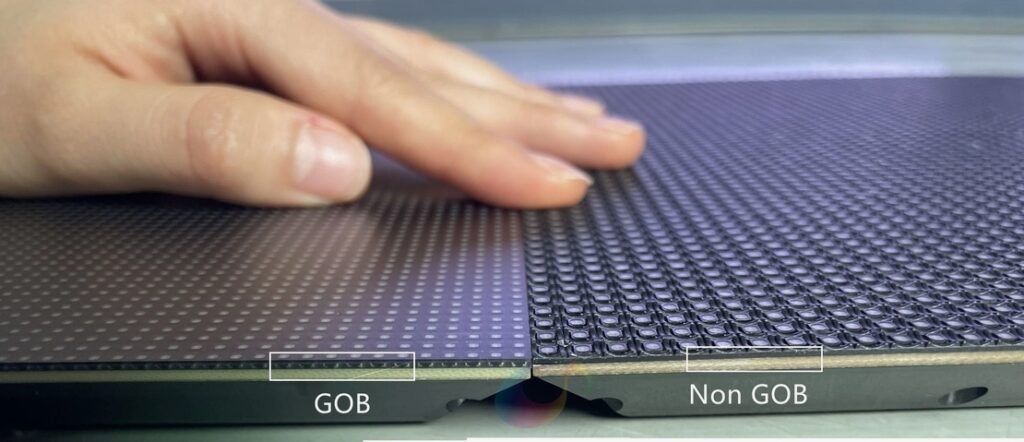

GOB stands for “Glue On Board,” a technology that encapsulates the PCB board and LED beads with optical glue. This technique effectively protects the LED beads from dust, moisture, impact, and other external factors, thereby extending the display’s lifespan. Introducing what is GOB LED screen and what is COB LED screen.

Advantages of GOB technology include:

- High Protection: GOB glue effectively prevents dust, moisture, corrosive gases, and other elements from entering the display, enhancing its protection level.

- Good Heat Dissipation: GOB glue has excellent thermal conductivity, helping to dissipate heat from the LED beads, reducing degradation, and extending lifespan.

- Improved Contrast: GOB glue reduces light reflection, increasing the display’s contrast and color saturation.

- Cost Reduction: GOB technology simplifies the production process, reducing manufacturing costs.

B. What is COB?

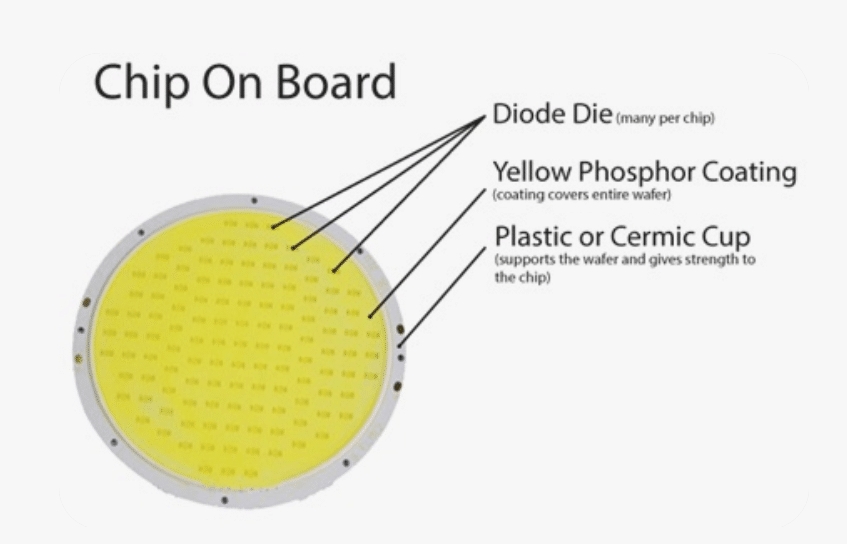

COB stands for “Chip On Board,” a technology that directly mounts LED chips onto the PCB board. COB technology can effectively increase the display’s brightness and contrast while reducing its thickness and weight. COB LED display: exploring novel display technology.

Advantages of COB technology include:

- High Brightness: COB technology increases the light utilization rate of LED beads, thereby increasing display brightness.

- High Contrast: COB technology reduces light reflection, enhancing display contrast.

- Thin Design: COB technology reduces the display’s thickness and weight, making it lighter and thinner.

- High Reliability: COB technology reduces the number of solder points, increasing the display’s reliability.

C. 7 Differences Between GOB and COB

-

Encapsulation Object:

- GOB: Encapsulates the PCB board and LED beads with optical glue.

- COB: Directly mounts LED chips onto the PCB board.

-

Protection Performance:

- GOB: Offers excellent protection, effectively shielding LED beads from dust, moisture, and impact.

- COB: Relatively weaker protection, requiring additional measures to protect the LED chips.

-

Heat Dissipation:

- GOB: GOB glue has good thermal conductivity, aiding in LED bead heat dissipation.

- COB: COB technology has relatively weaker heat dissipation, requiring additional measures to lower LED chip temperature.

-

Brightness:

- GOB: Lower brightness.

- COB: Higher brightness.

-

Contrast:

- GOB: Higher contrast.

- COB: Lower contrast.

-

Cost:

- GOB: Lower cost.

- COB: Higher cost.

-

Application Scenarios:

- GOB technology is suitable for outdoor displays, rental displays, and stage displays requiring high protection.

- COB technology is suitable for indoor displays, small-pitch displays, and high-end displays requiring high brightness and contrast.

D. Choosing Between COB and GOB Packaging Technology

Selecting between COB (Chip-on-Board) and GOB (Glass Organic Board) packaging technology depends on specific application needs and project requirements. Here are some considerations:

- Power Requirements: COB LEDs are typically suitable for high-power applications, as they integrate multiple LED chips in a smaller area, providing higher power output. For projects requiring high-power lighting, such as outdoor or stage lighting, COB technology may be more suitable. Analyzing the top ten differences and selections of SMD and GOB LED for you.

- Light Output Uniformity: COB LEDs offer more uniform light output due to multiple LED chips integrated on the same substrate, ideal for applications requiring uniform illumination, such as commercial and indoor lighting.

- Packaging Structure: COB LEDs integrate multiple LED chips onto a single substrate, simplifying the packaging structure and reducing manufacturing costs while increasing reliability. GOB LEDs encapsulate individual LED chips on a glass substrate, making the packaging structure more complex.

- Heat Dissipation: COB LEDs generate more heat due to multiple integrated chips, necessitating additional cooling designs for stable operation. GOB LEDs, with their glass substrate encapsulation, have better heat dissipation.

- Cost Consideration: COB LEDs generally have lower manufacturing costs due to integrated multiple chips on one substrate, reducing packaging and connection costs. GOB LEDs have higher manufacturing costs due to their complex manufacturing process. Analyzing the 6 differences between SMD LED display and COB LED display for you.

Specific Application Recommendations:

- Indoor Displays: Usually choose COB packaging technology for its lower cost, good heat dissipation, and high contrast.

- Outdoor Displays: Usually choose GOB packaging technology for its high protection.

- Small-Pitch Displays: Usually choose COB packaging technology for higher pixel density.

- Rental Displays: Usually choose GOB packaging technology for durability under frequent handling.

- Stage Displays: Usually choose GOB packaging technology for high brightness and contrast.

Additional Considerations:

- Display Size: For large displays, GOB packaging may be more suitable for better uniformity.

- Brightness Requirements: For high-brightness displays, COB packaging may be more suitable for better heat dissipation.

- Viewing Angle: For wide viewing angles, GOB packaging may be more suitable for reduced light reflection.

Consulting with our technical experts is recommended to get the best advice on choosing between COB and GOB packaging technologies.

Conclusion

In summary, COB and GOB technologies are common packaging techniques in LED display manufacturing, each with unique characteristics and advantages. They play essential roles in different application scenarios. With continuous advancements in LED technology, COB and GOB technologies will continue to be improved and optimized, offering more possibilities for enhancing LED display performance and expanding applications.

About Dylan Lian

Marketing Strategic Director at Sostron