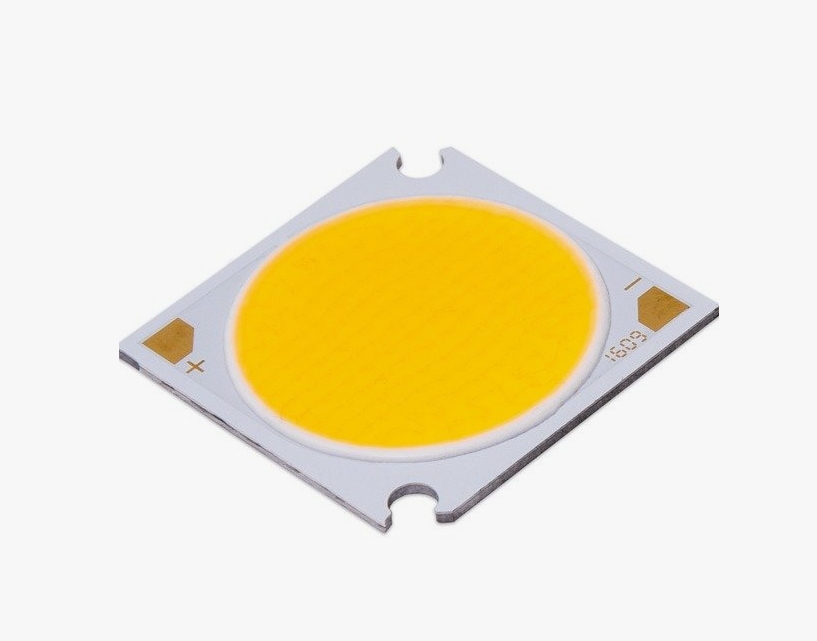

As LED display technology continues to advance, several types of LED technologies have emerged in the market, including the traditional SMD (Surface-Mounted Device), the emerging COB (Chip on Board) technology, and the intermediary GOB (Glue on Board) technology. Each of these technologies offers unique advantages and is suitable for different application scenarios. This article will provide a detailed comparison of these three technologies based on the provided content and analyze the criteria for choosing them in practical applications.

1. Pixel Density and Resolution

COB technology supports pixel pitches smaller than 1mm, allowing for higher packaging density, resulting in greater pixel density, resolution, and better color uniformity. In contrast, SMD and GOB typically support pixel pitches larger than 1mm, with lower packaging density. However, improvements in SMD technology have significantly enhanced these aspects. What is a fine pitch LED display?

2. Color Uniformity

COB LED displays, due to the close arrangement of LED chips, achieve better color uniformity. SMD and GOB LED displays may experience slightly lower color uniformity due to larger pixel sizes caused by individual encapsulation, although technological advancements have notably improved these aspects. Introducing LED chips: technology, applications and development.

3. Brightness

COB LED displays generally have higher brightness potential, especially at small pixel pitches. SMD and GOB LED displays, on the other hand, usually offer higher brightness potential at larger pixel pitches, making them more suitable for outdoor applications.

4. Viewing Angle

COB LED displays typically offer a wider viewing angle due to the proximity of LED chips. SMD and GOB LED displays may have a narrower viewing angle, but with modern improvements in SMD technology, high-quality SMD and GOB LED displays can also provide a wide viewing angle.

5. Image Quality

COB LED displays feature enhanced image quality thanks to their high packaging density and improved color uniformity. GOB technology significantly improves contrast, reduces glare, lowers visual fatigue, and enhances overall image quality by covering the entire surface of the SMD LED display module with transparent glue, turning granular pixels into a flat plane.

6. Thickness

COB LED displays can be thinner than SMD and GOB displays, as COB LEDs are directly and precisely mounted on the PCB, saving a significant amount of design space.

7. Seamless Design

SMD and GOB LED displays typically have small gaps or black matrices between individual LEDs. In contrast, COB LED displays, with their uniform design, eliminate gaps between modules, providing a continuous display effect.

8. Heat Dissipation

COB LEDs offer superior heat dissipation because mounting LED chips directly onto the substrate allows for more efficient thermal management. SMD and GOB LEDs may require additional cooling solutions in certain applications.

9. Scalability

SMD and GOB LED modules have an advantage in scalability over COB modules due to their smaller size and individually encapsulated LEDs, allowing for flexible module arrangements.

10. Design Flexibility

SMD and GOB LED displays offer greater design flexibility because their modular design allows for the creation of more complex and imaginative designs.

11. Assembly and Maintenance

COB LED modules are relatively easy to assemble, but if a failure occurs, the entire module may need to be replaced. SMD and GOB LED modules require more careful assembly, but if a failure occurs, individual LEDs can be replaced, which may be more cost-effective and efficient. Can LED displays be repaired?

12. Energy Efficiency

SMD and GOB LEDs are known for their lower power consumption and higher energy efficiency. However, COB LEDs can also provide excellent energy efficiency in indoor applications, especially considering their high brightness output.

13. Reliability and Durability

COB LED modules are less susceptible to damage from shock and vibration due to their unified structure and lack of individual casings. GOB LED modules, with transparent glue covering the entire module surface, provide a highly protected LED display.

14. Failure Rate

Traditional SMD and GOB LED displays tend to have a higher dead pixel rate, while COB LED displays eliminate the risk of pixel drop-off during soldering as they do not require reflow soldering.

15. Cost and Maintenance

COB LED displays are more expensive than SMD and GOB displays. When a failure or damage occurs, repairing or replacing individual LED chips in COB displays can be challenging.

When choosing between SMD, COB, or GOB LED display technologies, consider the following factors:

Determine the Application Scenario:

- For outdoor applications requiring high brightness and a wide viewing angle, SMD or COB technology might be more suitable.

- For indoor applications where brightness is not the primary concern, but color uniformity and pixel density are critical, COB technology could be the better choice.

Evaluate Image Quality Requirements:

- If high resolution and color uniformity are necessary, COB technology, with its high packaging density, may be the best option.

- If the demands for image quality are not as stringent, SMD or GOB technology are also viable choices.

Consider Design Requirements:

- If the project requires a high degree of design flexibility and scalability, the modular design of SMD and GOB might be more appropriate.

- If the design demands seamless images and a unified appearance, COB technology, due to its seamless design features, may better meet these needs. Here is a comprehensive guide to curved LED displays.

Budget Evaluation:

- If the budget is limited, SMD and GOB technologies may offer a cost advantage, especially for large-scale projects.

- If the budget is sufficient, COB technology could be considered, as it may offer better performance and longer lifespan in certain applications, despite its higher cost.

Maintenance and Operating Costs:

- Assess the maintenance and replacement costs in long-term operations. COB technology may require less maintenance, but repairs can be more expensive when needed.

- SMD and GOB technologies might offer more flexibility in maintenance, with the replacement of individual LEDs being more economical. Are LED billboards expensive? How much are the running costs?

Conclusion

Each of the SMD, COB, and GOB LED displays has its own advantages, and the choice of technology depends on the specific requirements and preferences of the target application. SMD and GOB LEDs excel where design flexibility is crucial, while COB LEDs are the best choice for applications requiring seamless images and ideal viewing angles. Additionally, SMD and GOB offer advantages in overall project costs, including production and maintenance. As technology continues to evolve, we can expect these LED display technologies to see broader applications and higher performance in the future.