Table of Contents

ToggleWhat Is a Stadium LED Display?

A stadium LED display is a broadcast-grade visual system engineered specifically for sports venues. Unlike standard outdoor advertising billboards, stadium displays must meet far stricter requirements:

-

Ultra-high refresh rate (≥3840Hz) to support HD and slow-motion broadcast cameras

-

Soft masks and anti-collision padding to protect athletes

-

Dual power and dual signal redundancy to guarantee uninterrupted live broadcasts

Common applications include perimeter LED displays, center-hung scoreboards, and ribbon boards.

As a Supply Chain Director at Sostron with over 20 years of experience reviewing thousands of Bills of Materials (BOMs), I can tell you this:

the real difference between a $400/m² screen and an $800/m² screen is rarely brightness. It’s the manufacturing decisions hidden behind the PCB that determine whether a display lasts one season—or five years.

If you’re a procurement manager for a production company or a system integrator, this guide will help you avoid low-price traps and understand what truly makes a stadium LED display reliable from the supply-chain level.

Engineering Scenarios: It’s Not Just a “Big TV”

The complexity of stadium environments lies in the fact that one venue requires multiple display technologies. Chasing a “one-size-fits-all” solution is a common reason projects fail final acceptance.

1. Perimeter LED Displays

This is the most physically demanding application.

Impact Resistance

Soccer balls can exceed 100 km/h (62 mph) on impact. In this scenario, Sostron’s Storm Pro Series is equipped with:

-

Custom rubber louvers

-

Soft top-edge impact cushions

These are not only to protect the screen, but to prevent athlete injuries, a requirement aligned with FIFA safety standards.

Adjustable Viewing Angle

To ensure optimal camera and audience visibility, cabinets must include 60°–90° adjustable rear support brackets.

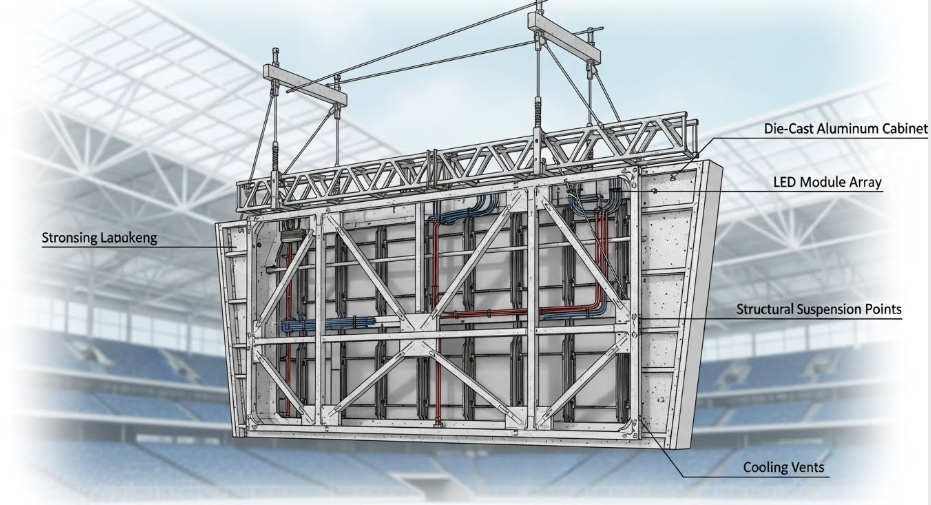

2. Center-Hung Scoreboards

Suspended above the court, the primary challenge here is weight.

Every additional 1 metric ton of screen weight can increase roof steel structure costs by tens of thousands of dollars.

Our Recommendation

-

Die-cast magnesium alloy cabinets, reducing weight by over 40% compared to traditional steel

-

For indoor arenas, the Reta 2 fine-pitch series is often used for high-detail zones due to its ultra-thin design and seamless assembly

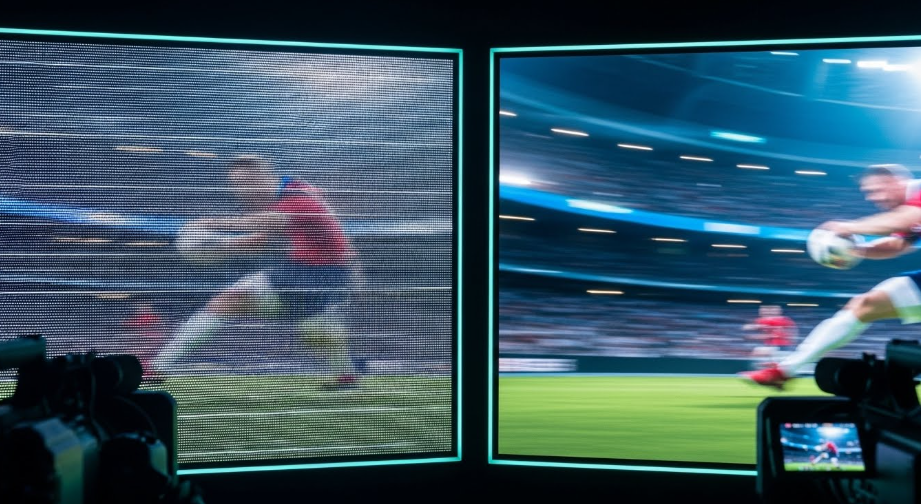

3. Broadcast-Critical Image Quality: Refresh Rate

This is the parameter buyers are most often misled on.

Human Eye vs. Camera Lens

-

1920Hz may look fine to spectators

-

But at 1000fps slow-motion replay, low-refresh displays produce visible black scan lines

Sostron Standard

-

Minimum 3840Hz for all sports projects

-

High-end deployments reach 7680Hz, such as our Carbon Pro Series used at a major Chilean music festival, fully supporting 4K broadcast production

Technical Selection by Application Scenario

| Application | Recommended Series | Pixel Pitch | Brightness | Key Features |

|---|---|---|---|---|

| Perimeter Displays | Storm Pro (IP65) | P8 / P10 | >6500 nits | Soft mask, adjustable brackets, dual-side IP65 potting |

| Center Scoreboards | Reta 2 / Storm Plus | P2.5 / P3.91 | >1200 nits | Lightweight die-cast aluminum/magnesium, 360° curved assembly |

| Ribbon Boards | ARES 2 (Energy-Saving) | P10 | >7000 nits | Narrow maintenance space, full front access, common-cathode design |

💡 Expert Tip

For open-air stadiums, always evaluate wind load calculations. The Storm Pro cabinet design has passed Category 12 typhoon simulation tests, a critical factor for coastal venues.

Supply Chain Reality: The Hidden Cost You Don’t See on Spec Sheets

Factory owners often ask me:

“Why is your quote 15% higher than competitors?”

The real question is: Are you buying a screen for one year—or five?

Hidden costs usually surface right after the warranty expires.

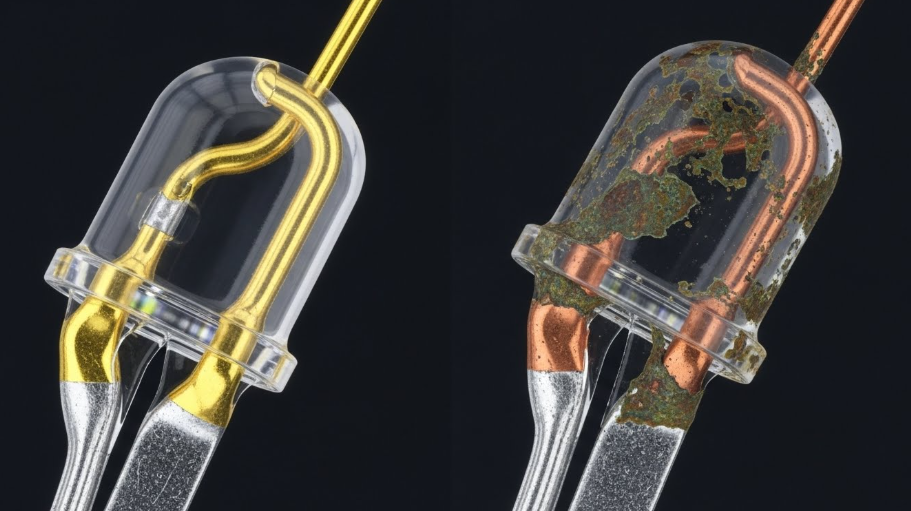

1. LED Packaging: Gold Wire vs. Copper Wire

This is the industry’s biggest unspoken shortcut.

Copper Wire LEDs

-

Lower cost

-

Vulnerable to oxidation and electrochemical corrosion in humid or coastal environments

-

Result: dead pixels and “caterpillar effects” after ~18 months

Sostron Standard

For all outdoor stadium projects (Storm Pro, ARES 2), we specify:

-

Nationstar gold-wire LEDs or

-

Custom high-reflectivity copper brackets

Gold’s chemical stability is what lets you sleep at night.

2. True Redundancy Means More Than Two Power Supplies

Loop Signal Backup is non-negotiable for live sports.

-

Standard daisy-chain wiring means one failed module can black out everything downstream

-

Sostron uses a loop topology

If the main signal cable is damaged—say, kicked during a match—the system detects the failure within 0.5 microseconds and reroutes the signal in reverse.

For viewers, it’s completely seamless.

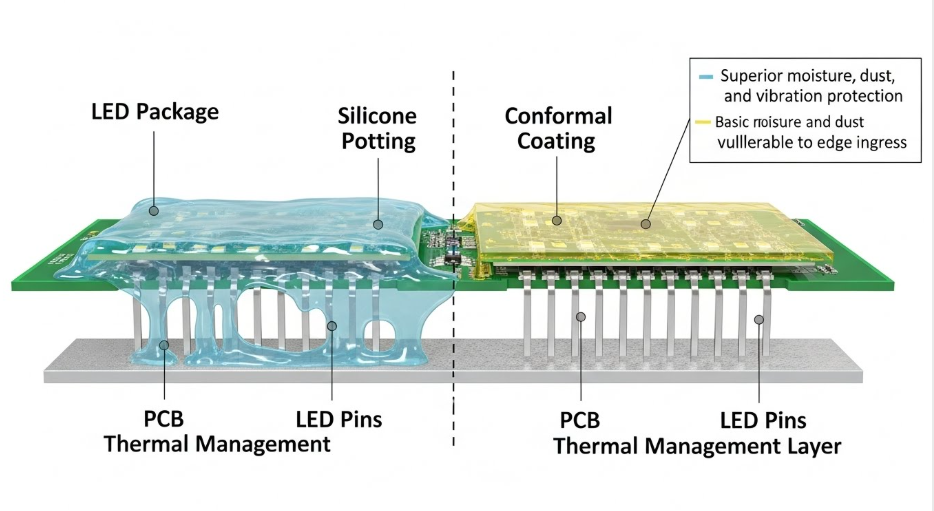

3. The Truth Behind “IP65”: Potting Process

Many displays claim IP65 but only apply surface conformal coating.

Fully Potted Modules

Sostron outdoor modules use high-thermal-conductivity silicone for pin-level full potting.

Benefits:

-

True waterproofing

-

Rapid heat transfer from driver ICs to the aluminum base

-

Significantly higher MTBF and component lifespan

Business Value: ROI and Total Cost of Ownership (TCO)

In B2B decisions, CapEx is just the tip of the iceberg.

OpEx is the monster below the surface.

Energy Consumption: The Silent Profit Killer

A 300 m² P10 outdoor display, using traditional voltage drive, can incur up to $50,000 per year in electricity costs.

Solution: Common Cathode Technology (ARES 2 Series)

Instead of supplying a flat 5V, power is delivered precisely:

-

Red: 2.8V

-

Green/Blue: 3.8V

Results

-

30–50% energy savings

-

Surface temperature reduced by 10–15°C

-

Significantly extended LED lifespan

5-Year TCO Comparison (300 m² Outdoor Stadium Display)

Assumptions: 12 hours/day operation

| Cost Component | Generic Market Display | Sostron ARES 2 | Insight |

|---|---|---|---|

| Initial CapEx | $180,000 | $210,000 | +16% upfront |

| 5-Year Power Cost | $250,000 | $150,000 | $100,000 saved |

| Cooling Infrastructure | High (AC required) | Low (natural cooling) | Lower construction cost |

| Maintenance & Spares | $20,000 | $5,000 | 70% fewer failures |

| Total TCO | $450,000 | $365,000 | $85,000 saved over 5 years |

👉 Want a precise ROI model?

Request a customized TCO calculation based on your local electricity rates.

Procurement Pitfalls: 3 Practical Tips

1. The “Sample Panel” Trap

That pristine 0.5 m² sample is handpicked.

What to Do Instead

Audit the factory. Ask to see the aging room.

Sostron runs:

-

72-hour full-white and video aging

-

Vibration testing

-

High-pressure water spray testing

2. Batch Consistency Nightmares

Three years later, you replace damaged modules—only to find the new ones are noticeably brighter.

Sostron Solution

-

Recommend 3–5% same-batch spare modules at delivery

-

Support pixel-level calibration data storage

New modules can instantly inherit old calibration data, making color and brightness perfectly consistent.

3. Structural Safety Is a Red Line

Outdoor displays don’t fear rain—they fear wind.

Engineering Proof

-

Storm Pro cabinets use vented designs to reduce wind resistance

-

High-strength die-cast aluminum construction

-

Every project includes structural calculation reports based on local historical wind speeds

FAQ: Common Industry Questions

Q1: What does a stadium LED display typically cost?

A: Prices vary widely.

-

Basic P10 outdoor steel cabinets: $500–$700 per m²

-

High-end systems like Sostron Storm Pro with die-cast cabinets, gold-wire LEDs, and high-refresh ICs: $900–$1,500 per m²

Q2: What happens if the screen goes black during a game?

A: Sostron systems use dual power + dual signal hot backup.

Even if one power module fails, the second takes over instantly.

Storm Pro also supports hot swapping, allowing technicians to replace a module in under 10 seconds without shutting down the display.

Q3: Do you have real-world reliability proof?

A: Yes. Beyond stadium projects, our Carbon Pro Series served as the main stage display at a major Chilean music festival.

Under extreme vibration, sound pressure, and long continuous operation, the system delivered zero failures, validating our industrial-grade redundancy design.

Why Choose Sostron?

Anyone can assemble a screen that lights up.

Designing one that survives five years of wind, weather, and cost pressure is the hard part.

Sostron delivers:

-

15,000 m² smart manufacturing base with fully automated SMT lines

-

14 years of export experience, compliant with CE, ETL, FCC standards

-

National High-Tech Enterprise status, 4,000 m² R&D center, multiple core patents including common-cathode energy saving

We don’t just sell LED screens—we safeguard your stadium’s visual assets.

Next Step: Take Action

Don’t let hidden costs quietly drain your budget.

[Get a 2-Hour Fast Quote]

Upload your stadium CAD drawings or basic dimensions.

Our engineers will deliver a complete solution, including structural design and cost optimization.

References:

Society of Motion Picture and Television Engineers (SMPTE) Standards

FIFA Stadium Safety & Security Regulations

About Dylan Lian

Marketing Strategic Director at Sostron