Table of Contents

-

Understanding the True Cost of Outdoor LED Billboards

-

Technical Specifications Comparison & Application Scenarios

-

Supply Chain Cost Structure & Hidden Risks

-

Industry Insider Tips: How to Avoid Common Traps

-

Frequently Asked Questions

-

Sostron Ares Series

-

Actionable Recommendations

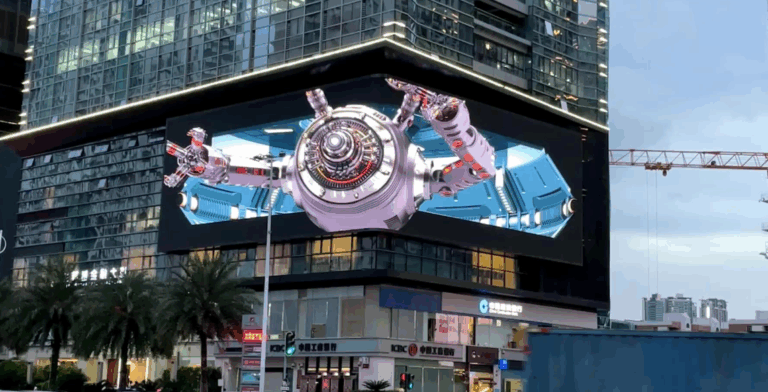

Purchasing LED billboards wholesale from China is not just about comparing upfront prices. The real total cost of ownership (TCO) is often buried in technical specifications, maintenance agreements, and supply chain risks. This guide breaks down the pricing structure of outdoor LED billboards, exposes industry insider knowledge, and provides a data-driven decision framework to help you reduce costs by up to 30% while ensuring stable operation for at least five years.

Understanding the True Cost of Outdoor LED Billboards

Many buyers focus solely on the price per square meter and overlook nearly 40% of hidden costs in total ownership. Take a 100-square-meter P10 outdoor LED screen as an example: the initial hardware investment accounts for only 55% of the five-year total cost. Electricity (22%), maintenance (15%), and component replacement (8%) make up the remaining 45%.

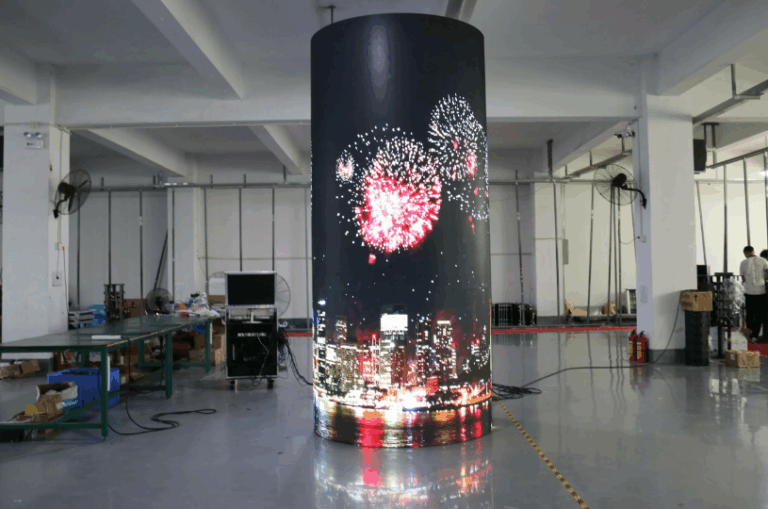

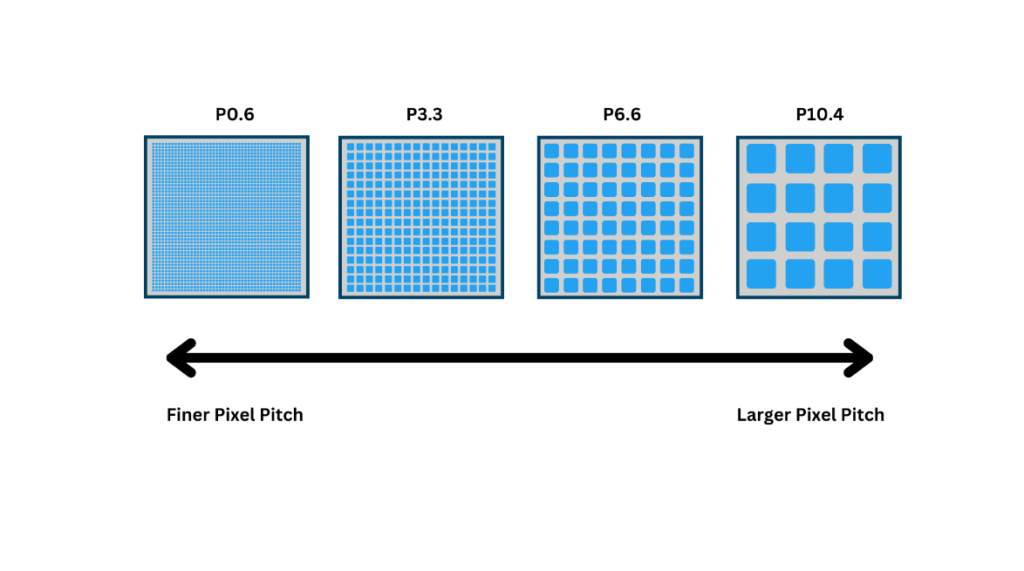

The core of LED billboard pricing lies in pixel pitch and LED chip quality. For instance, a P3.9 screen requires 62,500 pixels per square meter, over six times that of a P10 screen (10,000 pixels/m²). This alone drives material costs to be roughly 2.3 times higher. However, chasing finer pixel pitch blindly is unnecessary. For highway billboards viewed from over 50 meters, P16 typically delivers the best cost-performance ratio.

Technical Specifications Comparison & Application Scenarios

Choosing the right technical specifications directly affects display performance and return on investment. The table below compares common configurations across typical application scenarios:

| Parameter | P6 (Urban Areas) | P10 (Highways) | P16 (Rural Areas) | Ares Series P3.9 |

|---|---|---|---|---|

| Pixel Density | 27,777 dots/m² | 10,000 dots/m² | 3,906 dots/m² | 65,536 dots/m² |

| Optimal Viewing Distance | 6–30 m | 10–50 m | 16–100 m | 3.9–20 m |

| Brightness | 6,000 nits | 5,500 nits | 5,000 nits | 10,000 nits |

| Power Consumption | 380 W/m² | 320 W/m² | 280 W/m² | 220 W/m² |

| 5-Year Electricity Cost | $14,400 | $11,800 | $10,300 | $8,100 |

| Price (USD/m²) | $1,200–1,500 | $800–1,000 | $600–750 | $1,800–2,200 |

Data source: China LED Display Industry Report, Q3 2025

The Ares Series stands out with its 10,000-nit ultra-high brightness and 220 W/m² low power consumption, enabled by a full aluminum cabinet design and common-cathode technology. Compared with traditional products, this reduces energy usage by 35%. In an outdoor project in southern France, a 6 m² Ares P3.9 screen has been running continuously for two years, with measured annual electricity costs 28% lower than the industry average.

Supply Chain Cost Structure & Hidden Risks

A complete LED billboard supply chain typically includes five layers:

-

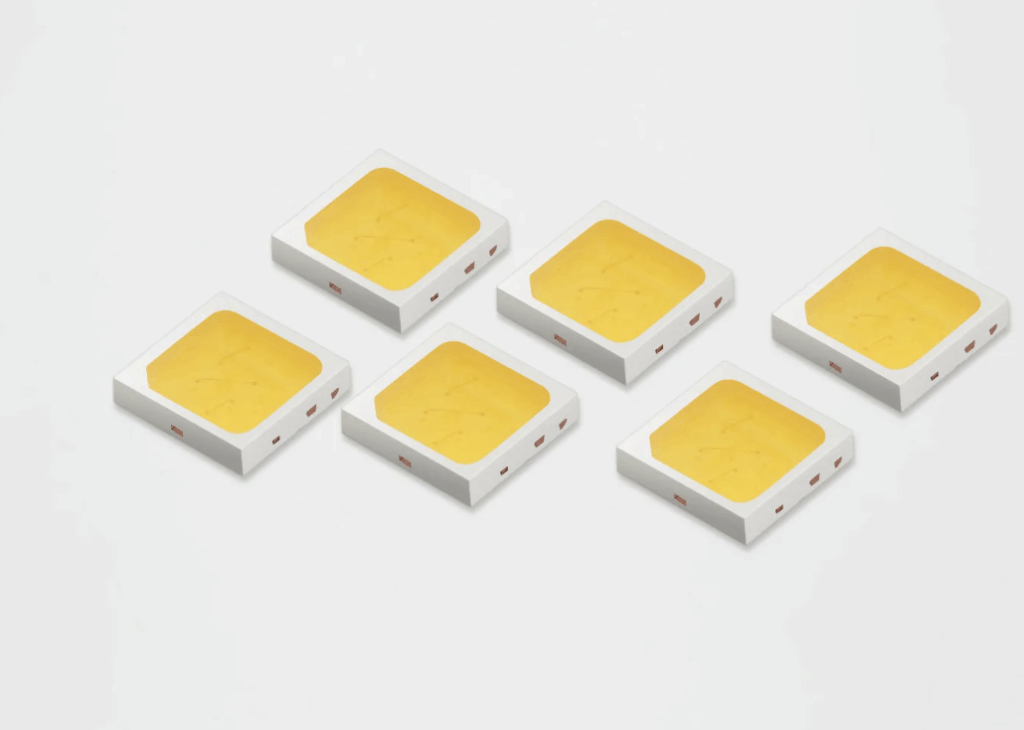

Raw material suppliers (LED chips: ~35% of cost)

-

Module manufacturers (25%)

-

System integrators (15%)

-

Distributors (15%)

-

Installation service providers (10%)

Each layer usually adds an 8–12% margin, resulting in a final price that is 2–2.5 times the factory ex-works price.

One of the most overlooked risks is LED chip bin consistency. Low-cost suppliers often mix different chip bins, leading to 15–20% brightness deviation within six months. The Ares Series uses top-bin Epistar chips with wavelength deviation ≤3 nm, ensuring color uniformity for 30,000 hours.

Another hidden cost is maintenance response time. Many suppliers advertise a “2-year warranty,” but this often covers parts only—not on-site labor. Overseas buyers may face 4–6 weeks of downtime during failures. Sostron’s global service network guarantees on-site response within 72 hours in over 90 countries. This was proven in a Brazilian highway project, where an unexpected voltage surge was resolved within 48 hours.

Industry Insider Tips: How to Avoid Common Traps

1. The Pixel Pitch Myth

Sales reps often push the idea that “smaller pixel pitch is always better.” In reality, for highway billboards viewed from 100 meters, P10 is more cost-effective than P8. Use the “1000 Rule”:

Optimal viewing distance (m) ≈ pixel pitch (mm) × 1000

This simple rule helps avoid over-investment.

1. Setup Project Data

e.g., 1.25, 2.5, 3.9, 4.8

2. Fake Certifications

About 80% of suppliers claim CE/RoHS compliance, but only 30% can provide valid test reports. Always request certificate numbers and verify them in the EU’s official database.

3. Maintenance Contract Pitfalls

A reliable maintenance agreement should clearly specify:

-

LED chip warranty: ≥50,000 hours (brightness decay <30%)

-

Power supply replacement cycle: 3 years

-

On-site service response time: ≤72 hours

-

Calibration service: 2 times per year

Frequently Asked Questions

Q: What is the realistic price range for high-quality wholesale LED billboards from China?

A: For P10 outdoor screens using Epistar chips and IP65 protection, a reasonable factory price is $850–1,100 per m². Prices below $750 usually indicate recycled chips or compromised thermal design.

Q: How can I verify the actual power consumption of a supplier’s product?

A: Request a “100% white screen power consumption test report” and check the power factor (PF). PF should be ≥0.95. Low-quality power supplies with PF below 0.85 can increase real electricity costs by 15%.

Q: What payment terms are most favorable for buyers?

A: Industry standard is 30% deposit, 60% after factory acceptance, and 10% after three months of operation. Avoid paying more than 50% upfront to reduce delivery risk.

Q: Does Sostron support custom cabinet sizes?

A: Yes. The Ares Series offers five standard cabinet sizes (from 500×500 mm to 1000×2000 mm) and supports custom designs. A project in southern France used a bespoke 6 m² seamless solution to match a historic building façade.

Sostron Ares Series: Technical Advantages & Project Cases

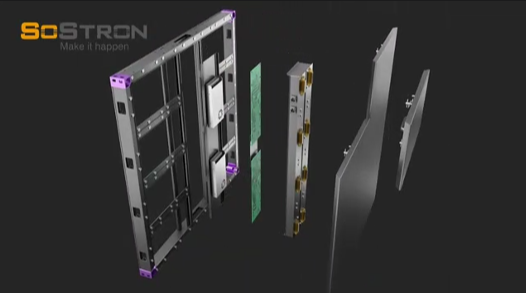

The Ares Series outdoor fixed-installation LED displays integrate 14 years of Sostron’s R&D expertise, targeting the high-end outdoor advertising market. Key advantages include:

-

Ultra-light aluminum cabinets: Only 28 kg/m², reducing structural costs by 20% compared to steel cabinets. The full aluminum design achieves IP66 protection without additional waterproof fans.

-

Intelligent energy-saving system: Ambient light sensors automatically adjust brightness between 1,000 and 10,000 nits. Common-cathode driving reduces power consumption by 30%, saving $4,200 per year for a 100 m² screen.

-

Modular maintenance design: Front-service modules allow one-person replacement in 3 minutes, cutting labor costs by 60%. Built-in CMS cloud monitoring predicts potential failures 7–14 days in advance.

In a coastal project in southern France, the Ares P3.9 screen has operated stably for 27 months under high heat (42°C) and humidity (90%). Its 10,000-nit brightness ensures clear visibility even under intense Mediterranean sunlight, while the aluminum heat dissipation design eliminates the need for air conditioning. Overall, total ownership cost is 28% lower than comparable European brands.

Actionable Recommendations

-

Technical Evaluation: Use our free Pixel Pitch Calculator to determine the optimal specification based on installation location and viewing distance.

-

Factory Audit: Request a virtual tour of Sostron’s 15,000 m² manufacturing facility and 4,000 m² R&D center to verify production capability.

-

Sample Testing: Order a 1 m² sample for 72-hour high-temperature (50°C) and low-temperature (–20°C) cycling tests to assess stability.

-

Customized Solutions: Contact our technical team for tailored designs, including structural engineering and content management systems.

Click the link below to receive your exclusive “China LED Billboard Project Checklist”, designed to help you avoid 90% of procurement risks.

References: