Table of Contents

ToggleTable of Contents

-

The Brutal Reality of Touring: Why “Generic” LED Screens Fail

-

Engineering at the Core: From Die-Cast Aluminum to Carbon Fiber

-

Non-Negotiable Visual Metrics: Refresh Rate, Grayscale, and Camera Compatibility

-

The Hidden Costs: Logistics, Damage, and Depreciation

-

Industry Pitfall Guide: 5 Questions Every Procurement Manager Must Ask

-

FAQ: Straight Answers on Pricing, Batches, and After-Sales Blind Spots

-

The Sostron Solution: Predictable Delivery Backed by a 15,000㎡ Smart Factory

What Is a Touring LED Video Wall?

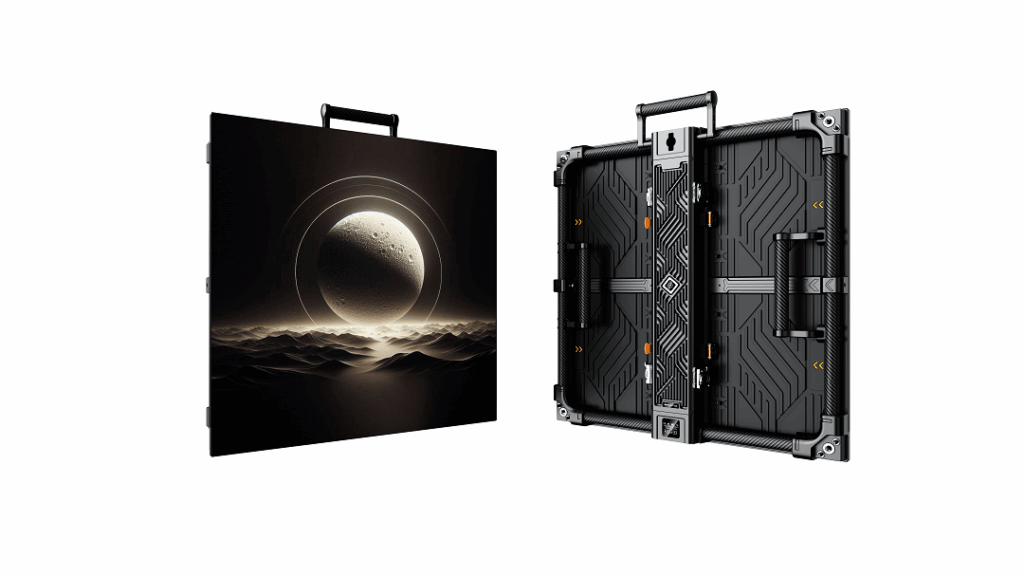

A touring LED video wall is a modular display system purpose-built for high-frequency assembly and disassembly, long-distance transportation, and extreme live event environments.

Unlike fixed-installation LED screens, touring systems use die-cast aluminum or carbon fiber cabinets, integrate quick-lock mechanisms, support ultra-high refresh rates (up to 7680Hz), and are designed with redundant signal and power backup.

The core logic is simple:

Deliver uncompromising visual impact while maximizing rental ROI by reducing weight, labor hours, and failure risk.

The Brutal Reality of Touring: Why Generic Screens Fail

At large-scale outdoor events such as music festivals, LED screens don’t just battle heat and sunlight—they endure constant mechanical stress from repeated teardown, packing, transport, and reinstallation.

Generic fixed-installation screens fail quickly on tour, typically due to:

-

Rapid pixel failure rates

Modules without reinforced corner protection are highly vulnerable during packing and transport. -

Cabinet seam distortion

Low-grade cabinets deform under repeated rigging loads, creating visible black lines or bright seams. -

On-site system crashes

Without full redundancy, a single receiver card failure can take down an entire LED chain mid-show.

On tour, failure isn’t hypothetical—it’s scheduled unless engineered out.

Engineering at the Core: From Die-Cast Aluminum to Carbon Fiber

The premium cost of touring LED screens is driven by structural engineering, not marketing. Today’s market follows three main technical paths:

Table 1: Mainstream Touring LED Solutions – Specification Comparison

| Feature | Standard Rental (ARES / Storm Series) | High-End Carbon Fiber (Carbon Pro) | Creative Flexible (SPad Pro2) |

|---|---|---|---|

| Cabinet Material | Die-cast aluminum | High-modulus carbon fiber | Reinforced flexible polymer |

| Weight per Cabinet | 7–12 kg | < 5 kg | 4–6 kg |

| Max Hanging Height | 10–15 m | 20 m+ | 8–10 m |

| Core Advantage | Cost-efficiency & stability | One-person install, major air freight savings | 360° S-curves & arcs |

| Typical Use Case | Commercial rental, highways | World-class tours, XR studios | Auto shows, artistic stages |

For export-focused manufacturers, Carbon Pro delivers a decisive advantage:

30–40% lower international air freight costs, which translates directly into net profit on global tours.

Weight is money. Lighter screens travel farther—and rent longer.

1. Setup Project Data

e.g., 1.25, 2.5, 3.9, 4.8

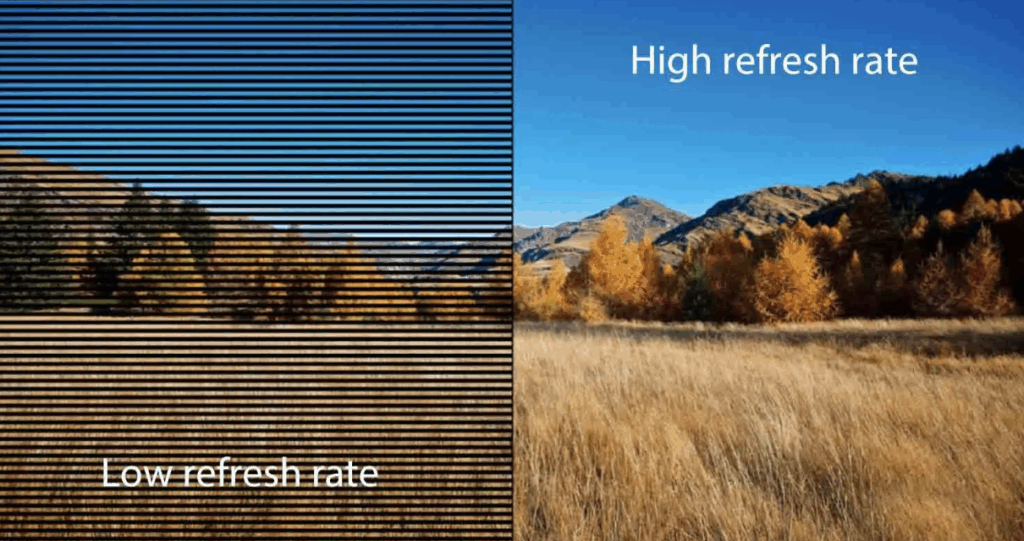

Non-Negotiable Visual Metrics: Refresh Rate & Camera Compatibility

In 2025, 3840Hz refresh rate is the minimum baseline.

For high-end touring productions, 7680Hz is standard.

Key performance thresholds include:

-

Low scan ratio

Essential for eliminating camera scan lines and Moiré artifacts in live broadcast. -

16-bit grayscale processing

Preserves color depth at low brightness—critical for immersive XR stages such as the Sostron HIMA series.

If your screen looks fine to the eye but fails on camera, it fails—period.

Hidden B2B Costs: Logistics, Damage, and Depreciation

As a supply chain director, I strongly advise buyers to evaluate TCO (Total Cost of Ownership)—not just unit price.

Key cost drivers:

-

Logistics efficiency

A 200㎡ Carbon Pro system typically requires two fewer standard containers than conventional touring screens. -

Maintenance redundancy

The Sostron HIMA series supports full front and rear service.

In real touring conditions, a single module replacement must take under 30 seconds. -

Residual value

Screens using premium LED chips (gold-wire bonding) retain 90%+ brightness and color consistency after 3 years, achieving 25% higher resale value than low-end alternatives.

Cheap screens depreciate fast. Good screens earn twice.

Industry Pitfall Guide: 5 Questions Every Buyer Must Ask

-

“How many fatigue cycles has your quick-lock system passed?”

Quality locks should withstand 5,000+ open-close cycles without deformation. -

“How do you ensure color temperature consistency across batches?”

Look for strict LED binning records and factory-level calibration systems. -

“How many PCB layers, and is conformal coating applied?”

This determines survivability in humid, coastal, or tropical touring environments. -

“Can your 15,000㎡ facility pass third-party factory audits?”

This separates real manufacturers from trading companies with empty offices.

If they hesitate on any of these—walk away.

FAQ: Straight Answers on Pricing & After-Sales Support

Q: Why are you 20% more expensive than some small Shenzhen factories?

A: That 20% difference is usually hidden in:

-

Aluminum grade (low hardness leads to cabinet deformation)

-

Gold-wire vs copper-wire LEDs (2× lifespan difference)

-

Reliability testing and R&D investment

Sostron operates a 4,000㎡ R&D center, where every touring product undergoes vibration and transport simulation testing.

Cheap screens skip testing. Tours pay the price.

Q: What happens if a screen fails during a tour?

A:

We provide CMS-based cloud monitoring for early fault detection.

For key clients, we also offer:

-

On-site resident engineers

-

Regional spare-part warehouses

Tour downtime is not acceptable—and we treat it that way.

7. The Sostron Solution: 14 Years of Predictable Delivery

Sostron doesn’t just manufacture hardware—we deliver certainty in live performance execution.

Why Sostron?

-

15,000㎡ smart manufacturing base

Ensures delivery timelines for large-scale projects, including major African highway LED deployments. -

Complete product matrix

-

Outdoor flagship: ARES 2 (common-cathode design, up to 50% lower operating costs)

-

High-end touring: Carbon Pro (ultra-lightweight)

-

Creative display: Crystal Transparent LED (high transparency, no light blockage)

-

Table 3: Sostron Standards vs Industry Average

| Dimension | Industry Average | Sostron Standard |

|---|---|---|

| Core Facility Size | 3,000–5,000㎡ | 15,000㎡ manufacturing + 4,000㎡ R&D |

| Delivery Experience | 3–5 years | 14 years of global project execution |

| Protection | Single-side coating | IP65 dual-side resin encapsulation (ARES) |

| Heat Dissipation | Fan-dependent | Full-aluminum passive cooling + thermal simulation |

Conclusion: Choosing the Right Screen Is Choosing Profit

A touring LED video wall is not a consumable—it is a revenue-generating asset.

Choosing Sostron, a National High-Tech Enterprise, means backing your investment with 14 years of proven engineering, manufacturing depth, and global delivery experience.

Next Steps

-

Need accurate pricing?

→ Get the 2026 Touring Series Price List -

Want to see real products?

→ Schedule a visit to our 15,000㎡ smart factory -

Need technical guidance?

→ Book a 1-on-1 consultation with our senior engineers

Old-school engineering, forward-looking execution. That’s how touring screens survive—and make money.

References:

UL 8750 – LED Equipment for Use in Lighting Products

FCC Part 15 – Radio Frequency Devices

About Dylan Lian

Marketing Strategic Director at Sostron