Table of Contents

TogglePeople may know few things about COB LED display, but probably didn’t hear the new pixel protection technology, GOB LED display. Let’s introduce for you now.

What’s GOB LED screen technology?

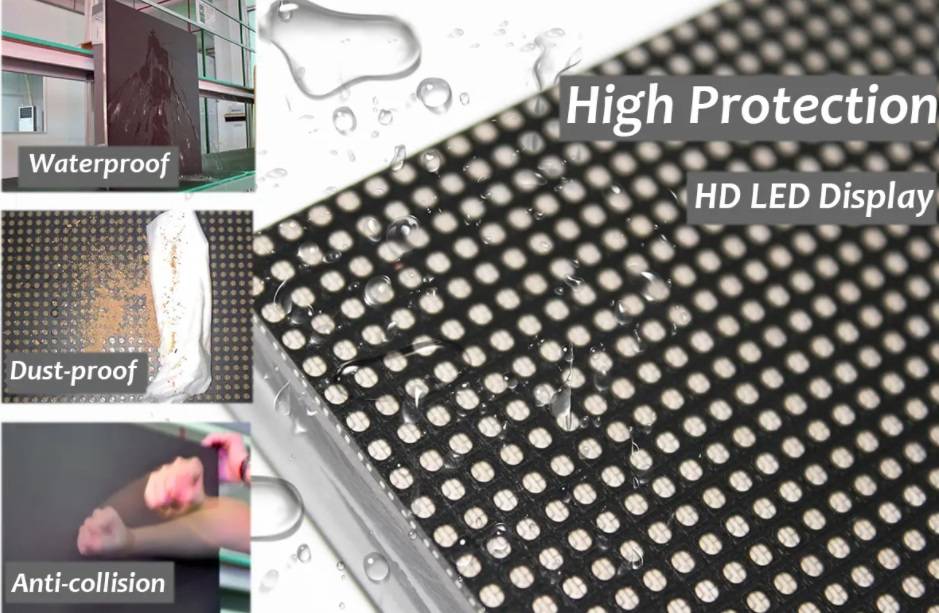

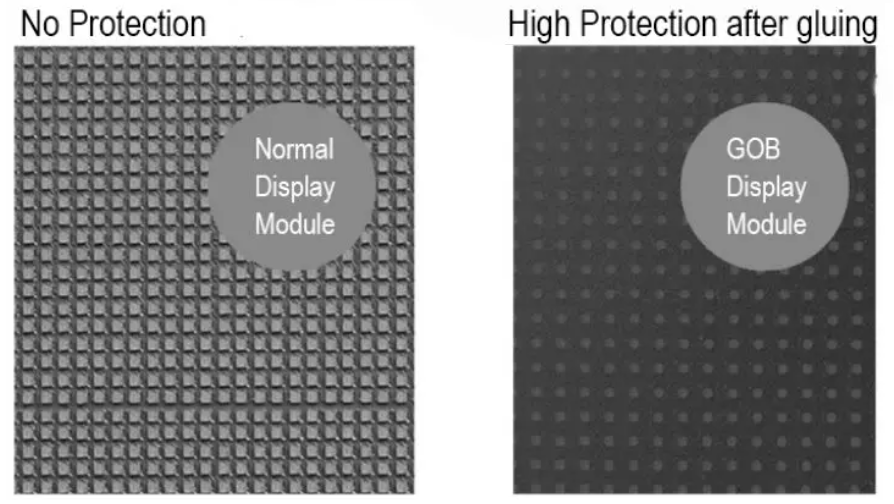

GOB is Glue on board to get high protection led display, which is new technology, an analogy as module encapsulation. It is working on the whole display module, e.g. 250*250mm, by using a patented transparent glue covering the surface of module’s PCB board already with thousands SMD lamps soldered on it, finally the module getting the special shield on its surface.

It comes out a high protection led display capable for anti-collision (anti-bump), dust-proof, waterproof, anti-moisture, anti-UV, along with no harmful impact for heat dissipation and brightness loss. The long time strict test clarified that the shield-glue even contributes the heat dissipation, extending the life span.

The revolution change to push the whole led display industry is that this GOB display is aimed for the fine pitch led display and rental screens, which have natural demands for led diodes protection.

What’s COB LED screen technology?

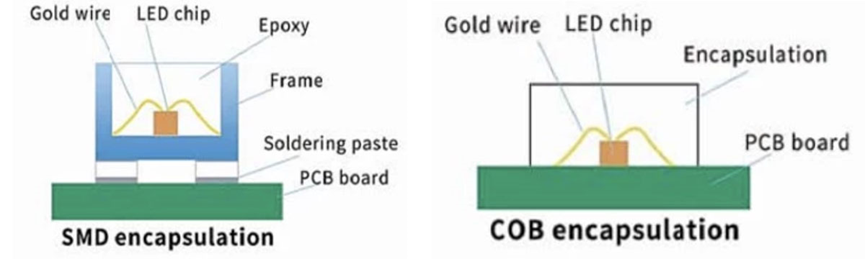

COB is Chip on board, which is a different chip encapsulation technology, all chips directly integrated packaged on the special PCB board, while what we said encapsulation tech is putting three RGB led chips to integrate inside an SMD electronics package to produce the individual SMD diodes.

COB literally sounds similar to the GOB display technology, but it has longer developing history, and they are different.

Wide viewing angle, high color uniformity, high contrast,high power efficiency, etc, are the cliches features same with traditional led technology. The biggest thing is using COB to get high protection performance like collision avoidance ,moisture proof and dust proof,in short, higher environmental adaptability.

What’s the difference between GOB and COB?

Obviously, COB technology is also to get high protection display same with GOB.

Besides the cost, COB has a risky during the process of wavelength and color splitting and picking for all chips on the boards, which make it difficult to get perfect color uniformity for whole display. But GOB can get good color uniformity as modules have been made and tested in traditional way same as normal modules before the special gluing. The maintenance for COB is also a problem waiting to be solved.

GOB,COB are mainly used to form large format size HD indoor displays over 80inches, while the main application of Micro, Mini LED display is currently expected to be used less than 80 inches in consumer market, like smartphones, wearable handsets, virtual reality products, television,etc.

SOSTRON as a leading solution-based large size led display manufacturer located in Shenzhen, the developing and manufacturing center of high end led displays.

We devotes to using new technology to rich the display lines and giving more value to our clients to help them win big reputation. SOSTRON GOB technology-based rental and small pitch led display series is delivering to our clients, and accepting new inquiries for special requirements for high protection display.

About Dylan Lian

Marketing Strategic Director at Sostron