Table of Contents

ToggleTable of Contents

-

Definition and Core Advantages of Steel Structure LED Displays

-

Why Choose Steel Structures as the Support for LED Displays?

-

Case Studies: Structural Design Highlights from Successful Projects

-

Key Parameter Analysis

-

Conclusion

Imagine a massive LED screen glowing like a star in the bustling heart of a city, captivating every passerby. Or a crystal-clear giant screen at a live sports event, showcasing every thrilling moment in real time. These stunning visual experiences often owe their reliability and safety to a silent backstage hero — the steel structure. This article delves deep into the technological strengths, industry value, and key considerations when choosing steel structure LED display screens, helping you fully understand their core value.

1. Definition and Core Advantages of Steel Structure LED Displays

A steel structure LED display refers to an LED display system supported by a steel frame, specially designed for large-scale, high-strength, long-term outdoor use. Compared to conventional LED displays, the steel structure version shows remarkable advantages across multiple dimensions.

Why Steel Structures Have Become the Mainstream Choice

| Feature | Traditional Material LED Displays | Steel Structure LED Displays |

|---|---|---|

| Load Capacity | Weaker, limited screen size | Strong, supports thousands of square meters |

| Wind/Earthquake Resistance | Average | Excellent, suitable for high-rise buildings and harsh climates |

| Installation Flexibility | Many structural limitations | High adaptability to various terrains |

| Lifespan | Prone to aging and deformation | Durable for over 20 years |

| Cost | Lower upfront cost | Higher long-term cost-efficiency |

2. Why Choose Steel Structures for LED Displays?

Robust and Durable: Load Capacity and Resistance to Harsh Conditions

Steel structure LED displays typically use high-strength steel (commonly Q235 or Q345) as the mainframe, paired with professional seismic design, making them resistant to typhoons up to level 12 and earthquakes up to magnitude 8. For example, the outdoor LED curtain wall of Shenzhen Ping An Financial Center underwent wind tunnel testing and was proven to withstand instantaneous wind speeds of up to 60 m/s — far beyond the limits of standard aluminum structures.

With a yield strength of 235–345 MPa (2–3 times that of aluminum alloys), steel structures require fewer support points under the same load, allowing for cleaner visual designs. Modern hot-dip galvanizing also enhances corrosion resistance, reaching over 1000 hours in salt spray tests (per ISO 9227 standards).

Flexible Design: Meeting Various Shapes and Sizes

Steel structures offer infinite design possibilities. With computer-aided design (CAD) and finite element analysis (FEA), even complex geometries can be precisely engineered:

-

Curved screens: e.g., Beijing Daxing Airport’s curved display with a 15-meter radius

-

Cylindrical screens: e.g., 360° wraparound display at Dubai Mall

-

Creative-shaped screens: e.g., the wave-shaped artistic display on Shanghai’s Bund

Modular designs also enable easy transportation and on-site assembly. For instance, the circular LED screen at Qatar World Cup’s main stadium was divided into 128 prefabricated modules, assembled in just three weeks.

Excellent Heat Dissipation: Steel’s Contribution to Thermal Management

LED longevity is closely tied to operating temperature. Reducing it by 10°C can double the lifespan (according to Haitz’s Law). Steel’s thermal conductivity (~50 W/m·K) is lower than that of aluminum (160–200 W/m·K), yet:

-

It effectively conducts heat from LED modules to the structure

-

Reduces reliance on active cooling systems, saving energy

-

Maintains stable brightness even in high temperatures

Example: The outdoor LED wall of Tokyo’s Ginza Sony Building employs a specialized steel heat dissipation channel that keeps internal temperatures below 65°C even during 40°C summer heat.

Long-Term ROI: Durability and Maintenance Cost Analysis

While initial investments in steel structure LED displays may be 20–30% higher, their overall lifecycle cost is significantly lower due to superior durability and low maintenance needs.

Let’s compare two hypothetical scenarios:

| Cost Item | Steel Structure LED | Traditional LED |

|---|---|---|

| Initial Cost | $150,000 | $120,000 |

| Annual Maintenance | $7,500 | $18,000 |

| Expected Lifespan | 10 years | 6 years |

| Total 10-Year Cost | $225,000 | $300,000 |

Steel structures reduce pixel failure caused by vibrations, with a 40% lower fault rate compared to traditional setups, minimizing service interruptions.

Note: The above data is illustrative to demonstrate the ROI of steel structure LED displays. Actual costs and returns vary by project. Always request detailed quotes and conduct a comprehensive cost-benefit analysis.

3. Case Studies: Structural Design Highlights

Let’s explore real-world projects where steel structures played a key role:

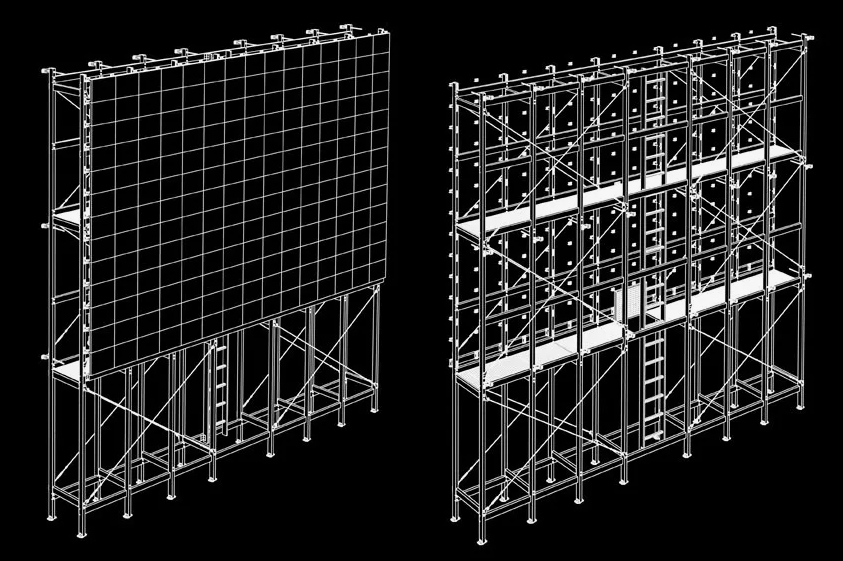

Giant Screens in Commercial Complexes

These displays are often located in windy city centers and require both strength and integration with building design.

Highlight: Spatial truss structures disperse weight, increase wind resistance, and include maintenance pathways. Provide you with the price range of commercial LED displays.

Stadium LED Screens

These massive screens require extreme structural stability, while also factoring in audience viewing angles and aesthetics.

Highlight: Circular or customized steel structures complement stadium architecture, with precise calculations for angle and height to ensure optimal visibility.

Outdoor Advertising Tower Screens

Placed on city landmarks, they must withstand weather and offer visual impact.

Highlight: Tall steel pillars ensure stability and wind resistance, with exterior design matching the advertising theme. Provide you with a complete guide to outdoor LED display prices, purchase and application guides.

Highway Information LED Screens

These displays provide crucial traffic info and must operate reliably in all weather.

Highlight: Rugged steel frames resist high-speed wind turbulence from passing vehicles, with anti-corrosion coatings to extend lifespan.

4. Key Parameter Analysis

-

Pixel Pitch: e.g., P4, P6, P10 — determines resolution and viewing distance

-

P10: best for distances over 10m

-

P4: suitable for fine displays within 5m

-

-

Brightness (nit): For outdoor use, ≥5500nit recommended to combat sunlight glare

-

Energy Efficiency: Opt for displays with auto-brightness adjustment and energy-saving chips

Vendor Evaluation Criteria

-

Certifications: ISO9001, CE, RoHS — indicators of professional quality

-

After-Sales Support: Annual structural inspection, cleaning, module replacement, etc.

Cost Control Tips

-

For long-term use: Purchasing is more cost-effective

-

For temporary events: Consider renting, such as for concerts or expos

5. Conclusion

Why Are Steel Structures Indispensable in Large LED Projects?

As we’ve seen, steel structures offer unmatched stability, flexibility, and durability, forming the foundation for reliable LED screen performance and diverse applications. Whether for commercial displays, sports events, outdoor ads, or traffic signs, steel frameworks are essential for structural safety and design realization.

How to Make Your LED Display Project Safer and More Impressive?

Choosing an experienced, technically proficient LED display supplier is critical. A capable vendor provides not only quality LED products but also tailored, safe, and aesthetic steel structure solutions based on your specific needs. Share your ideas, listen to professional advice — and your LED project is sure to be safer, more brilliant, and more successful!

About Dylan Lian

Marketing Strategic Director at Sostron