Table of Contents

ToggleLEDs are a type of light bulb that have come into popularity due to their efficiency, environmentally friendly nature, and long lifespan. When used commercially in digital signs and scoreboards, LED diodes have the ability to improve the light quality, durability, and cost of the sign.

There are many different types of LEDs but most used for LED display is DIP and SMD for the last 20 years. Although they are slightly similar in mechanics (they’re both energy efficient light sources that are used in conjunction to make one big illumination), they are quite different in makeup, rendering them better suited for two different applications.

We’d like to explain the main differences between DIP & SMD LEDs and how they are best used. Do you understand the difference between SMD LED display and COB LED display?

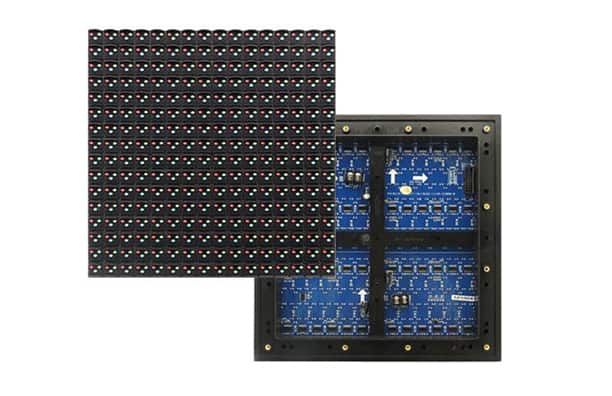

DIP (Dual Inline Package)

DIP LEDs or dual in-line packages are constructed to resemble a traditional light bulb, with a single colour per component. A red, green, and blue bulb are joined together to create an endless possibility of colours. A fourth white one can also sometimes be added for additional variety and brightness. These bulbs have a low lumen output, at about 4 per LED.

The small triad of bulbs are pieced together to create the large intended display image. As such, bulbs can be seen within the screen and have a high pixel pitch. DIPs are usually made durably, making them resistant to weather and able to withstand hard conditions. Due to the limitations of their visibility, and weather-resistant design DIP bulbs are often used on outdoor signs.

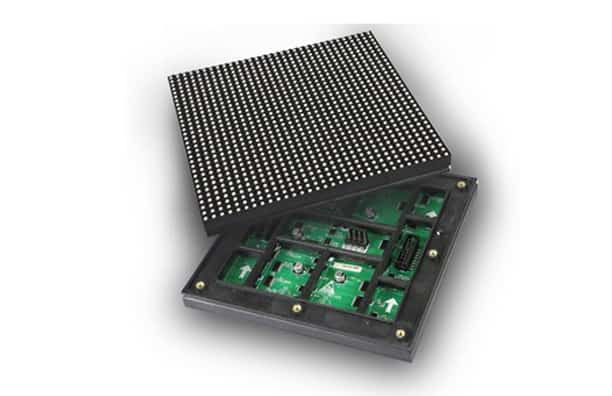

SMD (Surface Mount Diode)

SMD LEDs or surface mount diodes are lightweight LEDs built inside of an enclosed case that is commonly used in a variety of screens and devices on the market. They are small in design offering a ton of versatility in their use and screen configuration and offering a low pixel pitch. These types of LEDs are a popular choice due to their energy efficiency, long lifespan.

As an improved design from traditional LEDs, SMDs offers a high lumen output of about 50 to 100 lumens per watt. They can be extremely bright with crisp output, clear images, and true to colour nature. Not only are SMDs a cost-effective choice, they offer superior quality for close viewing, high resolutions and bright images, making them great for indoor signs and screens. Do you know the difference between indoor LED display and outdoor LED display?

What’s the difference?

LED packaging technology:

SMD displays use surface mount LED packaging technology, and the LED chips are directly mounted on the surface of the LED module. This makes SMD LEDs thinner, lighter, and have a wider viewing angle.

The DIP display screen uses dual in-line packaging technology. The LED chip is inserted into the hole of the module through the pins and then welded. This makes DIP LEDs larger and thicker in packaging.

Brightness and visibility:

Since the LED chips of SMD displays are directly on the module surface and the LED light source is closer to the audience, SMD displays usually have higher brightness and wider viewing angles. This enables SMD displays to provide excellent visibility in both indoor and outdoor applications.

DIP displays are usually used in indoor applications due to their packaging characteristics, while outdoor applications may require more light sources to achieve sufficient brightness.

Resolution and image quality:

SMD displays typically have higher resolution and better image quality because the LED chips can be packed closer together, allowing for finer pixel pitches. This makes SMD screens suitable for applications requiring high resolution and image detail, such as indoor LED video walls.

DIP displays typically have larger pixel pitches and relatively lower resolutions, making them suitable for less demanding applications such as billboards.

Maintenance and serviceability:

SMD displays are generally easier to maintain because the LED modules are easier to replace and don’t require much soldering work.

Maintenance of DIP displays can be more challenging because replacing LED modules involves complex soldering work.

Durability:

Because DIP displays have relatively larger LED packages, they may in some cases be more durable and able to handle harsh weather and physical damage.

SMD displays are more fragile and require additional protective measures to ensure long-term reliability.

Overall, SMDs are a newer, more improved LED design that makes them capable of offering high-quality resolution and crisp, bright signs. Being a newer technology SMDs are much smaller in size than DIP’s, with a superior colour output. They are a more common choice when it comes to digital screens not only due to their capabilities but also their efficiency and lifespan. Typically, SMD displays are more suitable for indoor and outdoor applications, while DIP displays may be more suitable for special environments and large billboards. Do you know the current price of outdoor LED displays?

DIPs are a reliable choice if outdoor signs are your goal, due to their weather-resistant nature. Compared to incandescent bulbs these LEDs are still energy efficient and of a preferred quality.

Regardless of which type ultimately make up your scoreboard or display or digital sign, LEDs are a great environmentally and cost-friendly option that your patrons will enjoy.

About Dylan Lian

Marketing Strategic Director at Sostron