Table of Contents

ToggleTable of Contents

1. Definitions and Characteristics of CSP and COB LED Chips

2. Differences Between CSP (Chip Scale Package) and COB (Chip on Board)

3. Specific Comparison of CSP and COB LED Chips

4. Advantages and Disadvantages of CSP and COB LED Chips

5. Choosing Between CSP and COB Chips?

With the continuous development of LED technology, two new LED chip packaging technologies, CSP and COB, have gradually emerged. CSP and COB chips both have characteristics such as small size, good heat dissipation, and high efficiency, and have been widely used in LED displays, lighting fixtures, and other fields. So, what are the differences between CSP and COB chips? What is COB LED screen?

1. Definitions and Characteristics of CSP and COB LED Chips

CSP (Chip Scale Package): This is a technology that directly encapsulates LED chips on a PCB without the need for brackets and soldering, hence having characteristics such as small size, good heat dissipation, and high efficiency.

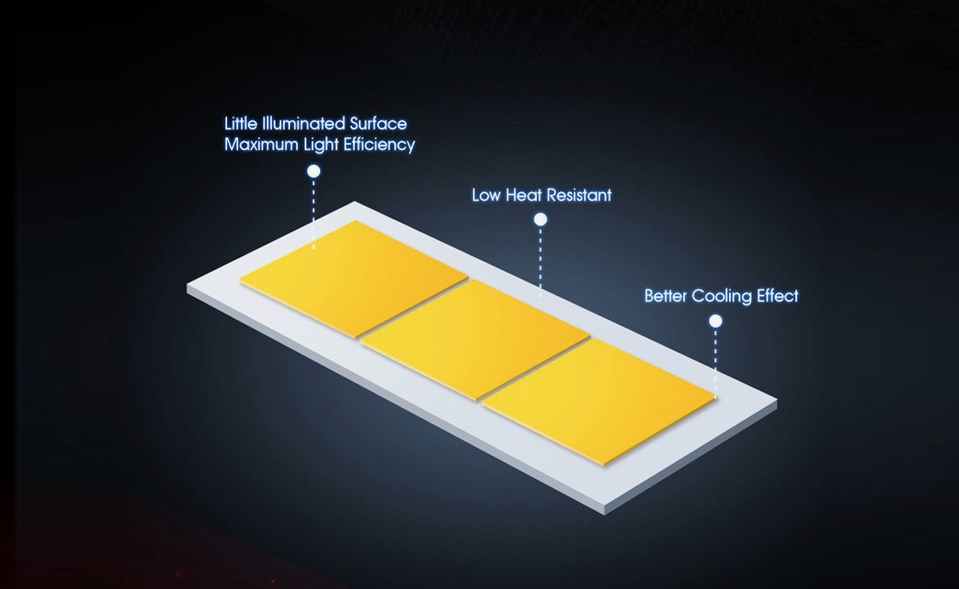

COB (Chip On Board): This is a technology that directly encapsulates LED chips on a PCB and covers them with glue or silicone gel, without the need for brackets, hence having characteristics such as small size, low cost, and high reliability. Is COB LED better than LED?

2. Differences Between CSP (Chip Scale Package) and COB (Chip on Board)

a. Packaging Method

CSP: CSP uses chip-level packaging technology to directly encapsulate LED chips on the surface of wafers and connect them to PCBs through soldering or other methods. This packaging method achieves high integration, allowing CSP LED chips to occupy less space on smaller PCBs.

COB: COB fixes LED chips directly on circuit boards and electrically connects them through linear or nonlinear connections. This packaging method is relatively simple but has lower integration than CSP. What is the difference between SMD LED display and COB LED display?

b. Size and Integration

CSP: CSP has smaller size and higher integration. The size of CSP chips is usually only a few millimeters, allowing for complex functions such as multi-layer packaging and multi-chip connections.

COB: COB has larger size and lower integration. The size of COB chips is usually several centimeters or more, making it difficult to achieve complex functions.

c. Performance Characteristics

CSP: CSP LED chips have excellent electrical and thermal characteristics, good heat dissipation performance, and can improve product stability and reliability. At the same time, CSP LED chips are lightweight, energy-efficient, and suitable for portable electronic products.

COB: COB LED chips have high stability, simple processing, and relatively low cost advantages. However, their heat dissipation performance may not be as good as CSP, so attention should be paid to heat dissipation issues during use.

d. Application Scenarios

CSP: CSP LED chips are suitable for high-performance, small-sized products such as portable electronic products and high-end displays due to their high integration, excellent electrical and thermal characteristics, and small size.

COB: COB LED chips are more suitable for products requiring high reliability, high durability, and simple circuit board design, such as large displays and commercial displays, due to their stability and low cost advantages. Here are the commercial LED display price ranges.

3. Specific Comparison of CSP and COB LED Chips

| Feature | CSP | COB |

| Packaging Method | Chip Scale | Chip on Board |

| Size | Smaller | Larger |

| Integration | Higher | Lower |

| Heat Dissipation | Better | Worse |

| Optical Performance | Better | Worse |

| Cost | Higher | Lower |

| Application Scenarios | High-end displays, backlight modules | Ordinary displays, lighting fixtures |

4. Advantages and Disadvantages of CSP and COB LED Chips

CSP:

Advantages: Small size, good heat dissipation, high efficiency

Disadvantages: Higher cost

COB:

Advantages: Lower cost, high reliability

Disadvantages: Slightly lower efficiency

5. Choosing Between CSP and COB Chips?

When choosing between CSP and COB chips, the following factors need to be considered:

Size and Weight: CSP is usually smaller and lighter than COB, suitable for applications with limited space, while COB may be more suitable for applications with less stringent packaging size requirements.

Cost: COB usually has lower packaging costs than CSP because it does not require additional packaging shells. If cost is a key consideration, COB may be more competitive.

Thermal Management: Since CSP packaging is usually smaller, heat dissipation may be a challenge. If your application requires high performance and generates a lot of heat, COB, which can better dissipate heat, may be considered.

Reliability: The reliability of CSP and COB packaging depends on the application environment and manufacturing quality. COB technology may be affected by vibration and mechanical stress because the chip is directly connected to the PCB, while CSP packaging usually includes protective layers that can provide better mechanical protection.

Electrical Performance: COB usually provides shorter signal paths, so it may have advantages in high-speed circuit design. However, CSP packaging may be easier to layout and have better high-frequency characteristics.

Manufacturing and Assembly: COB usually requires more assembly processes because the chip is directly connected to the PCB, while CSP packaging is similar to traditional packaging and may be easier to handle in manufacturing and assembly.

Supply Chain and Technical Support: Finally, factors such as supply chain and technical support should also be considered. Your supplier may be better at providing one packaging technology than another, or may have more confidence in the reliability and performance of one technology.

In summary, CSP and COB LED chips each have their own advantages, and the choice of packaging technology depends on the requirements of the application scenario. For applications requiring high heat dissipation, high optical performance, high integration, and high reliability, CSP is the preferred choice; while for cost-sensitive applications, COB is the more economical choice. In the future, with further development of LED technology, CSP and COB LED chip packaging technologies will continue to improve to meet the needs of different application scenarios.

About Dylan Lian

Marketing Strategic Director at Sostron