Table of Contents

-

What Determines the Cost of a 4K LED Video Wall

-

Why Resolution Is the Primary Cost Driver

-

Core Technology Breakdown: Understanding the Price Logic

-

Hidden Supply Chain Costs: Avoiding 40% Price Premiums

-

Procurement Pitfalls to Avoid: Three Engineer Rules

-

Industry FAQ: Tackling the Toughest Budget Questions

-

Sostron Solutions: From a 15,000㎡ Production Base to Global Delivery

Understanding the Cost of a 4K LED Video Wall

The total cost of a 4K LED video wall is a comprehensive investment that includes LED modules, control systems, mounting structures, and operational expenses. For mainstream pixel pitches (like P1.2 or P1.5), bare panel prices typically range from $2,000 to $8,000 per square meter. The final cost is directly influenced by pixel density, packaging technology (COB vs. SMD), and driver IC performance.

Resolution and Cost: Do You Really Need 4K?

As an engineer with 20 years of experience, I must clarify a common misconception: 4K is a system-level specification, not just a screen parameter. In the LED world, 4K means 3,840 x 2,160 individually controlled pixels.

Pixel Pitch Effects: If you need 4K resolution on a 5-meter-wide wall, you’ll require a P1.2 product. Using a P2.5 pixel pitch would require a wall width of 10 meters. Halving the pixel pitch quadruples the pixel density, causing costs to rise exponentially.

Physical Resolution vs. Virtual Pixels: Beware of low-cost “4K-compatible” solutions on the market. These usually rely on video processors to scale content. The visual fidelity of such interpolated solutions cannot match native 4K pixel-level quality.

Core Technology Breakdown: The Price Drivers

For quick comparison by event managers and factory owners, here’s a summary:

| Core Dimension | Small-Pitch Indoor (Reta 2) | Stage Rental (Carbon Pro) | High-End Outdoor (Ares 2) |

|---|---|---|---|

| Pixel Pitch | P1.25 / P1.56 / P1.87 | P2.6 / P2.9 / P3.9 | P3.9 / P4.8 / P10 |

| Packaging | GOB / COB (high protection) | SMD (easy maintenance) | Common-cathode energy-saving SMD |

| Refresh Rate | 3,840Hz+ | 7,680Hz (XR-grade) | 3,840Hz |

| Key Advantages | Wireless connection, ultra-thin 30mm | Carbon fiber, ultra-light 5kg/unit | Energy-saving 50%, full aluminum heat dissipation |

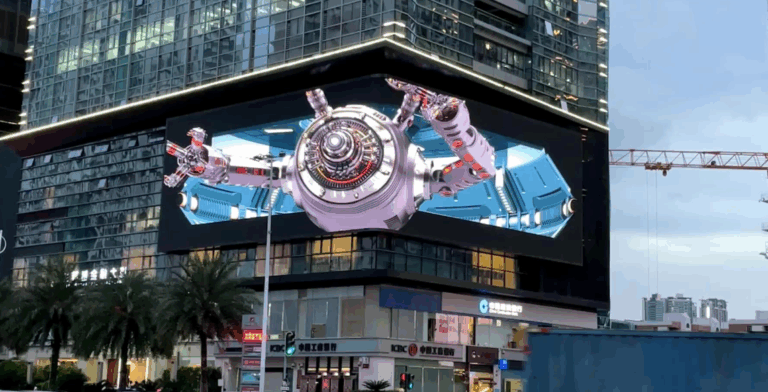

| Target Audience | High-end conference rooms, monitoring centers | Touring shows, concerts, XR shooting | Landmark advertising, 3D naked-eye large screens |

Driver IC Insights (“The Secret Language”):

If your quote mentions “high refresh rate,” confirm the driver IC model. Low-end chips (like standard dual-latch ICs) create scanning lines under camera capture. Advanced PWM driver ICs, like those used in our Hima series, deliver true 16-bit grayscale, ensuring no color banding when filming 4K content.

Commercial Value and Hidden Supply Chain Costs: Avoiding 40% Premiums

Many buyers only look at the “bare panel price” and later face budget overruns. A full lifecycle cost (TCO) analysis looks like this:

| Cost Module | Share of Initial Investment | Key Influencing Factors | Avoidance Tip |

|---|---|---|---|

| LED Panels | 55%-65% | Chip brand (San’an, HC Semitek), gold wire thickness | Don’t just compare prices—confirm chip dimensions |

| Control System | 10%-15% | 4K sending boxes, 10Gb fiber transceivers | Low-end cables cause flicker due to high 4K bandwidth requirements |

| Steel Structure & Installation | 10%-20% | Environment, load-bearing, edge finishing | Indoor projects: choose products like Reta 2 with full front maintenance to save access space |

| Long-Term O&M (5 yrs) | 15%-25% | Spare parts ratio, electricity consumption, repair frequency | Ares common-cathode technology halves power usage, improving long-term ROI |

Expert Procurement Rules: Three Engineer Mandates

-

Verify Spare Parts Ratio: 4K screens have millions of pixels, increasing the chance of failures. Cheap suppliers offer only 1% spares. At Sostron, we require 3%-5% same-batch spares to ensure color consistency over years.

-

Reject Inflated Brightness Claims: Outdoor projects (e.g., Cairo highway installation) need 6,000–10,000 nits to counter direct sunlight. Many vendors overclock indoor LEDs for high brightness, causing over 30% light decay in 12 months.

-

Focus on Thermal Design: High pixel density generates heat. The Carbon Pro series employs thermal simulation to prevent chip failure from heat accumulation.

FAQ: Addressing Key Budget Concerns

Q: Why is your quote higher than online retailers?

A: We operate a 15,000㎡ smart factory with National High-Tech Enterprise certification. Retailers often assemble screens from generic ICs and second-tier chips. Sostron’s 14 years of experience gives us superior supply chain negotiation power and full quality traceability.

Q: Are 4K video walls difficult to maintain?

A: Choose Storm Plus or Reta 2. Both support full front maintenance, allowing module replacement in 5 seconds with a magnetic tool—no need to disassemble the entire wall.

Q: Does energy-saving technology really pay off?

A: With our Ares flagship energy-saving series, common-cathode technology saves 40%-50% per square meter annually. Large-scale outdoor projects typically recover the initial premium in 18–24 months via reduced electricity costs.

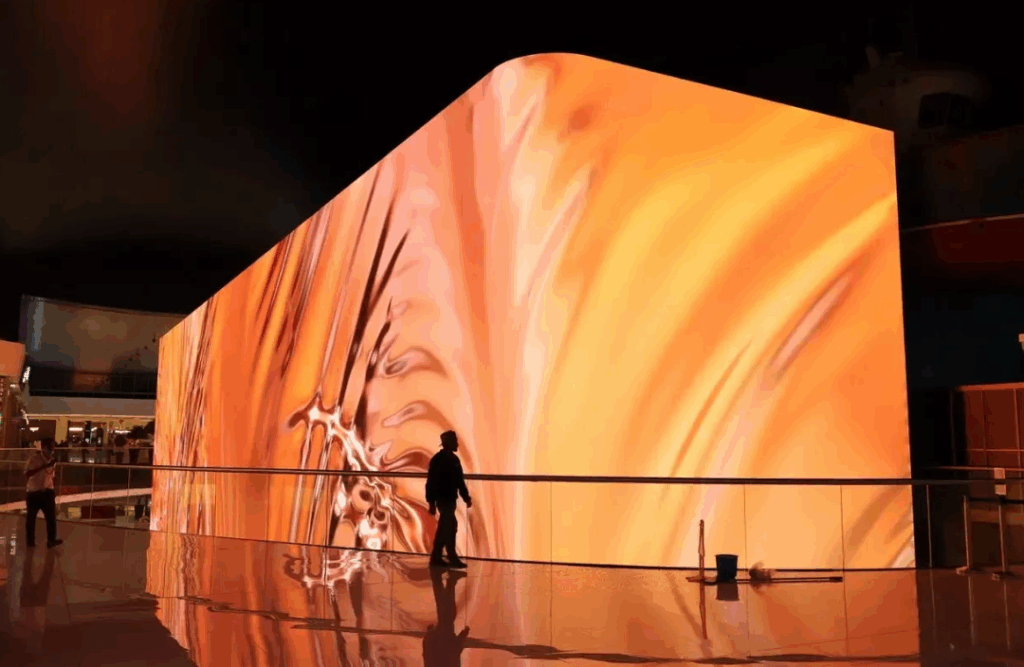

Sostron Solutions: From Factory to Global Projects

We don’t just sell screens—we provide system integration services built on 20 years of industry experience.

-

15,000㎡ Smart Factory: Every 4K module undergoes 72-hour high-temperature aging tests.

Case Study 1: Chile Music Festival (Carbon Family)

In extreme performance environments, our carbon-fiber rental screens with 7,680Hz ultra-high refresh rate delivered zero-flicker, broadcast-grade 4K content.

Case Study 2: Southern France (Ares Series)

High-temperature deployment with full aluminum casing and energy-saving technology maintained 10,000 nits brightness while keeping operational costs minimal.

Conclusion: Making the Right Decision

A 4K LED video wall is a 5–8 year investment, not a one-time purchase. Partnering with manufacturers like Sostron, with a 4,000㎡ R&D center and extensive field experience, helps you avoid 90% of supply chain pitfalls.

Next Step:

Click for a quote: [Contact Sostron for the 4K product pricing]

Disclaimer

The market reference prices mentioned in this article are estimates based on supply chain costs and exchange rates at the time of writing and are provided for budgeting purposes only. Actual transaction prices may vary due to fluctuations in raw material costs (such as LED chips, precious metals, and aluminum), changes in exchange rates, logistics expenses, and your specific customization requirements (including non-standard designs or special mounting structures).

The product images and case examples shown are for illustrative purposes only. Sostron reserves the right to upgrade or modify product appearance and technical specifications as part of ongoing product development. Final delivery standards shall be subject to the technical specifications and contractual terms mutually confirmed by both parties.

References: