Table of Contents

ToggleTable of Contents

-

A New Era of Display Technology

-

Carbon Fiber Materials: The “Black Gold” of the 21st Century

-

Why Carbon Fiber LEDs Are the New Trend in Display Technology

-

Four Core Advantages of Carbon Fiber LED Display Screens

-

Multi-Industry Application Scenarios

-

Frequently Asked Questions

-

Conclusion and Actionable Recommendations

1. A New Era of Display Technology

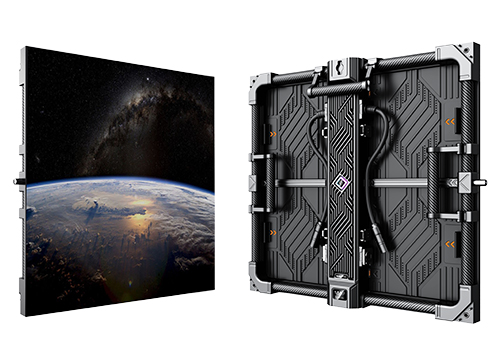

In today’s digital age, LED display screens have become the core medium for information dissemination and visual presentation. With breakthroughs in material science, a revolutionary display solution is changing the industry landscape — Carbon Fiber LED Displays. This innovative product, which combines advanced materials with display technology, not only redefines the performance standards of displays but also offers unprecedented possibilities for various application scenarios. From massive billboards in Times Square to dynamic displays at World Cup stadiums, carbon fiber LED displays are gaining global favor with their unique advantages.

2. Carbon Fiber Materials: The “Black Gold” of the 21st Century

Carbon fiber, hailed as the “King of New Materials,” is an advanced composite material made of fibers containing more than 90% carbon. It is five times stronger than steel, yet only a quarter of its weight, making it the material of choice for aerospace, high-end automobiles, and sports equipment. The unique molecular structure of carbon fiber grants it a series of extraordinary properties:

-

Ultra-High Strength and Rigidity: Carbon atoms are arranged in a crystalline form, with tensile strength in the fiber direction exceeding 5000 MPa.

-

Outstanding Corrosion Resistance: It exhibits strong resistance to corrosion from acids, alkalis, and salt fog, far surpassing traditional metal materials.

-

Excellent Thermal Stability: The coefficient of thermal expansion is extremely low, and performance is virtually unaffected in the temperature range of -50°C to 150°C.

-

Electromagnetic Shielding Properties: Naturally possesses electromagnetic interference (EMI) shielding capabilities, making it ideal for protecting sensitive electronic devices.

When this cutting-edge material meets LED display technology, it gives birth to the “super product” in the display field — the Carbon Fiber LED Display, which perfectly solves many of the pain points of traditional metal-structured displays.

3. Why Carbon Fiber LEDs Are the New Trend in Display Technology

The reason carbon fiber LED displays have become the new trend in modern display technology is primarily because they meet the current market’s challenges for lightweight, durable, and efficient displays. Compared to traditional aluminum alloy or steel-frame displays, carbon fiber LED displays have not only the advantage of lighter weight but also superior structural toughness, enabling them to withstand higher external pressure.

As advertising and information display scenarios diversify, there is an increasing demand for ease of installation and maintenance, durability, and the ability to adapt to various environments. Carbon fiber LED displays precisely meet these needs, making them the preferred choice for various application scenarios.

The rise of carbon fiber LED displays is a direct response to these challenges. According to a Global Market Insights report, the global carbon fiber market surpassed 4 billion USD in 2022, with an annual growth rate of 18.7% in the electronics sector. This growth trend reflects the strong demand for lightweight, high-performance materials in the industry.

Practically, carbon fiber LED displays address several key issues:

-

Transportation and Installation Costs: Traditional large LED screens can weigh 30-50 kg per square meter, while carbon fiber versions reduce the weight by 40%-60%.

-

Outdoor Durability: The corrosion issue of metal structures in coastal and high-pollution environments is fundamentally resolved.

-

Dynamic Use Scenarios: For temporary events and touring performances, which require frequent assembly and disassembly, carbon fiber LED displays offer better solutions.

A typical case is the carbon fiber LED ring screen at the Tokyo Olympics main venue. With a circumference of over 400 meters, this massive display achieved the same visual effect as traditional materials but with only one-third of the weight, greatly reducing the load on the roof structure while enduring the test of high temperatures and rainy weather in the summer.

4. Four Core Advantages of Carbon Fiber LED Display Screens

a. Revolutionary Breakthrough in Lightweight Design

Weight has always been a critical factor limiting the application of LED display screens. The introduction of carbon fiber material has completely changed this situation:

-

Weight Reduction of 40%-60%: A typical carbon fiber LED screen weighs only 15-25 kg per square meter, while traditional aluminum products typically weigh 35-50 kg.

-

Simplified Structure: The high-strength properties allow for reduced support structures, further reducing the overall weight.

-

Savings on Transportation Costs: For a 20-square-meter screen, the carbon fiber version can reduce the transportation weight by approximately 500 kg, significantly lowering logistics costs.

A practical case from an advertising company in Shenzhen in 2023 shows that when installing a 200-square-meter LED advertising screen on the exterior wall of a commercial center with a carbon fiber structure:

-

Installation time was reduced from 3 days to 1.5 days.

-

Overall installation costs decreased by 35%.

-

Building load evaluation costs were saved by around 200,000 RMB.

b. Exceptional Durability: Redefining Product Lifespan

The physical properties of carbon fiber bring a qualitative leap to LED display screens:

-

Impact Resistance: The fracture toughness of carbon fiber is more than twice that of aluminum alloy, effectively resisting accidental impacts like hail.

-

Fatigue Resistance: Carbon fiber maintains structural stability far beyond metal materials in repeated disassembly and vibration environments.

-

Corrosion Resistance: Completely unaffected by rain, salt fog, industrial waste gases, etc., making it especially suitable for coastal and heavy industrial areas.

In Texas, USA, a sports stadium replaced its LED scoreboard in 2024 with a carbon fiber LED model, which endured several extreme weather conditions, including a tennis ball-sized hailstorm. Post-examination showed only minor scratches on the screen’s surface, while 12% of the modules in the traditional displays installed at the same time had to be replaced.

c. Climate Change Resistance: All-Weather Display Solution

Outdoor displays face the greatest challenge in coping with harsh weather conditions. Carbon fiber LED displays perform excellently in this regard:

-

Water Resistance: Carbon fiber itself does not absorb water, and when combined with special sealing techniques, it achieves an IP67 protection rating.

-

Wind Resistance: The lightweight design reduces wind load, while the high strength ensures structural stability.

-

Temperature Adaptability: With an operating temperature range of -40°C to +85°C, it is suitable for climates ranging from polar to desert.

In 2023, a carbon fiber LED sky screen installed at a shopping mall in Dubai withstood temperatures of 50°C in summer and sandstorms, resulting in an 82% reduction in failure rates compared to previous models.

d. Quick Installation and Maintenance: A New Standard for Efficiency

The modular design and lightweight nature offer installation advantages:

-

One-Person Operation: Most carbon fiber LED modules are designed to be handled and installed by a single person.

-

Tool-Free Assembly/Disassembly: Magnetic or quick-lock structures allow for module replacements in minutes.

-

Front and Rear Maintenance: Ultra-thin design allows for maintenance operations from both the front and rear of the screen.

A theater in London’s West End used carbon fiber LED for its stage backdrop, allowing the entire backdrop to be replaced in 2 hours, while traditional systems required 6-8 hours, providing great flexibility for performance scheduling.

5. Multi-Industry Application Scenarios Analysis

a. Outdoor Advertising: A New Dimension of Urban Visuals

In the outdoor advertising sector, the lightweight and durable nature of carbon fiber LED displays undoubtedly provides advertisers with greater flexibility. Many cities use these displays in high-rise buildings, subway stations, and bus stops because they can withstand various environmental challenges. Moreover, the wind resistance of carbon fiber material ensures that displays remain stable even during strong winds, preventing interruptions in the advertising content.

b. Sports Events and Performances: Reliable Performance in Extreme Environments

Sports events and performance venues often require large-scale displays to showcase real-time data and event footage. Carbon fiber LED displays, with their outstanding durability and impact resistance, have become the ideal choice for sports arenas and stages.

For instance, during the 2022 FIFA World Cup in Qatar, multiple stadiums used carbon fiber LED displays that could withstand extreme weather and high-intensity audience usage.

c. Transportation and Public Facilities: A Reliable Information Hub

In critical infrastructure, the demand for stable displays is high. Carbon fiber LED displays are widely used in transportation and public facilities, especially in subways, train stations, and airports. Their superior wind, waterproof, and high-temperature stability ensures that these displays maintain long-term stable operations, providing timely information to passengers. Function and application of LED video walls at transportation hubs.

For example, during the 2023 terminal renovation project at Hong Kong International Airport, carbon fiber LED flight information screens maintained 24/7 operations while reducing maintenance frequency from once a month to once per quarter.

d. Commercial Retail and Exhibitions: The Art of Balancing Space and Display Effectiveness

In commercial retail environments, the high-efficiency display capability and space-saving advantages of carbon fiber LED displays are widely utilized in malls, shopping centers, and exhibitions. Through stunning visual effects, businesses can attract more customers and enhance brand image. The lightweight nature of carbon fiber also allows for more flexible display screen placement, maximizing display space. There are price ranges for commercial LED displays here.

Apple has gradually adopted carbon fiber LED display walls in its global flagship stores, reducing the thickness from the traditional 300mm to 120mm and saving about 30% on transportation and installation costs annually.

6. Frequently Asked Questions

a. Is the price of carbon fiber LED displays significantly higher than traditional products?

The initial procurement cost is indeed 20%-30% higher, but the total lifecycle cost (TCO) is usually lower. For a 10-year usage period, transportation, installation, and maintenance costs can be reduced by 30%-50%. As production volumes increase, the price gap is rapidly narrowing.

b. Does the carbon fiber material affect the heat dissipation performance of the display?

The thermal conductivity of carbon fiber is comparable to that of aluminum alloys. Additionally, modern carbon fiber LED screens are designed with special thermal channels. Tests by Samsung show that their carbon fiber modules maintain a temperature 3-5°C lower than traditional modules after running for 72 hours.

c. Are carbon fiber LED screens prone to scratches that affect visual quality?

Commercial-grade carbon fiber LED screens undergo special hardening treatments, with a Mohs hardness rating of 7H or higher (similar to smartphone screens). Outdoor tests by LG show that after two years of wind and rain exposure, the surface gloss retention is over 95%.

d. How can I determine the quality of a carbon fiber LED screen?

Key factors to consider are three certifications: (1) Material certification from TORAY or MITSUBISHI, (2) Structural safety certification (CE or UL), and (3) Display performance certification (ISO 12664). Quality products typically offer a 10-year material warranty.

e. How environmentally friendly is the recycling of carbon fiber LED screens?

Modern carbon fiber recycling technology is well-established. Toray Industries’ recycling process allows for the reuse of more than 85% of the material. Compared to aluminum displays, carbon fiber screens can reduce carbon emissions by approximately 40% over their lifecycle.

7. Conclusion and Action Recommendations

Carbon fiber LED displays represent the future of display technology. They perfectly address the limitations of traditional products in terms of weight, durability, and environmental adaptability. Currently in a rapid growth phase, businesses with the following characteristics should prioritize adoption:

-

Scenarios where frequent content or location changes are required, such as pop-up stores or touring exhibitions.

-

Installation environments with weight constraints, such as historic buildings or glass curtain walls.

-

Areas with high corrosion or extreme climates, such as coastal cities, industrial zones, or cold regions.

-

Projects sensitive to total lifecycle costs, such as long-term operational transportation hubs or sports venues.

For users planning to deploy display solutions between 2025-2026, we recommend:

-

Prioritize evaluating carbon fiber options: Even if not ultimately adopted, include them in the comparison range.

-

Focus on modularity: Choose designs that support front and rear maintenance and tool-free assembly.

-

Verify material sourcing: Ensure the use of carbon fiber materials from top brands like Toray (Japan) or Hexcel (USA).

-

Consider future scalability: Choose systems compatible with both new and old modules to protect long-term investments.

As manufacturing processes mature and economies of scale come into play, carbon fiber LED displays are transitioning from a high-end option to a mainstream choice. Adopting them now not only provides immediate performance benefits but will continue to offer durability and low-maintenance advantages over the next 5-10 years. The next leap in display technology has arrived—are you ready?

References:

About Dylan Lian

Marketing Strategic Director at Sostron