Table of Contents

ToggleTable of contents

1.Packaging method

2. Display effect

3. Stability and maintainability

4. Energy consumption and cost

5.Application scenarios

6. Price

7.Typical application cases

8. Comparative cases

9. User evaluation cases

As LED display technology continues to advance, SMD LED displays and COB LED displays have become mainstream products in the market. Each type of display has its advantages and is suitable for different applications. This article compares SMD LED displays and COB LED displays in six aspects to help readers make informed decisions when choosing the right product for their needs.

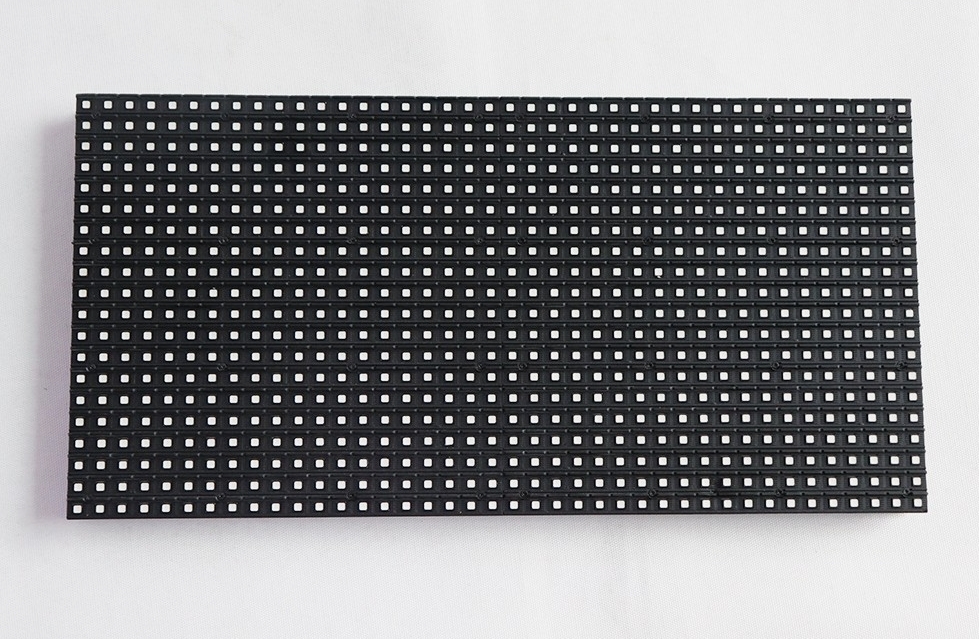

1. Packaging Method:

SMD (Surface Mounted Device) technology, also known as surface mount technology, involves packaging LED chips into individual bulbs, which are then soldered onto a PCB (Printed Circuit Board). This packaging method is widely used in LED displays, especially in most outdoor displays. Take you 5 minutes to learn about SMD LED.

COB (Chip On Board) technology involves directly soldering LED chips onto a PCB without the need for brackets and reflow soldering. This packaging method simplifies the packaging process, making the product thinner and allowing for smaller pixel pitches. COB LED display: Explore novel display technology.

2. Display Performance

Due to the physical gaps between SMD technology’s LED bulbs, there may be a certain level of granularity in the display, especially when viewed up close. In contrast, COB technology provides a better overall visual experience with more vibrant colors and superior detail, making it more suitable for extended close-range viewing.

COB screens generally have higher contrast compared to SMD screens, and when viewed head-on, the display effect of COB screens is closer to that of LCD screens. However, it’s important to note that, due to the inability to selectively sort individual bulbs for similar optical performance in COB screens, color deviation may occur when viewed from an angle.

3. Stability and Maintenance

SMD technology LED screens have overall weaker protection, making them susceptible to damage and reduced performance in terms of waterproofing, moisture resistance, and dust protection. However, their structural characteristics make on-site repairs relatively convenient, facilitating later maintenance.

COB technology LED screens offer better overall protection, achieving an IP65 front protection rating and allowing for cleaning with a wet cloth. Nevertheless, due to the characteristics of their packaging method, if an issue arises, COB screens may require factory repairs, making on-site repairs impossible. Take you 5 minutes to understand LED IP levels.

4. Power Consumption and Cost

Mainstream SMD screen bulbs often use positive assembly processes, with lead wires obstructing the light source, resulting in relatively higher power consumption for the same brightness.

COB screens mostly use inverted assembly processes, where the light source is unobstructed, leading to lower power consumption and better economic efficiency. However, due to the complexity of COB technology, manufacturing costs are usually higher than those of SMD technology.

5. Application Scenarios

SMD LED Display: Due to its lower manufacturing cost, SMD displays are suitable for large-scale production and application, especially in large display scenarios such as outdoor billboards and sports stadiums. Stadium LED display: enhance event experience and excitement.

COB LED Display: Because of its outstanding display performance and stability, COB displays are typically used in high-end display scenarios such as premium meeting rooms and command centers, where extended close-range viewing is required. Take you 5 minutes to understand the conference room LED display.

6. Pricing

SMD: Due to its advantages, such as high automation, small size, and uniform light emission, SMD-packaged LED displays are generally more expensive. This is suitable for scenarios with high requirements for display performance and reliability.

COB: Although COB technology solves the problem of high-density packaging, its relatively simplified production process results in lower costs. Therefore, COB-packaged LED displays are usually more economically viable, making them suitable for mid-to-high-end markets, especially for cost-sensitive projects. Here are the commercial LED display price ranges.

7. Typical Application Cases

Outdoor Advertising: SMD LED displays, with advantages like low cost and wide viewing angles, are suitable for outdoor scenarios such as billboards and large building displays. For example, the giant LED display screens in Times Square, New York, utilize SMD LED display technology.

Indoor Displays: COB LED displays, with their fine display effects and high brightness, are suitable for indoor scenarios like meeting rooms, shopping malls, and exhibition halls. For instance, the National Convention Center in Beijing employs COB LED display technology.

Stage Performances: SMD LED displays, known for their fine display effects and vibrant colors, are suitable for stage backgrounds and lighting effects. For example, the stage of the U.S. Spring Festival Gala uses SMD LED display technology.

8. Comparison Case

Outdoor Advertising: A certain shopping mall conducted a comparison between SMD LED displays and COB LED displays on outdoor billboards. The results showed that COB LED displays had a more delicate display effect with a wider viewing angle, but they also came at a higher cost. SMD LED displays, on the other hand, had a lower cost but a slightly inferior display effect compared to COB LED displays.

9. User Reviews

User A: Having used both SMD LED displays and COB LED displays, I find that COB LED displays offer better display performance, but they also come at a higher price. If I prioritize display quality, I would choose COB LED displays; if I prioritize cost-effectiveness, I would choose SMD LED displays.

User B: I’ve used SMD LED displays, and overall, they offer great value for money with high brightness. Although the display effect is slightly inferior to COB LED displays, for indoor use, SMD LED displays are more than sufficient.

In conclusion, SMD LED displays and COB LED displays exhibit significant differences in packaging methods, display performance, stability and maintenance, power consumption and cost. SMD technology is widely used outdoors, while COB is more suitable for indoor environments with high image quality requirements. When choosing an LED display, users should consider their specific needs and budget. If high display performance is a priority, SMD LED displays are the better choice; if cost-effectiveness is a priority, COB LED displays are more economically viable. With continuous technological advancements, both technologies are evolving to meet various market demands.

About Dylan Lian

Marketing Strategic Director at Sostron